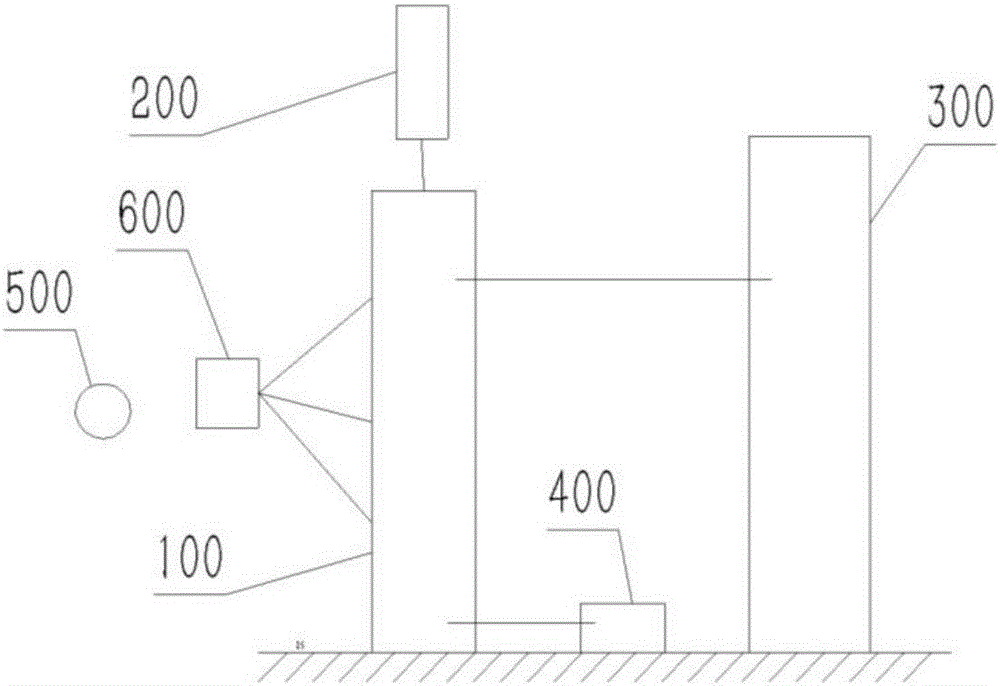

Loadable permeability test device

A permeation device and permeameter technology, applied in the field of geotechnical engineering, can solve problems such as soil compression deformation, soil permeability change, pore change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

