Multistage liquid-separation plate-type condenser

A condenser and liquid plate technology, applied in the field of multi-stage liquid-separating plate condensers, can solve problems such as reduction and accumulation, and achieve the effects of strengthening condensation heat transfer, good economy, and reducing condensation heat transfer thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

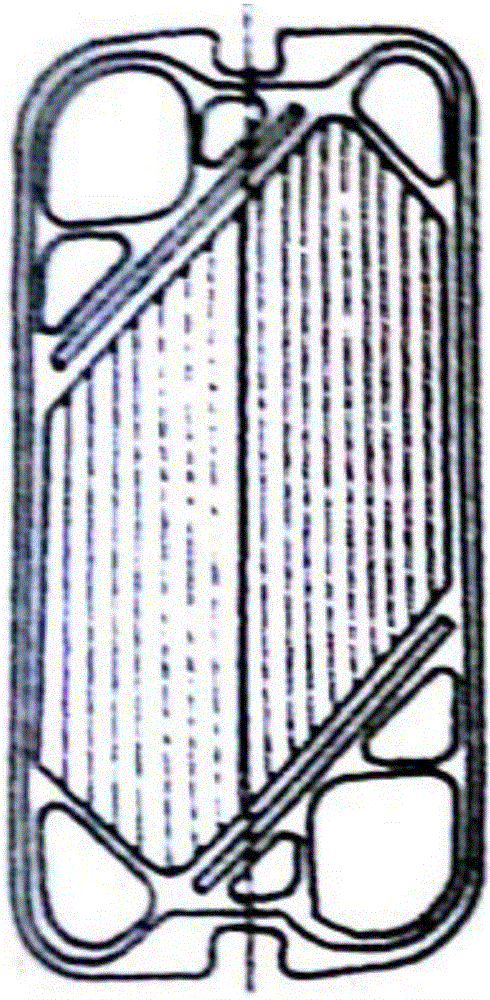

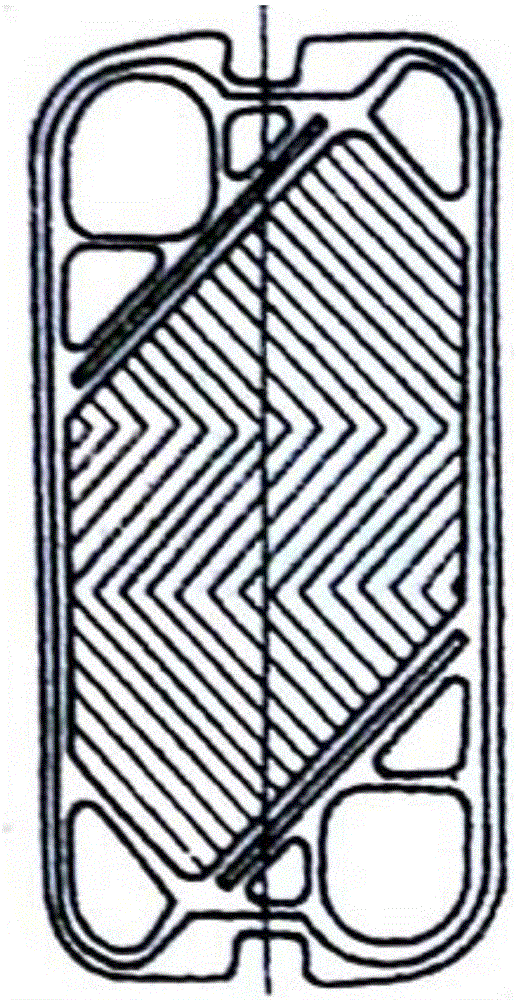

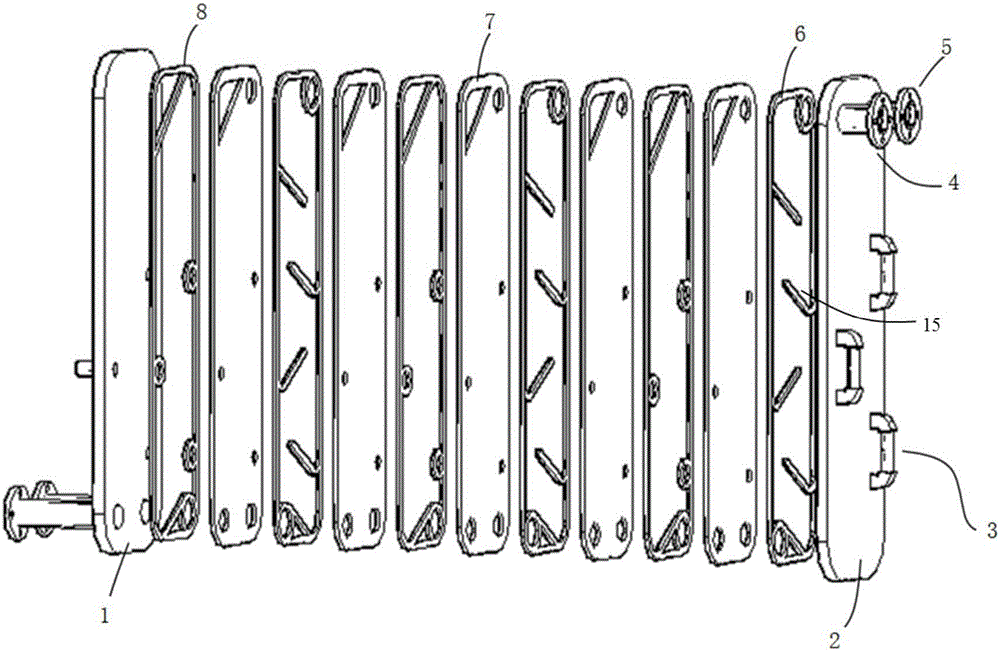

[0042] A multi-stage separatory plate condenser, such as Figure 2-11 As shown, it includes a front end cover plate 2, a rear end cover plate 1, at least one heat exchange plate 7, at least one water side gasket 8 and at least one steam side gasket 6, the water side gasket 8 and the steam side seal Pads 6 are respectively located on both sides of the heat exchange plate 7 to form a steam flow channel and a cooling water flow channel. The heat exchange plate 4 is provided with a steam inlet corner hole 65, a liquid separation corner hole for the first to nth (n is a natural number greater than 1) stage condensate, a cooling water inlet corner hole, a cooling water outlet corner hole and The liquid separation angle hole 64 of the final stage condensate, wherein the liquid separation angle hole is used to drain the condensate out of the condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com