Processing method for extremely-high geostress soft rock tunnel arch wall lining cracking damage

A treatment method and ground stress technology, applied in the field of tunnel disease control, can solve problems such as threats to construction safety, insufficient lining thickness, large deformation of surrounding rock, etc., and achieve the effect of controlling deformation of tunnel surrounding rock, compact construction process and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

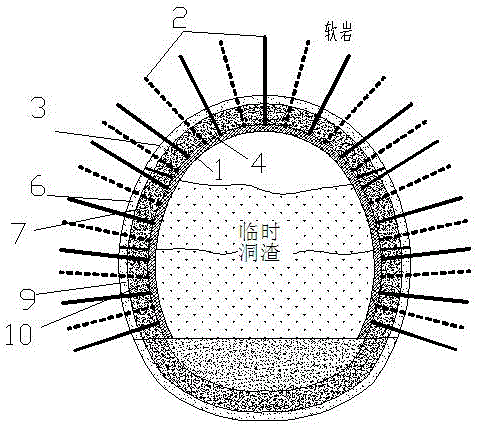

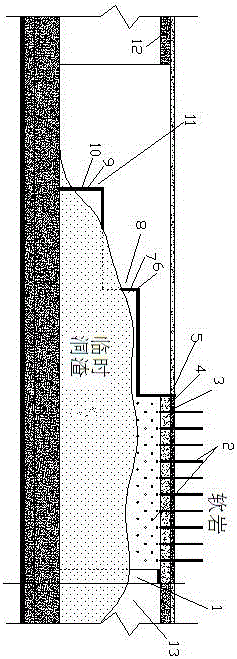

[0033] combined with figure 1 and 2 Implement the processing method of the cracking and damage of the very high ground stress soft rock tunnel lining of the present invention, and the described method can be used when dealing with the cracking damage of the very high ground stress soft rock tunnel lining, and the steps of the method are as follows:

[0034] (1) When dealing with the cracking and damage of the lining structure of soft rock tunnels with extremely high geostress, first determine the demolition section, and apply a reinforcement layer 1 at the junction of the lining demolition and non-demolition sections, and the width of the reinforcement layer is 1m;

[0035] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com