Rolling method for high-strength aluminum alloy plate

An aluminum alloy plate and high-strength technology, which is applied in the field of aluminum alloy materials, can solve the problems of reduction, durability of aluminum alloy materials, and damage tolerance that cannot be improved simultaneously, so as to eliminate dendrite segregation, improve microhardness, and realize alloy The effect of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The rolling method of the high-strength aluminum alloy plate of the present invention comprises the following steps:

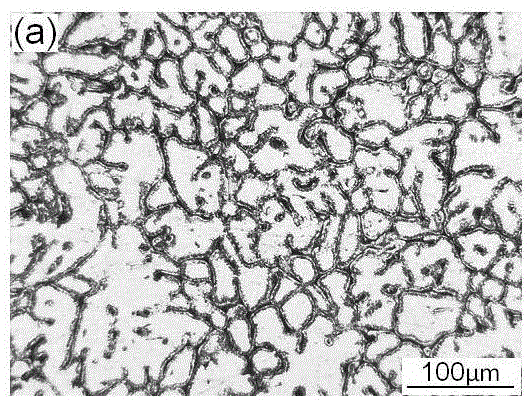

[0027] A. Homogenize and anneal the Al-Mg-Si-Cu alloy billet after refining at 500°C for 12 hours;

[0028] B. Control the temperature of the Al-Mg-Si-Cu alloy billet after annealing at 390°C. After the temperature inside and outside of the Al-Mg-Si-Cu alloy billet is uniform, perform a single-pass 15% hot rolling pre-rolling Deformation, roll rolling line speed is 0.4m / min, continue to control the temperature of the Al-Mg-Si-Cu alloy billet to 390 ° C, and then carry out single-pass 70% large reduction rolling deformation, roll rolling The line speed is 0.4m / min, and the thick slab is obtained by rolling, and the thick slab is air-cooled to room temperature;

[0029] C. The cooled thick slab is subjected to solution treatment at 450°C for 0.5h, and then water quenched;

[0030] D. Pre-aging the thick slab after water quenching at 150°C for 10h, and t...

Embodiment 2

[0035] The rolling method of the high-strength aluminum alloy plate of the present invention comprises the following steps:

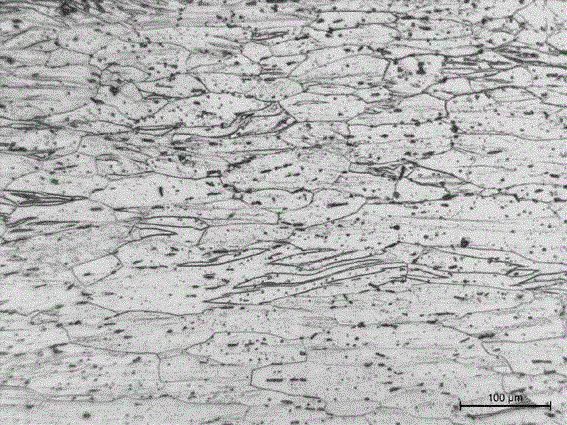

[0036] A. Homogenize and anneal the Al-Mg-Si-Cu alloy billet after refining at 520°C for 18 hours;

[0037] B. Control the temperature of the Al-Mg-Si-Cu alloy billet after annealing at 395°C. After the temperature inside and outside of the Al-Mg-Si-Cu alloy billet is uniform, perform a single-pass 16% hot rolling pre-rolling Deformation, roll rolling line speed is 0.5m / min, continue to control the temperature of Al-Mg-Si-Cu alloy ingot billet to 395°C, and then carry out single-pass 72% large reduction rolling deformation, roll rolling The line speed is 0.5m / min, and the thick slab is obtained by rolling, and the thick slab is water-cooled to room temperature;

[0038] C. The cooled thick slab is subjected to solution treatment at 470°C for 0.8h, and then water quenched;

[0039] D. Pre-aging the thick slab after water quenching at 180°C for 12h, and...

Embodiment 3

[0044] The rolling method of the high-strength aluminum alloy plate of the present invention comprises the following steps:

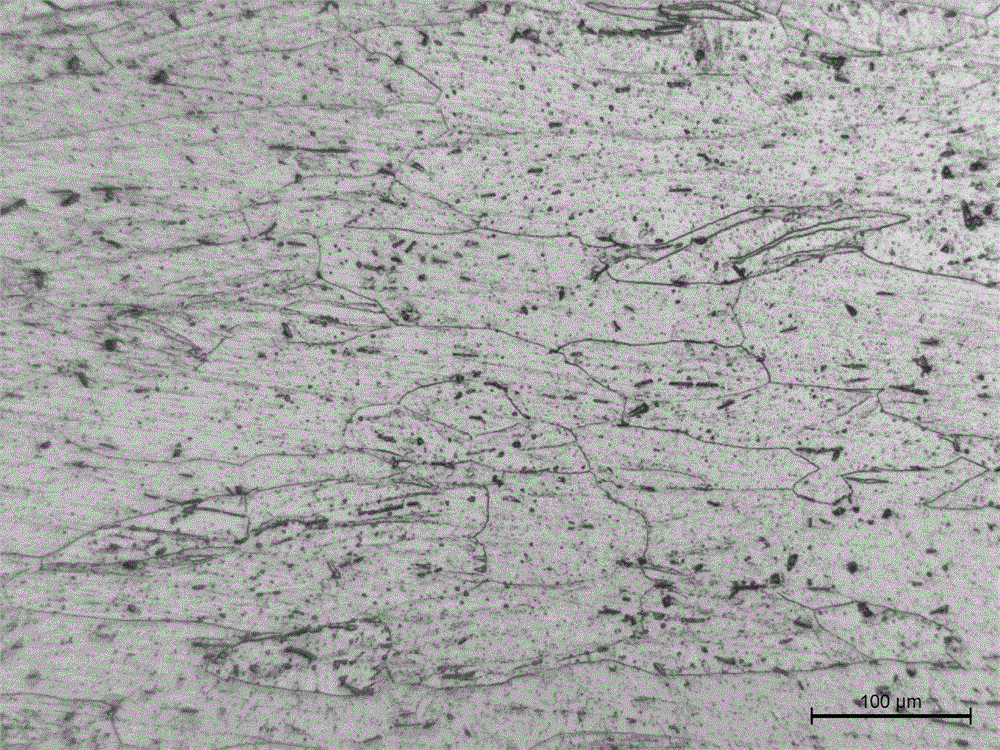

[0045] A. Homogenize and anneal the Al-Mg-Si-Cu alloy billet after refining at 550°C for 24 hours;

[0046] B. Control the temperature of the Al-Mg-Si-Cu alloy billet after annealing at 400°C. After the temperature inside and outside of the Al-Mg-Si-Cu alloy billet is uniform, perform a single-pass 17% hot rolling pre-rolling Deformation, the rolling speed of the rolls is 0.6m / min, continue to control the temperature of the Al-Mg-Si-Cu alloy billet to 400°C, and then carry out a single pass of 75% large reduction rolling deformation, roll rolling The line speed is 0.6m / min, and the thick slab is obtained by rolling, and the thick slab is air-cooled to room temperature;

[0047] C. The cooled thick slab is subjected to solution treatment at 510°C for 1.2h, and then water quenched;

[0048] D. Pre-aging the thick slab after water quenching at 200°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com