A Buckling Induced Brace with Oblique Helical Induced Units at the End

A helical, oblique technology, applied in building types, buildings, building components, etc., can solve problems such as unfavorable plastic hinges, low design flexibility, etc., to simplify the manufacturing process, flexible layout, good energy consumption and Effect of axial load carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

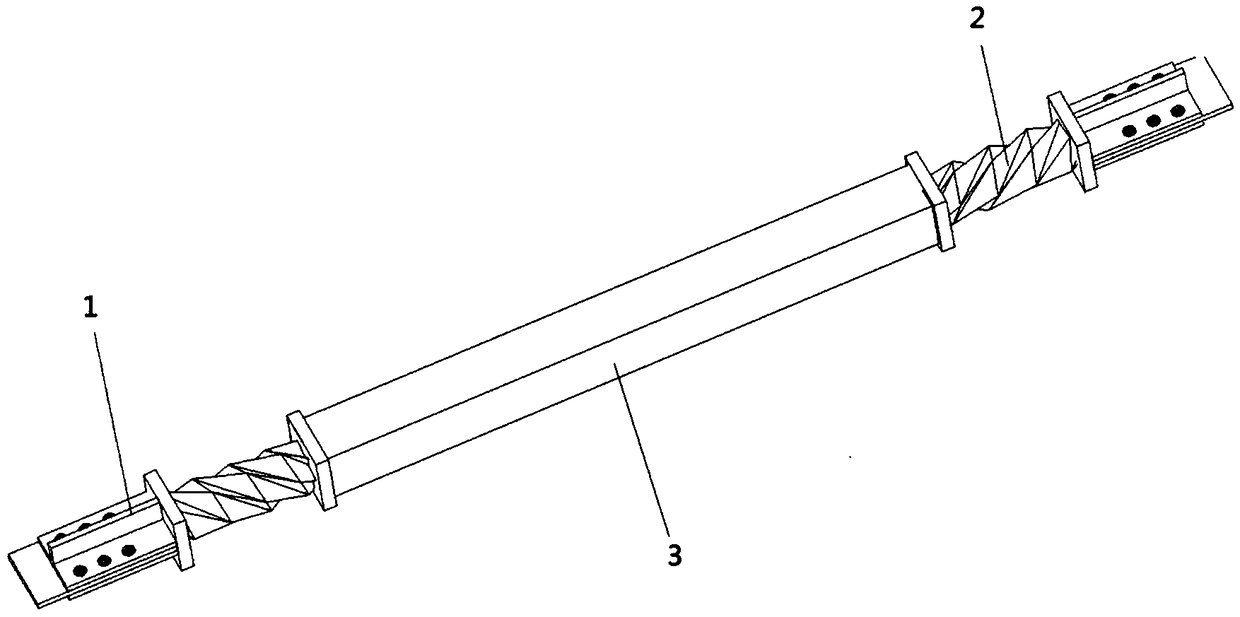

[0026] figure 1 It is a structural schematic diagram of a buckling-induced brace with oblique helical induction elements at the end, which is composed of end restraint section 1, energy dissipation section 2 and brace straight section 3, and end restraint section 1 is fixed at the beam-column node and the energy dissipation section Between the sections 2, the energy dissipation section 2 is fixed at both ends of the supporting straight section 3.

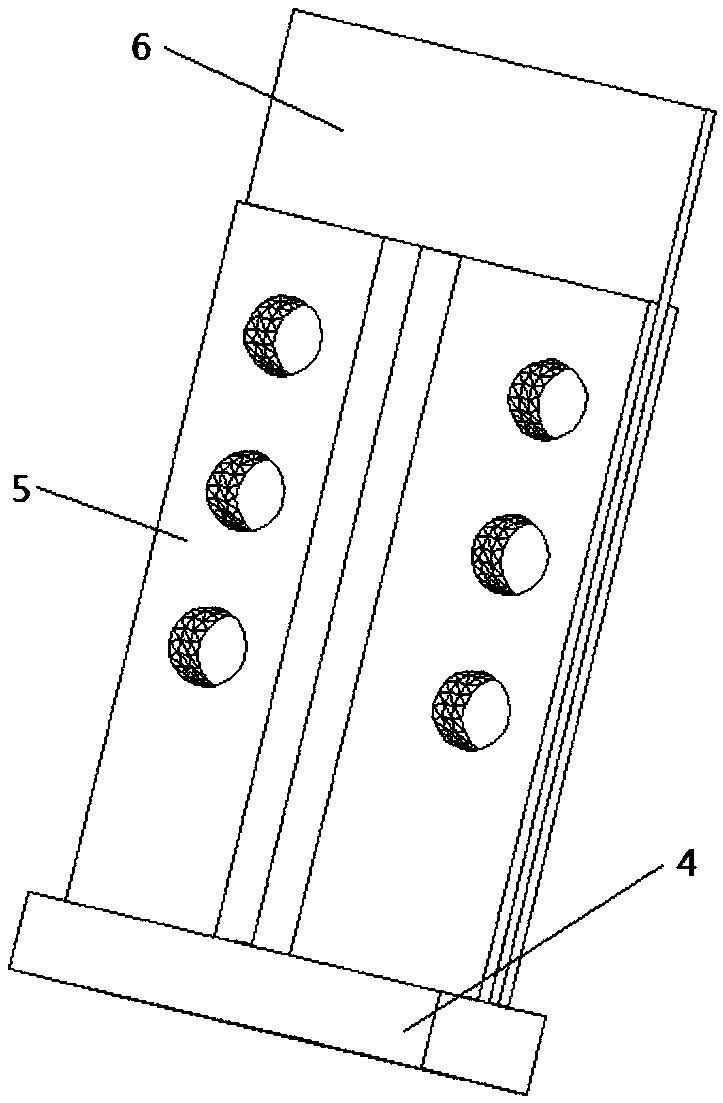

[0027] Such as figure 2 As shown, the end restraint section 1 is composed of a square steel plate 4, a T-shaped short steel beam 5, and a connecting plate 6 reserved for components such as beams and columns. The square steel plate 4 is welded to the end of the energy dissipation section 2. Two T-shaped short steel The beam 5 is welded to the square steel plate 4, and the square steel plate 4 and the T-shaped short steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com