One-way valve device used for oil receiving through series-wound hydrodynamic retarder

A hydraulic retarder and one-way valve technology, applied in the field of auto parts, can solve problems such as medium oil loss and environmental pollution, and achieve the effects of slowing down the frequency of refueling, reducing evaporation, and reducing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed below, and detailed descriptions are as follows in conjunction with the accompanying drawings.

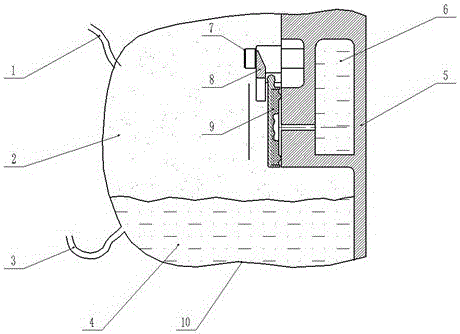

[0012] Combine below figure 1 The structure of the oil collection one-way valve device for series hydraulic retarder of the present invention is described in detail. A one-way valve device for oil collection of a hydraulic retarder in series, comprising an oil seal cover pressure plate 8 and an oil storage chamber 10, the oil seal cover pressure plate 8 is equipped with a bolt 7, and the bolt 7 connects the oil seal cover pressure plate 8 and the oil storage chamber 10 The retarder cover 5 is connected together, the retarder cover 5 is equipped with an oil sealing cover assembly 9, the inner side of the oil sealing cover assembly 9 is equipped with a vulcanized rubber surface 11, and the oil storage chamber 10 is located in the over...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap