Water well structure for foundation pit dewatering and construction method thereof

A technology for water well construction and water wells, which is applied in basic structure engineering, construction and other directions, can solve the problems of long construction period, inconvenient construction, and affect the safety of adjacent buildings, and achieves the effect of simple and practical construction method and short period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

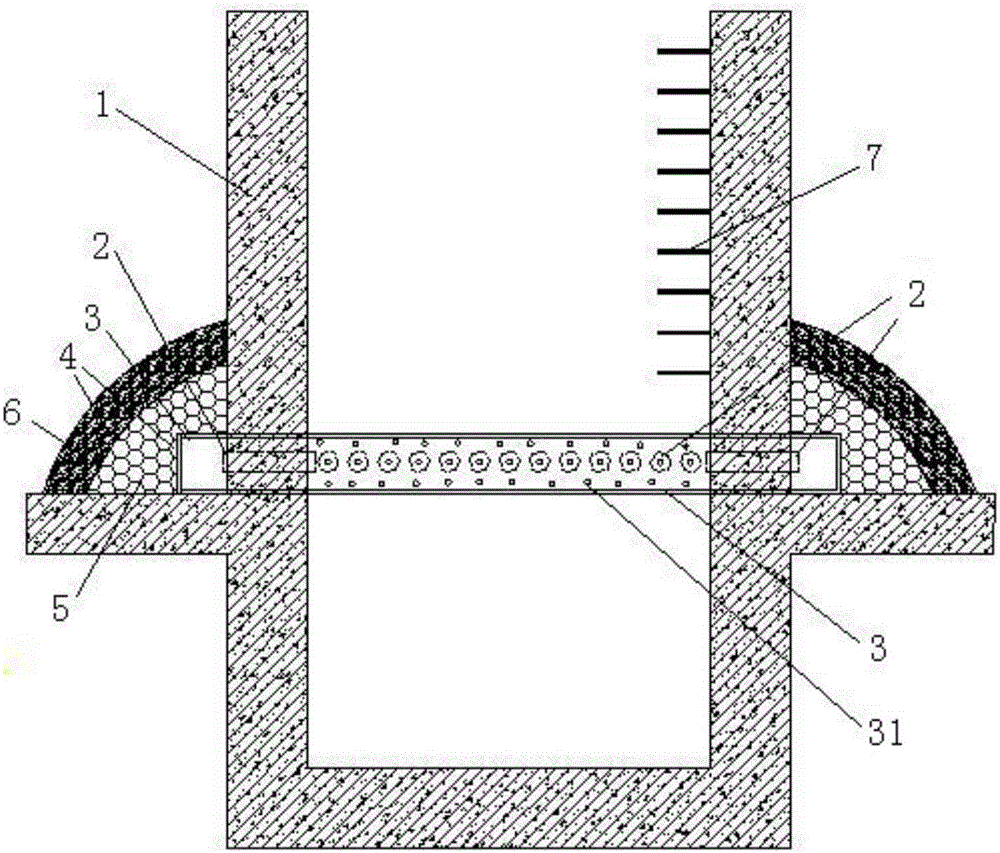

[0026] Refer to attached figure 1 , the present embodiment provides a foundation pit dewatering well structure, including a water well 1, the water well 1 is a square well structure, and the position distribution of 1m above the elevation of the bottom plate of the water well is installed with a water-passing steel casing 2 with a diameter of 100mm at a spacing of 150mm, and a water-passing steel The casing 2 runs through the side wall of the water well, and the outside of the water well 1 is installed and fixed with a permeable steel plate 3 through steel bars. The outer side of the water-passing steel casing 2, and the closed structure between the permeable steel plate 3 and the outer wall of the well 1, the type of channel steel used for the permeable steel plate 3 is 14b, that is, the height is 140mm, the leg width is 60mm, and the waist thickness is 8mm. The outer side of 3 lays geotextile 4, cobblestone 5, geotextile 4 and crushed stone filter layer 6 successively, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thick waist | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com