Internal anti-corrosion method of cement pipe, anti-corrosion coating and preparation method thereof

A technology for anti-corrosion coatings and anti-corrosion coating layers, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of no obvious protective effect against oil erosion, poor adhesion of concrete pipes, easy leaching, etc., and achieve a good surface Protective effect, convenient steps, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

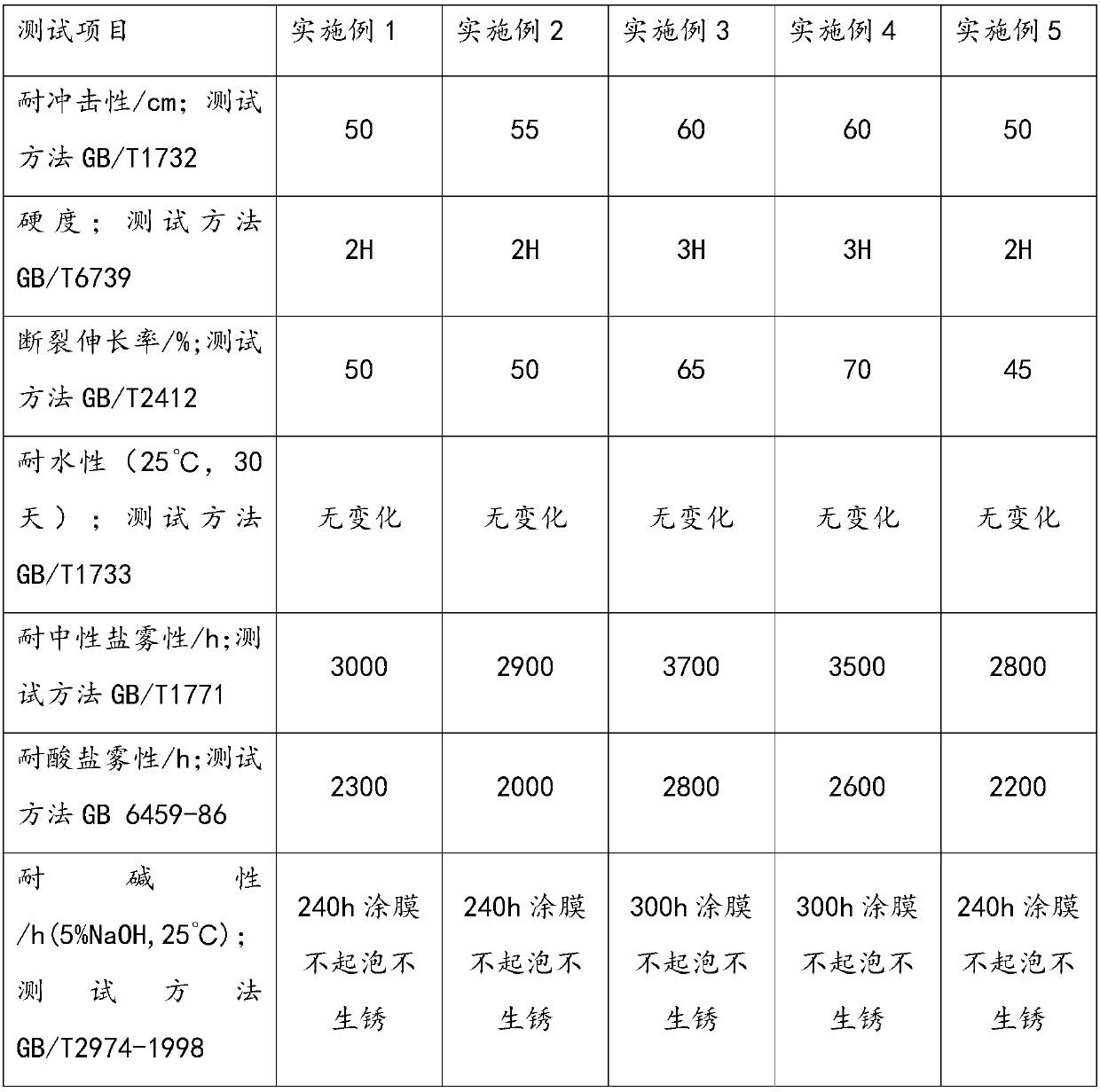

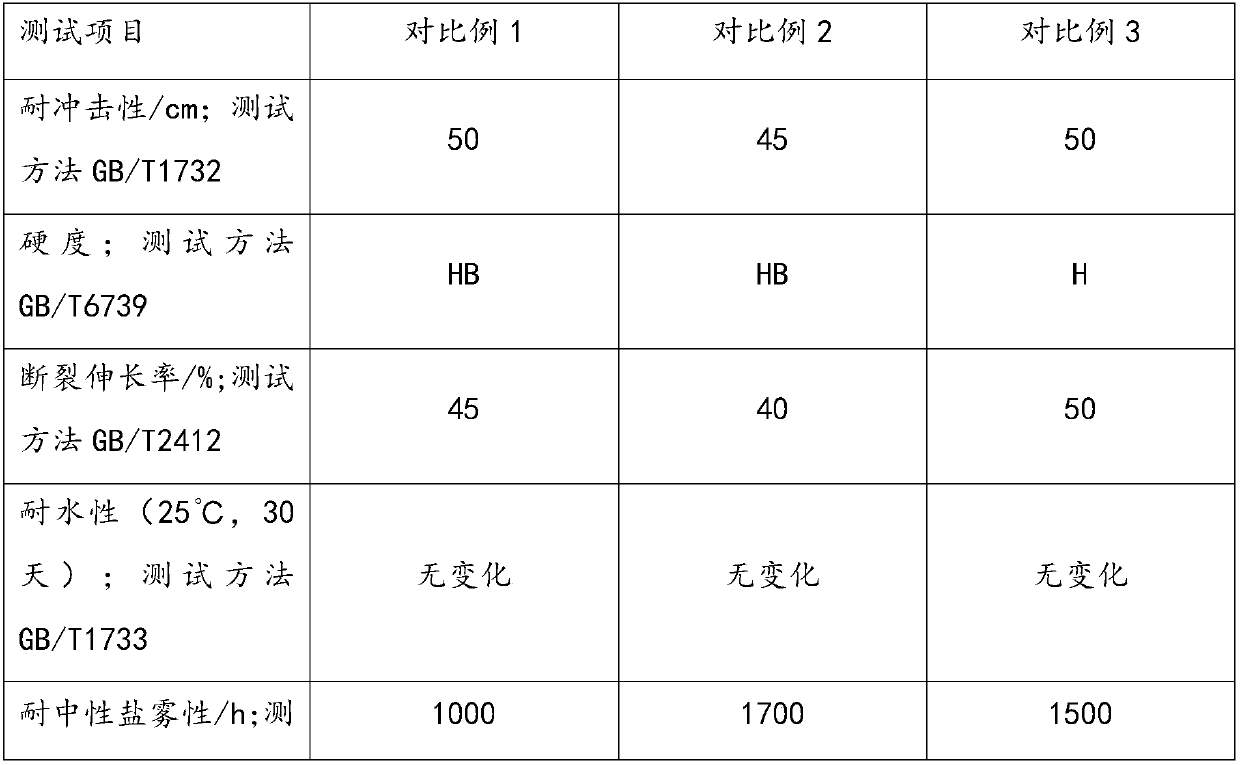

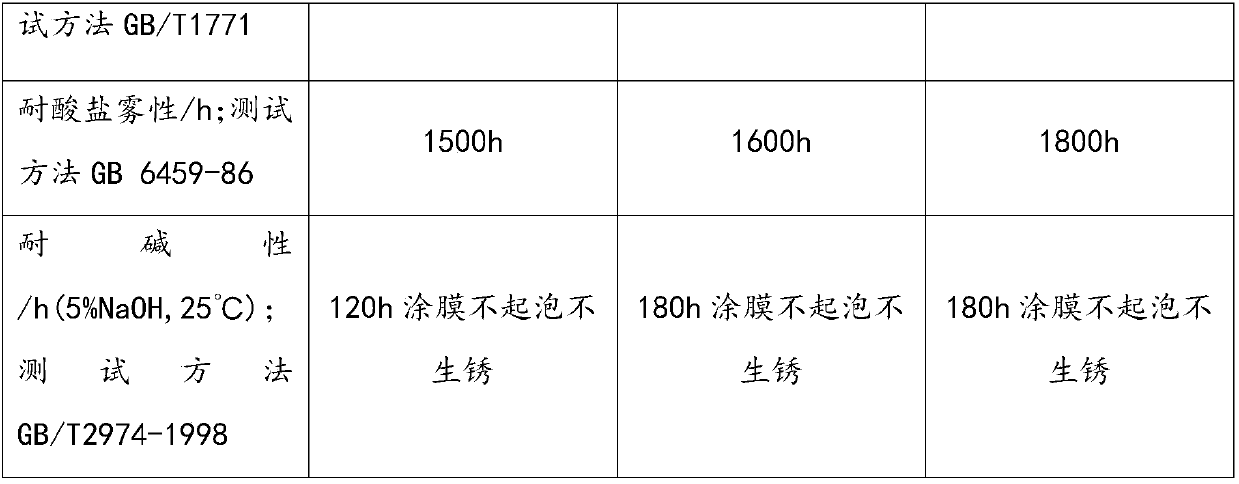

Examples

Embodiment 1

[0040] In parts by mass: 30 parts of epoxy resin, 5 parts of reactive diluent, 10 parts of titanium dioxide, 3 parts of barium sulfate, 5 parts of red iron oxide, 0.5 parts of nano-zinc oxide, 0.5 parts of additives, 20 parts of curing agent and 15 parts of Parts of non-reactive diluent, weigh appropriate amount of raw materials for each component;

[0041] Among them, the epoxy resin is: E-51 bisphenol A epoxy resin, the reactive diluent is: allyl glycidyl ether; the additives are: wetting and dispersing agent AT-203, leveling agent BYK-354 and defoamer Silicone defoamer, wherein the mass ratio of wetting