A kind of slagging device and garbage incinerator

A technology of slag removal and cohesion, which is applied to incinerators, combustion types, combustion methods, etc., can solve problems such as optimization research, and achieve the effects of improving strength and stability, smooth slagging, and releasing thermal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

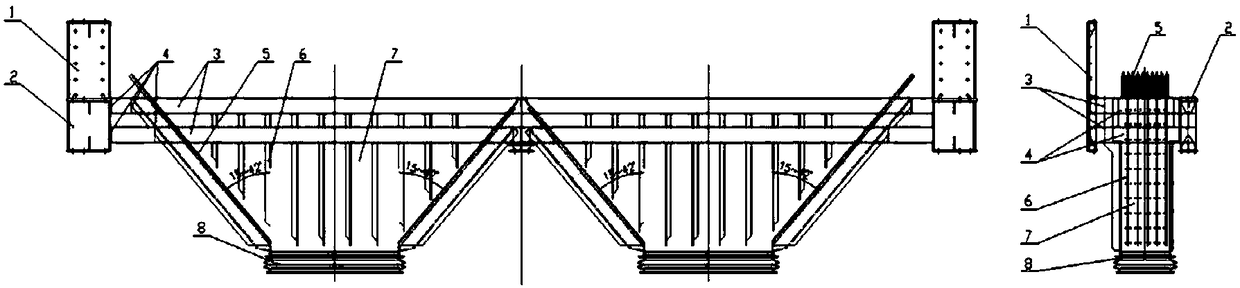

[0028] Refer below figure 1 To illustrate the slagging device of the present invention.

[0029] Such as figure 1 As shown, a slag discharge device includes at least two pairs of long structural columns 1 and short structural columns 2 oppositely arranged, and between the long structural columns 1 and the short structural columns 2 passes H-shaped steel 3 and channel steel group 4 are connected to form the main frame structure, wherein the long structural column 1, the short structural column 2, the H-shaped steel 3 and the channel steel group 4 are all shaped steel.

[0030] This type of structure is composed of well-stressed section steel, which can ensure the main strength, rigidity, thermal expansion and thermal deformation of the slag discharge device.

[0031] Specifically, there are at least four channel steel groups 4, which are spaced up and down on the at least two pairs of long structural columns 1 and short structural columns 2 that are oppositely arranged.

[0...

Embodiment 2

[0045] The invention discloses a garbage incinerator, which comprises the above-mentioned slagging device. The garbage incinerator can improve the strength and stability of the overall structure, effectively release thermal stress, facilitate on-site installation, and make slag discharge more smoothly.

[0046] A large number of high-strength section steels are used as the main frame structure of the slag discharge device, which can improve the strength and stability of the overall structure; the use of light rail components and ribbed plate structures, and the filling of refractory materials can further improve the strength and stability; the use of expansion joints It can effectively release thermal stress; through bolt connection and expansion joint adjustment, it is beneficial to on-site installation; scientific slag discharge angle can make slag discharge more smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com