Indoor gyratory compaction test method for MOH semi-flexible materials

A test method and rotary compaction technology, which is applied in the field of materials, can solve problems such as lack, and achieve the effect of high compactness, simple process steps, and small changes in compactness values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

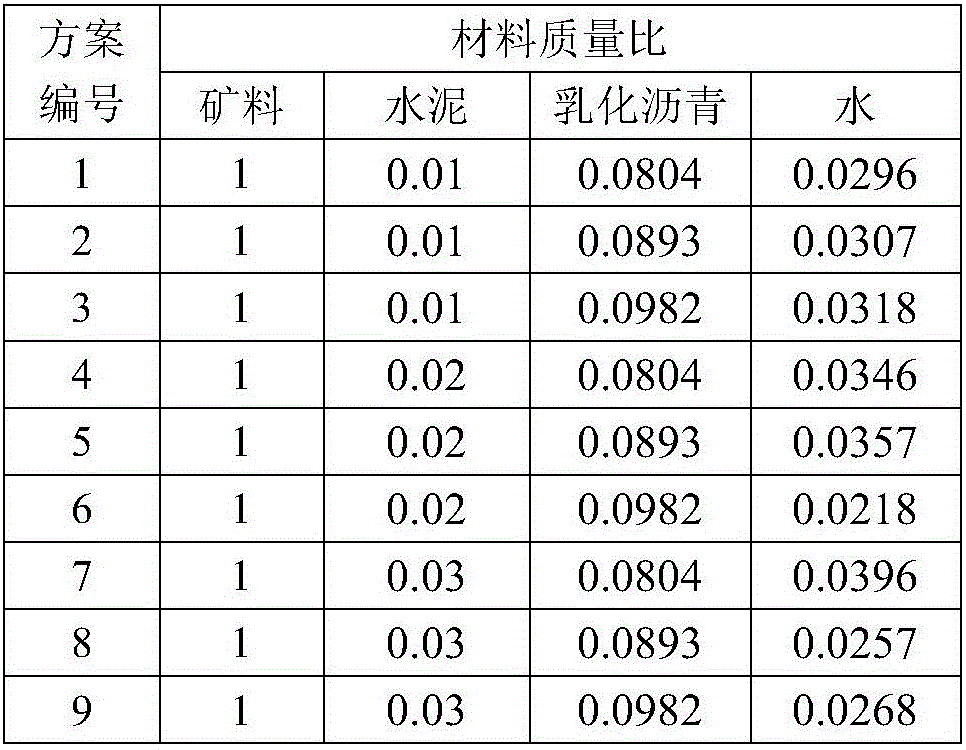

Embodiment 1

[0053]Step 1. According to the mass ratio, mix the mineral material: cement: water: emulsified asphalt according to 1:0.01:0.0296:0.0804. First, mix the mineral material and cement evenly, inject water to make the surface of the mineral material wet, and then add emulsified asphalt and stir. Stir the mixture until it begins to demulsify, and make the temperature of the mixed mixture 25°C to make a MOH mixture;

[0054] Step 2: Put the lower pressure plate of the test mold into the bottom of the test mold, place a round filter paper coated with butter on the surface of the lower pressure plate, shovel the MOH mixture into the test mold with small holes, and insert it along the periphery with a slotting knife. Pounding 15 times, inserting and pounding 10 times in the middle, after inserting and pounding, level the surface of the MOH mixture into a circular arc surface, then place a circular filter paper coated with butter on the top of the mixture, and finally place the upper pla...

Embodiment 2

[0058] Step 1. According to the mass ratio, mix the mineral material: cement: water: emulsified asphalt according to 1:0.03:0.0268:0.0982. First, mix the mineral material and cement evenly, inject water to make the surface of the mineral material wet, and then add emulsified asphalt and stir. Stir the mixture until it begins to demulsify, and make the temperature of the mixed mixture 25°C to make a MOH mixture;

[0059] Step 2: Put the lower pressure plate of the test mold into the bottom of the test mold, place a round filter paper coated with butter on the surface of the lower pressure plate, shovel the MOH mixture into the test mold with small holes, and insert it along the periphery with a slotting knife. Pounding 15 times, inserting and pounding 10 times in the middle, after inserting and pounding, level the surface of the MOH mixture into a circular arc surface, then place a circular filter paper coated with butter on the top of the mixture, and finally place the upper pl...

Embodiment 3

[0063] Step 1. According to the mass ratio, mix the mineral material: cement: water: emulsified asphalt according to 1:0.02:0.0357:0.0893. First, mix the mineral material and cement evenly, inject water to make the surface of the mineral material wet, and then add the emulsified asphalt and stir. Stir the mixture until it begins to demulsify, and make the temperature of the mixed mixture 25°C to make a MOH mixture;

[0064] Step 2: Put the lower pressure plate of the test mold into the bottom of the test mold, place a round filter paper coated with butter on the surface of the lower pressure plate, shovel the MOH mixture into the test mold with small holes, and insert it along the periphery with a slotting knife. Pounding 15 times, inserting and pounding 10 times in the middle, after inserting and pounding, level the surface of the MOH mixture into a circular arc surface, then place a circular filter paper coated with butter on the top of the mixture, and finally place the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com