Coating-tube-binder steel-tube-recycled-concrete-column and steel-girder connecting joint and construction method

A technology for reclaiming concrete and connecting nodes, which is applied to buildings and building structures, etc., can solve the problems of difficult coordination of performance, construction and cost, insufficient quantitative research and analysis, and few forms of nodes, and is conducive to energy conservation, environmental protection and safety. Sustainable utilization of resources, meeting design requirements, economical and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

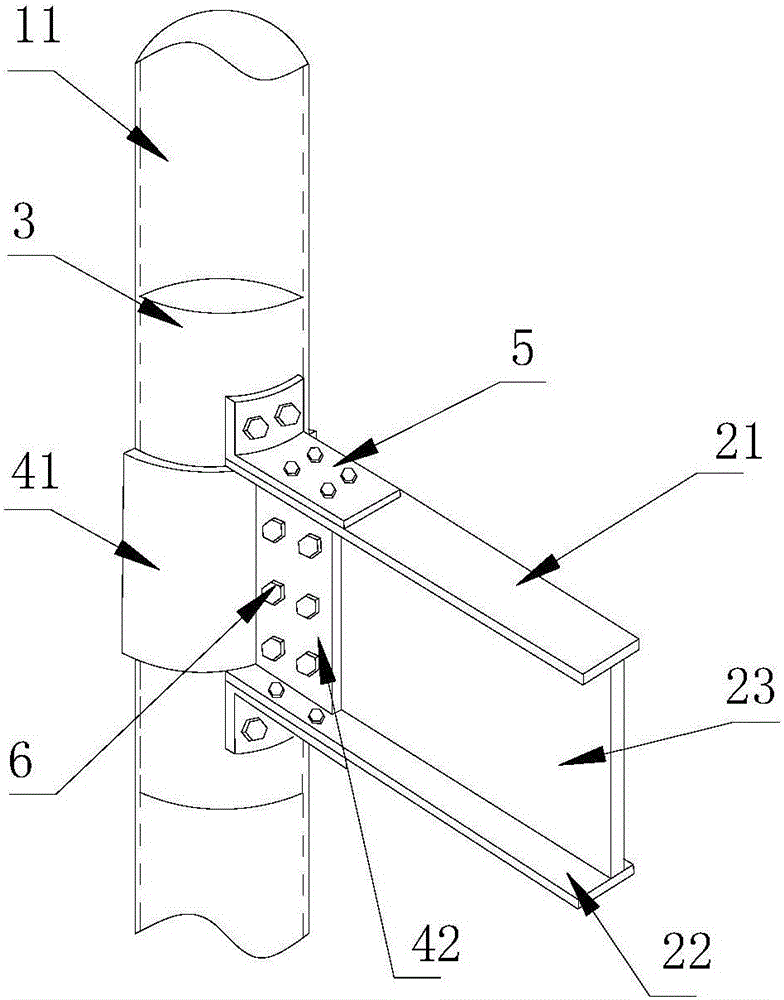

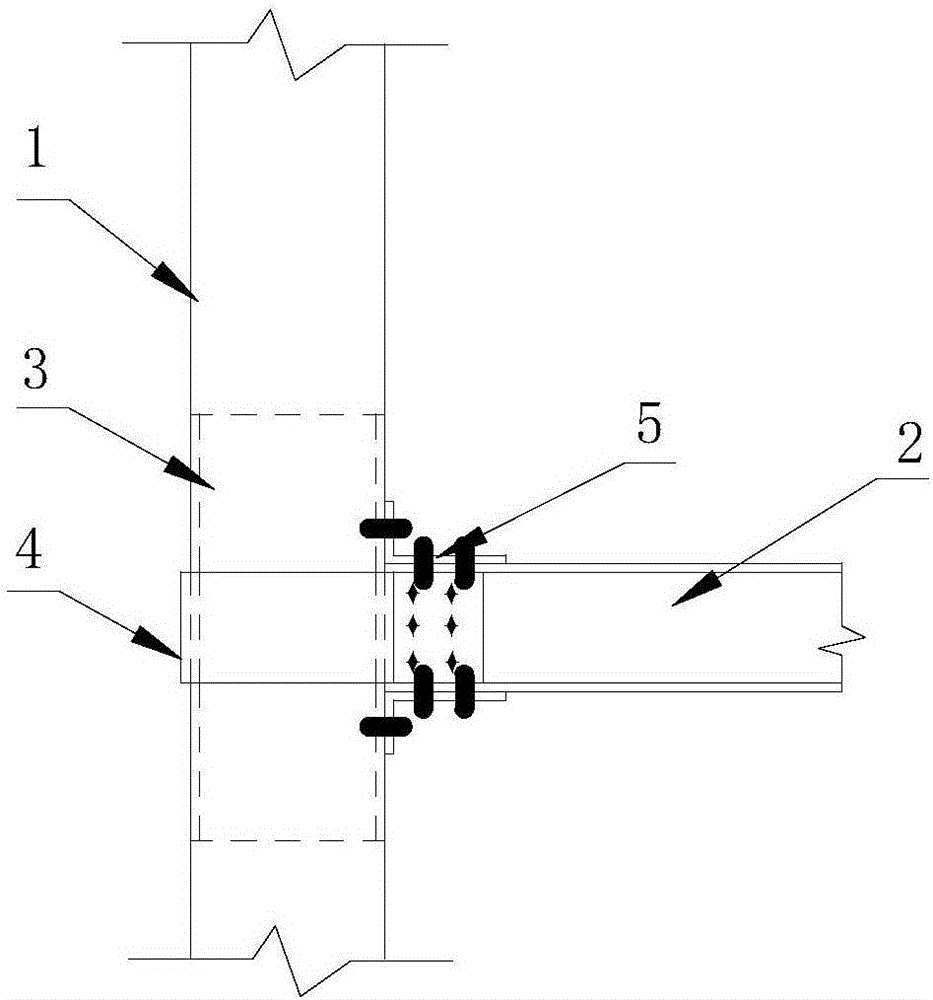

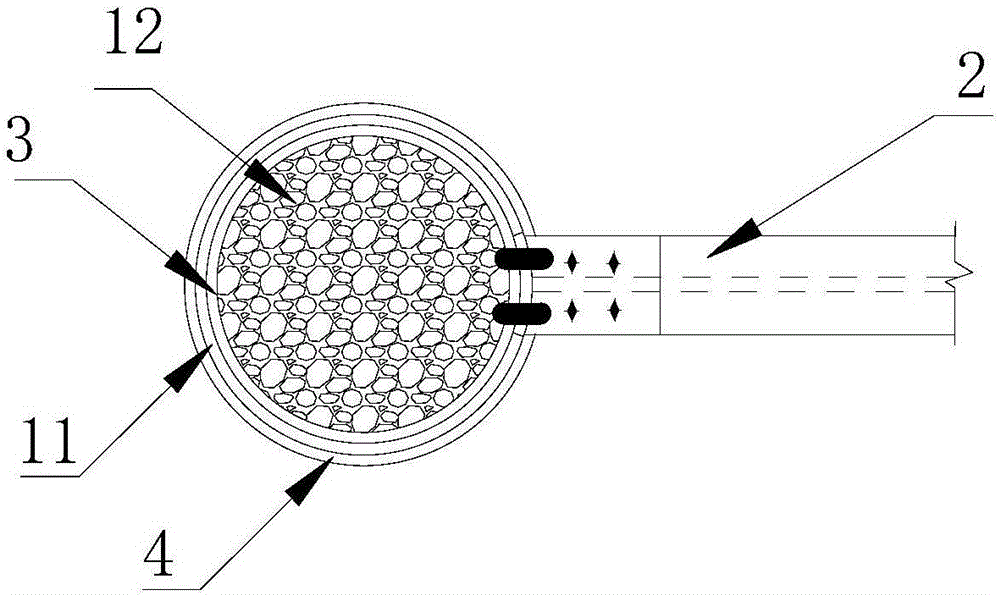

[0035] Such as Figure 1-3 As shown in the figure, the connection node between the steel tube recycled concrete column and the steel beam includes a steel tube recycled concrete column 1, a steel beam 2, a built-in steel tube 3, a jacket clamp tube 4 and an angle steel 5. The steel pipe recycled concrete column includes an outsourcing steel pipe 11 and recycled concrete 12 , and the recycled concrete 12 is filled in the outsourcing steel pipe 11 . The intersection of the steel pipe recycled concrete column 1 and the steel beam 2 forms a node domain, and the built-in steel pipe 3 is located in the outsourcing steel pipe 11 at the node domain. The built-in steel pipe 3 extends upward and downward for a certain length from the upper edge and the lower edge of the node domain respectively, and the extension part is tightly connected with the outsourcing steel pipe 11 and the angle steel 5 .

[0036] Steel pipe recycled concrete column 1 and steel beam 2 are fastened and connected...

