Bleaching reagent as well as preparation method and application thereof, and application of peracetic acid A liquid

A technology of peracetic acid and reagents, applied in the field of bleaching reagents and its preparation, and peracetic acid A solution, which can solve the problems of poor bleaching effect and hair damage, and achieve the effects of less hair damage, less pollution, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

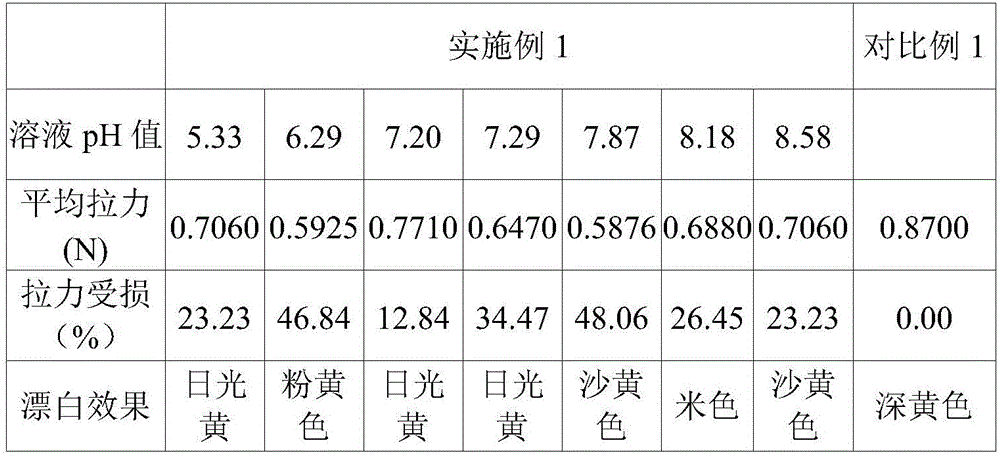

[0047] Dilute Peracetic Acid Solution A with 4 times of water, take 40ml of Peracetic Acid Solution A dilution in a beaker, put it in a 60°C constant temperature water bath to heat, add 0.096g of sodium pyrophosphate to the solution, mix well, and use anhydrous Calcium carbonate adjusts the pH, yielding a bleaching agent. Add a little dyed hair as it is into a beaker, add 60°C bleaching reagent until it is covered with the original hair, and bleach at a constant temperature of 60°C. When the hair bleaching time is 80 minutes, the reaction ends, take out the hair, and rinse with excess distilled water. The bleaching agent on the surface of the hair is removed. The effect of different pH values on the hair bleaching effect is shown in Table 1.

Embodiment 2

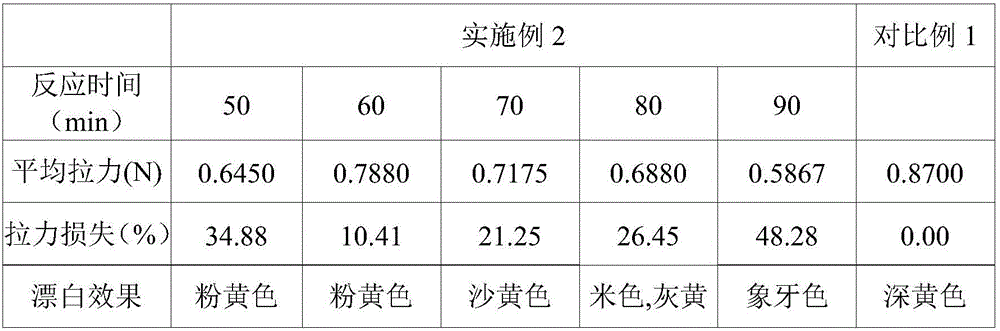

[0054] Dilute Peracetic Acid Solution A with 4 times of water, take 40ml of Peracetic Acid Solution A dilution in a beaker, put it in a 60°C constant temperature water bath to heat, add 0.096g of sodium pyrophosphate to the solution, mix well, and use anhydrous Calcium carbonate adjusts the pH to 8.18 to obtain a bleaching reagent. Put a little dyed hair into the beaker and add 60°C bleaching agent until the original hair is covered. Bleaching is carried out at a constant temperature of 60°C, and different reaction times are adjusted. After the reaction, the hair is taken out and rinsed with excess distilled water. The bleaching agent on the surface of the hair is removed. The effects of different reaction times on the hair bleaching effect are shown in Table 2.

[0055] Table 2

[0056]

[0057] It can be seen from Table 2 that as the temperature increases, the hair bleaching effect becomes better, but the hair strength decreases. Considering the actual application situa...

Embodiment 3

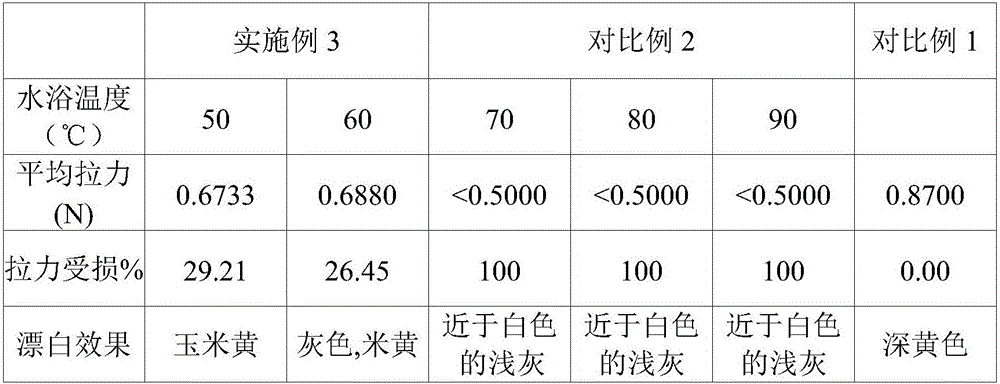

[0059]Dilute peracetic acid solution A with 4 times of water, take 40ml of peracetic acid solution A in a beaker, put it in a constant temperature water bath at different temperatures to heat, add 0.096g of sodium pyrophosphate to the solution, mix well, and use anhydrous calcium carbonate Adjust the pH value to 8.18 to obtain a bleaching reagent. Add a little dyed hair as it is into the beaker, add the bleaching agent obtained in the constant temperature water bath to the original hair, and continue to bleach under constant temperature conditions. When the hair bleaching time is 80min, the reaction is over, the hair is taken out, and the excess Rinse with distilled water to remove bleach from the surface of the hair. See Table 3 for the effects of different water bath temperatures on the hair bleaching effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com