A kind of cast aluminum-silicon alloy with high thermal conductivity and preparation method thereof

A technology of casting aluminum-silicon alloy with high thermal conductivity, which is applied in the field of metal materials, can solve problems such as thermal conductivity gap, achieve the effects of improving fluidity and castability, increasing alloy strength and corrosion resistance, and increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

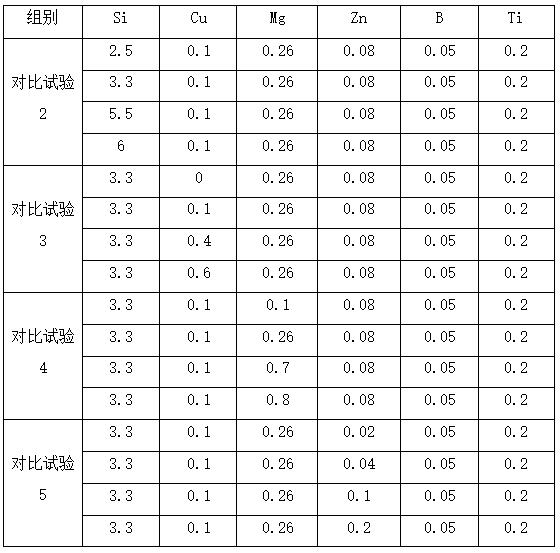

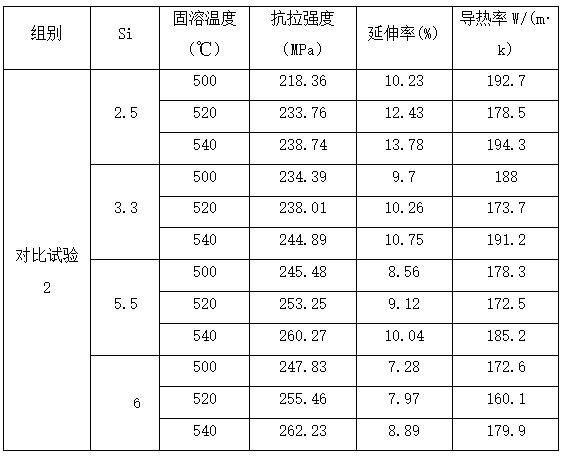

Examples

Embodiment 1

[0025] A cast aluminum-silicon alloy with high thermal conductivity, composed of the following elements by weight: Si: 3.3%, Cu: 0.10%, Mg: 0.26%, Zn: 0.08%, Ti: 0.05%, B: 0.2%, others The total sum of impurities is not more than 0.02%, and the balance is Al.

[0026] The preparation method of the cast aluminum-silicon alloy with high thermal conductivity comprises the following steps:

[0027] 1) Drying: Select pure aluminum ingots with a purity greater than 99.5%, Al-Si master alloys, Al-Cu master alloys, magnesium ingots with a purity greater than 99.5%, zinc ingots with a purity greater than 99.5%, and Al-Ti-B fines according to the composition of the elements. Chemical agent is used as raw material, and the raw material is dried at 100°C;

[0028] 2) Melting: first use the well-type crucible resistance furnace to melt the pure aluminum ingot, when the temperature of the pure aluminum liquid reaches 900 ℃, then add the Al-Si master alloy, after the Al-Si master alloy is c...

Embodiment 2

[0032] A cast aluminum-silicon alloy with high thermal conductivity, composed of the following elements by weight percentage: Si: 3.9%, Cu: 0.3%, Mg: 0.38%, Zn: 0.04%, Ti: 0.12%, B: 0.12%, others The total sum of impurities is not more than 0.02%, and the balance is Al.

[0033] The preparation method of the cast aluminum-silicon alloy with high thermal conductivity comprises the following steps:

[0034] 1) Drying: Select pure aluminum ingots with a purity greater than 99.5%, Al-Si master alloys, Al-Cu master alloys, magnesium ingots with a purity greater than 99.5%, zinc ingots with a purity greater than 99.5%, and Al-Ti-B fines according to the composition of the elements. Chemical agent is used as raw material, and the raw material is dried at 100°C;

[0035] 2) Melting: first use the well-type crucible resistance furnace to melt the pure aluminum ingot, when the temperature of the pure aluminum liquid reaches 850°C, then add the Al-Si master alloy, and then add the Al-Si...

Embodiment 3

[0039] A cast aluminum-silicon alloy with high thermal conductivity, composed of the following elements by weight percentage: Si: 5.5%, Cu: 0.4%, Mg: 0.70%, Zn: 0.1%, Ti: 0.2%, B: 0.05%, others The total sum of impurities is not more than 0.02%, and the balance is Al.

[0040] The preparation method of the cast aluminum-silicon alloy with high thermal conductivity comprises the following steps:

[0041] 1) Drying: Select pure aluminum ingots with a purity greater than 99.5%, Al-Si master alloys, Al-Cu master alloys, magnesium ingots with a purity greater than 99.5%, zinc ingots with a purity greater than 99.5%, and Al-Ti-B fines according to the composition of the elements. Chemical agent is used as raw material, and the raw material is dried at 100°C;

[0042] 2) Melting: first use the well-type crucible resistance furnace to melt the pure aluminum ingot, when the temperature of the pure aluminum liquid reaches 880 ℃, then add the Al-Si master alloy, after the Al-Si master a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com