Embodiment 2

[0046] Such as Figure 4-5As shown in the figure, the connection node between the steel pipe recycled concrete column and the steel beam with jacket pinched tube includes recycled steel tube concrete column 1, two steel beams 2, built-in steel pipe 3, two jacket pinched tubes 4 and angle steel 5. The steel pipe recycled concrete column includes an outsourcing steel pipe 11 and recycled concrete 12 , and the recycled concrete 12 is filled in the outsourcing steel pipe 11 . The two steel beams 2 are arranged oppositely on the recycled steel pipe concrete column 1, the intersection of the steel pipe recycled concrete column 1 and the steel beam 2 forms a node domain, and the built-in steel pipe 3 is located in the outer steel pipe 11 at the node domain. The built-in steel pipe 3 extends upward and downward for a certain length from the upper edge and the lower edge of the node domain respectively, and the extension part is tightly connected with the outsourcing steel pipe 11 and ...

Embodiment 3

[0057] The connection node and construction method of the jacket-clamped steel pipe recycled concrete column and the steel beam in this embodiment are basically the same as in Embodiment 1, the difference is that the outsourcing steel pipe and the built-in steel pipe are all square steel pipes, and the jacket clamping pipe The annular part is also a quadrangle with an opening, which matches the size and shape of the outsourcing steel pipe. In addition, the shape of the angle steel and the end of the steel beam also matches the size and shape of the outsourcing steel pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com