dispersant, leveling agent and defoamer is 1:1:1; the curing agent is: cashew nut shell epoxy curing agent; the non-reactive diluent is: xylene A mixed solution with petroleum ether, wherein the volume ratio of xylene to petroleum ether is 1:2.

[0042] Then, prepare the anticorrosion coating according to the following steps:

[0043] (1) At room temperature, add epoxy res...

Embodiment 2

[0048] According to the mass fraction: 50 parts of bisphenol A epoxy resin, 10 parts of reactive diluent, 15 parts of titanium dioxide, 8 parts of barium sulfate, 15 parts of red iron oxide, 5 parts of nano-zinc oxide, 1 part of auxiliary agent, 30 parts of curing agent And 25 parts of non-reactive diluents, weigh appropriate amount of raw materials of each component respectively;

[0049] Among them, the epoxy resin is: E-44 epoxy resin; the reactive diluent is: butyl glycidyl ether; the additives are: wetting and dispersing agent AT-203, leveling agent BYK-354 and defoaming agent silicone defoaming Among them, the mass ratio of wetting and dispersing agent, leveling agent and defoaming agent is 1:2:1; the curing agent is: polyamide curing agent; the non-reactive diluent is: mixed solution of xylene and petroleum ether , wherein the volume ratio of xylene to petroleum ether in milliliters is 1:1.

[0050] Then, prepare the anticorrosion coating according to the following ste...

Embodiment 3

[0056] In parts by mass: 40 parts of epoxy resin, 8 parts of reactive diluent, 12 parts of titanium dioxide, 6 parts of barium sulfate, 10 parts of red iron oxide, 3 parts of nano-zinc oxide, 0.8 parts of auxiliary agent, 25 parts of curing agent and 20 parts of Parts of non-reactive diluent, weigh an appropriate amount of each raw material component;

[0057] Among them, the epoxy resin is E-42 bisphenol A epoxy resin; the reactive diluent is: dimethyl glycidyl ether; the additives are: wetting and dispersing agent AT-203, leveling agent BYK-354 and defoamer organic Silicon defoamer, wherein, the mass ratio of wetting dispersant, leveling agent and defoamer is 1:2:2; the curing agent is: cashew nut shell epoxy curing agent; the non-reactive diluent is: xylene and A mixed solution of petroleum ether, wherein the volume ratio of xylene to petroleum ether in milliliters is 2:3.

[0058] Then, according to the method described in Example 2, the anticorrosion coating of Example 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com