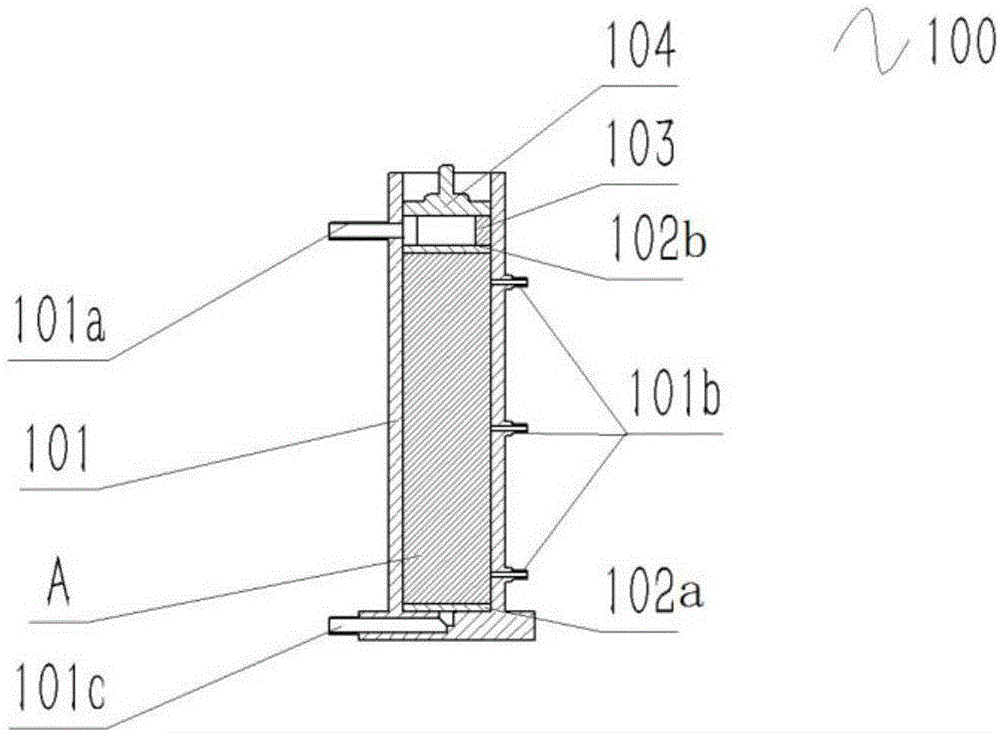

Method used

Image

Examples

specific Embodiment approach

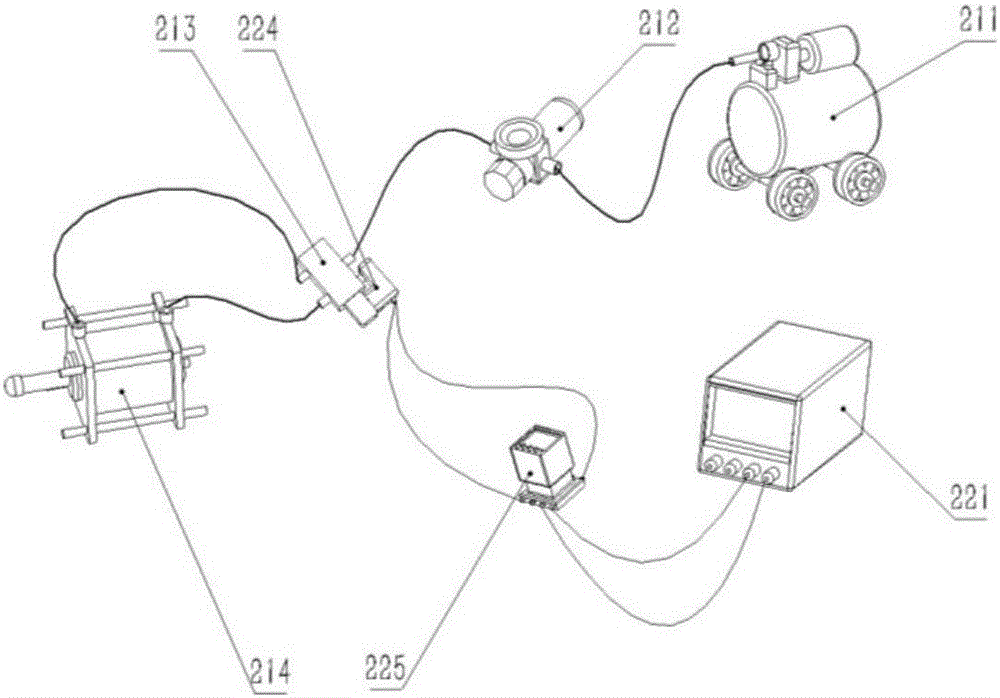

[0051] The specific implementation is as follows: the air pressure system 210 provides a power source, which is applied to the permeable stone 102 and the sample through the loading cover 104 and the ring with holes 103 in sequence. The pneumatic circuit control system controls the loading method, application size and application time. Impact load, constant static pressure load and cyclic static pressure load can be applied to the sample through three air circuit connection methods: impact load connection mode, constant pressure static pressure load connection mode and cyclic static pressure load connection mode.

[0052] Wherein, when the load of the vertical load loading module 200 is an impact dynamic load, such as image 3 The specific structure shown is: including a DC power supply 221 connected in sequence, a time relay 225 and a solenoid valve 224 connected in sequence in a circuit; 214 , the solenoid valve 224 is installed on the cylinder switch 213 for controlling th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com