Rare earth graphene aluminum alloy type conductive wire material and preparation method thereof

A graphene and aluminum alloy technology, applied in the direction of conductive materials, conductive materials, metal/alloy conductors, etc., can solve the problems of uneven dispersion and agglomeration, poor electrical conductivity, and difficulty in mass industrial production, and achieve mechanical properties Good, widely used effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

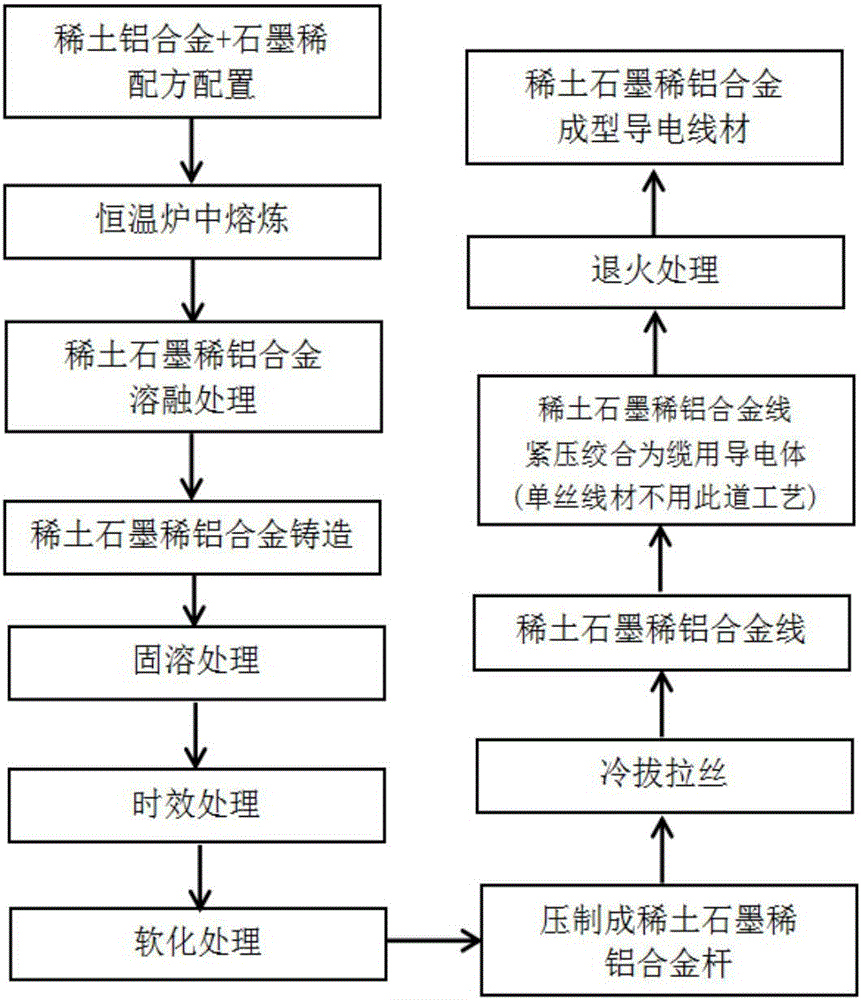

Method used

Image

Examples

Embodiment 1

[0018] (1) A conductive wire rod of a rare earth graphene aluminum alloy, which is an Al-Fe-C-S-R aluminum alloy, wherein the weight ratio of each element component is: 0.49wt% Fe, 2.5wt% C, S including 0.02wt% V and 0.05wt% Cr, 0.24wt% R; the balance is Al; C is a single-layer carbon element graphene; a preparation method of a conductive wire of a rare earth graphene aluminum alloy: the prepared aluminum Fe alloy, aluminum C alloy, aluminum S alloy, aluminum R alloy and 99.8% pure aluminum are placed in the melting furnace according to the proportion of (1), and the melting temperature is 760°C;

[0019] (2) Melting treatment of rare earth graphene aluminum alloy: the smelted rare earth graphene aluminum alloy metal liquid is added to the refining agent in a 750°C holding furnace, and the high temperature resistant alloy steel double blade stirrer is used to stir at a rate of 30 rpm for 30 After stirring, the temperature was raised to 890°C and kept for 60 minutes.

[0020] ...

Embodiment 2

[0030] (1) A conductive wire rod of a rare earth graphene aluminum alloy, which is an Al-Fe-C-S-R aluminum alloy, wherein the weight ratio of each element component is: 0.45wt% Fe, 2.1wt% C, and 0.21wt% S V, 0.3wt% R; the remainder is Al; C is single-layer carbon element graphene;

[0031] (2) Melting rare earth graphene aluminum alloy: put the prepared aluminum Fe alloy, aluminum C alloy, aluminum S alloy, aluminum R alloy and 99.8% pure aluminum in the melting furnace according to the ratio of (1) Refining, the melting temperature is 755°C.

[0032] (3) Rare earth graphene aluminum alloy melting treatment: Add refining agent to the smelted rare earth graphene aluminum alloy metal liquid in a 750°C holding furnace, and stir for 40 minutes at a rate of 36 rpm with a high temperature resistant alloy steel double blade stirrer After the stirring is completed, the temperature is raised to 850° C. and the temperature is kept for 60 minutes.

[0033](4) Casting the rare earth gra...

Embodiment 3

[0042] (1) A rare-earth graphene aluminum alloy conductive wire rod is an Al-Fe-C-S-R aluminum alloy, wherein the weight ratio of each element component is: 0.31wt% Fe, 1.8wt% C, and S is 0.13wt% Ti And the Ni of 0.05wt%, the R of 0.11wt%; The remainder is Al; C is single-layer carbon element graphene;

[0043] (2) Melting rare earth graphene aluminum alloy: put the prepared aluminum Fe alloy, aluminum C alloy, aluminum S alloy, aluminum R alloy and 99.8% pure aluminum in the melting furnace according to the ratio of (1) Refining, the melting temperature is 750°C.

[0044] (3) Rare earth graphene aluminum alloy melting treatment: Add refining agent to the smelted rare earth graphene aluminum alloy metal liquid in a 750°C holding furnace, and stir for 30 minutes at a rate of 30 rpm with a high temperature resistant alloy steel double blade stirrer After the stirring is completed, the temperature is raised to 890° C. and the temperature is kept for 60 minutes.

[0045] (4) Cas...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap