Experimental device and method for measuring pipe wall stress and frictional resistance coefficients

A technology of frictional resistance and experimental equipment, applied in the direction of measuring equipment, mechanical equipment, force/torque/power measuring instrument, etc., can solve the problems of failure to realize vertical pipeline measurement, failure to consider pipeline stress measurement, etc., and achieve The effect of protecting pipelines and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

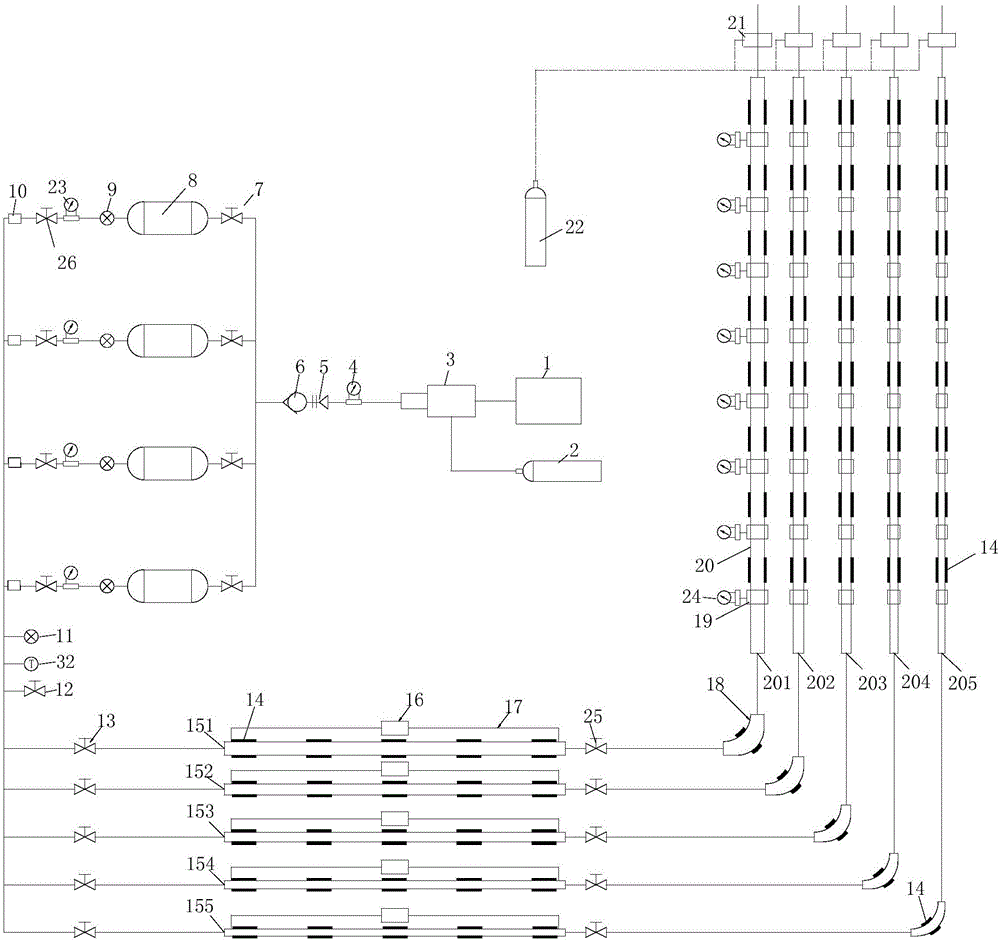

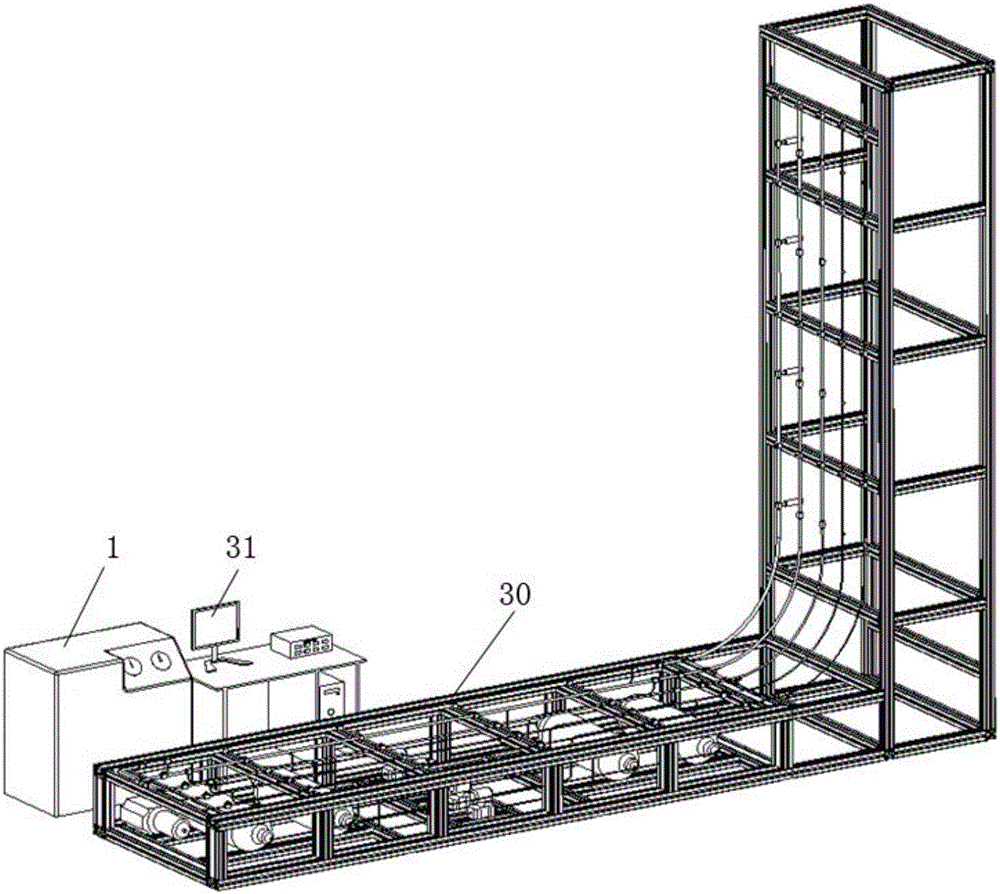

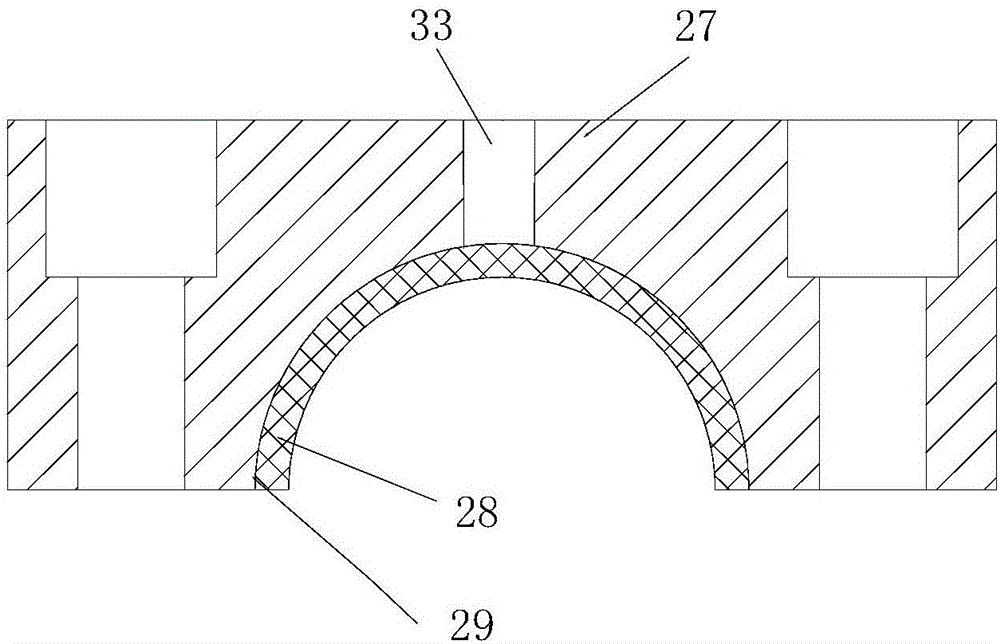

[0043] Such as Figure 1 to Figure 3 As shown, an experimental device for measuring pipe wall stress and frictional resistance coefficient, including air compressor 1, dryer, filter, first gas cylinder 2, booster pump 3, No. 3 pressure transmitter 4, safety valve 5. One-way valve 6, four gas storage branches, five high-pressure horizontal pipelines, multiple biaxial strain rosettes 14, five differential pressure sensors 16, five pressure introduction pipelines 17, strain gauges, data acquisition modules, and computers 31 , five bent pipes 18, five high-pressure vertical pipelines, the second gas cylinder 22 and five large flow back pressure devices 21.

[0044] The booster pump 3 is connected to the air compressor 1 and the first gas cylinder 2 respectively, and both the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com