Wood drying chamber with flow guiding device

A technology of wood drying and diversion device, which is applied in the direction of wood drying, static material dryer, drying gas arrangement, etc. It can solve problems such as cracking and uneven drying, achieve uniform distribution, avoid severe local heating, and accelerate circulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

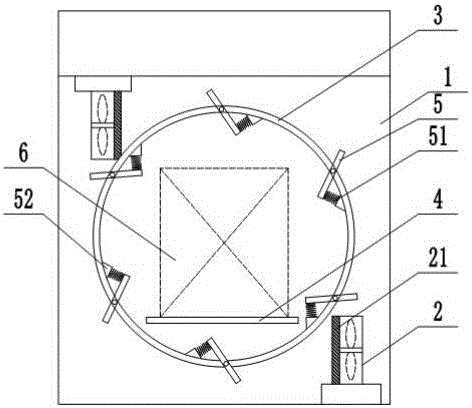

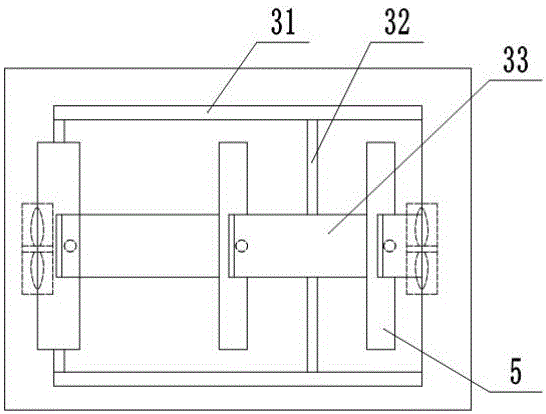

[0016] The reference signs in the drawings of the description include: box body 1, hot air blower 2, protective cover 21, flow guide frame 3, outer frame 31, connecting rod 32, installation ring 33, support plate 4, deflector plate 5, spring 51 , installation block 52, timber 6.

[0017] The embodiment is basically as attached figure 1 and figure 2 Shown:

[0018] A wood drying room with flow guide device, mainly composed of a box body 1, a hot air blower 2 and a support plate 4 for preventing wood 6, and also includes a flow guide frame 3, which is rotatably connected in the box body 1 , the deflector 5 is circular, and the deflector frame 3 includes two circular outer frames 31 and some connecting rods 32 connecting the two outer frames 31 together. Arranged mounting ring 33. Through the arrangement of the outer frame 31, the connecting rod 32 and the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com