Polyimide blend compact dehumidification film and preparation method thereof

A technology of polyimide and blends, which is applied in the field of air conditioning and can solve problems such as poor water absorption and insufficient mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

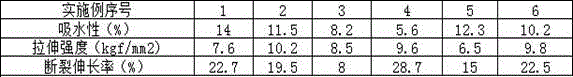

Examples

specific Embodiment 1

[0024] Specific example 1: Mix the monomeric raw materials 6-amino-1-naphthalenesulfonic acid and 1,5-dihydroxynaphthalene at a molar ratio of 1:0.7, add an initiator, and generate a preform with a relative molecular weight of less than 40,000 at a temperature of 50°C. polymer; secondly, the prepolymer produced is desolvated, dried, mixed with polyimide at a weight ratio of 10:100, dissolved, and film-formed on a glass plate; finally, the solvent is removed and dried to obtain a 0.03mm Polymer film.

specific Embodiment 2

[0025] Specific Example 2: Mix the monomeric raw materials 8-naphthylamine-1-sulfonic acid and 2,3-dihydroxynaphthalene in a molar ratio of 1: 1.5, add an initiator, and generate a preform having a relative molecular weight of less than 40,000 at a temperature of 80°C. polymer; secondly, the prepolymer produced is desolvated, dried, mixed with polyimide at a weight ratio of 100:100, dissolved, and film-formed on a glass plate; finally, the solvent is removed and dried to obtain a 0.10mm Polymer film.

specific Embodiment 3

[0026] Specific example 3: Mix the monomer raw material 7-amino-1,3-naphthalene disulfonic acid and 1,4-dihydroxynaphthalene at a molar ratio of 1:1, add an initiator, and generate a relative molecular weight less than 40000 prepolymer; secondly, the prepolymer produced is desolventized, dried, mixed with polyimide at a weight ratio of 60:100, dissolved, and film-formed on a glass plate; finally, the solvent is removed and dried to obtain 0.07mm polymer film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com