A lightweight high-strength aluminum alloy

An aluminum alloy and high-strength technology, applied in the field of metal materials, can solve problems such as low strength and hardness, poor toughness, and inability to withstand impact forces, and achieve the elimination of coarse non-equilibrium solidification eutectic and dendrite segregation, and the precipitation of strengthening phases with reasonable distribution , The effect of heat treatment process improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

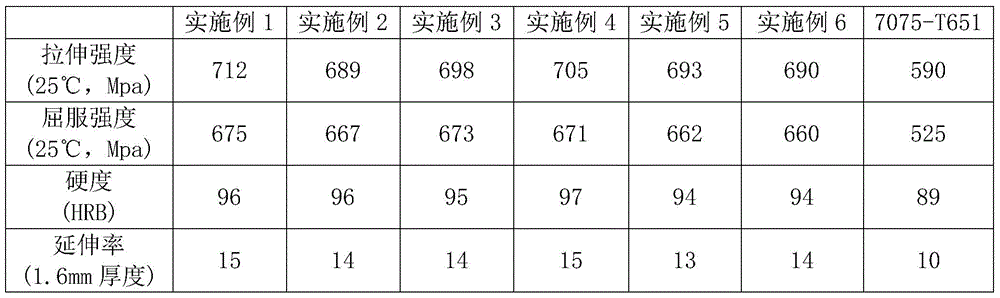

Examples

Embodiment 1

[0027] S1: Smelting, weighing each raw material according to its composition, adding the aluminum ingot into the melting furnace and heating it to 750°C to make it completely melted, then adding other raw materials in order of melting point from high to low, and wait until the other raw materials are completely After melting, all the raw materials were added and completely melted, and all the slag removal operations were carried out, and the alloy melt was obtained at 720°C for 30 minutes, and poured. After the alloy melt solidified, the mold was opened, and the ingot was air-cooled to room temperature; During the solidification process of the melt, the alloy melt is vibrated by knocking on the mold, and the melting process of each raw material is carried out in a sealed space;

[0028] S2: Homogenization, place the ingot obtained in S1 in a holding furnace at room temperature, and raise the temperature to 400°C at a constant speed of 60°C / h, and then heat it at a constant spee...

Embodiment 2

[0032]S1: Smelting, weighing each raw material according to its composition, adding the aluminum ingot into the melting furnace and heating it to 700°C to make it completely melted, then adding other raw materials in order of melting point from high to low, and wait until the other raw materials are completely After melting, all the raw materials were added and completely melted, and all the slag removal operations were carried out, and the alloy melt was obtained at 680°C for 2 hours, and poured. After the alloy melt solidified, the mold was opened, and the ingot was air-cooled to room temperature; During the solidification process of the melt, the alloy melt is vibrated by knocking on the mold, and the melting process of each raw material is carried out in a sealed space;

[0033] S2: Homogenization, place the ingot obtained in S1 in a holding furnace at room temperature, and raise the temperature to 400°C at a constant speed of 60°C / h, and then heat it at a constant speed of...

Embodiment 3

[0037] S1: Melting, weighing each raw material according to its composition, adding the aluminum ingot into the melting furnace and heating it to 720°C to make it completely melted, then adding other raw materials in order of melting point from high to low, and wait until the other raw materials are completely After melting, all the raw materials were added and completely melted, and all the slag removal operations were carried out, and the alloy melt was obtained at 700°C for 1 hour, and poured. After the alloy melt solidified, the mold was opened, and the ingot was air-cooled to room temperature; During the solidification process of the melt, the alloy melt is vibrated by knocking on the mold, and the melting process of each raw material is carried out in a sealed space;

[0038] S2: Homogenization, place the ingot obtained in S1 in a holding furnace at room temperature, and raise the temperature to 400°C at a constant speed of 60°C / h, and then heat it at a constant speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com