Heating plate impedance measuring tool and heating plate impedance measuring method

A technology of impedance measurement and heating plate, which is applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of weak signal and large error of measurement data, and achieve reasonable structure, tight contact and improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

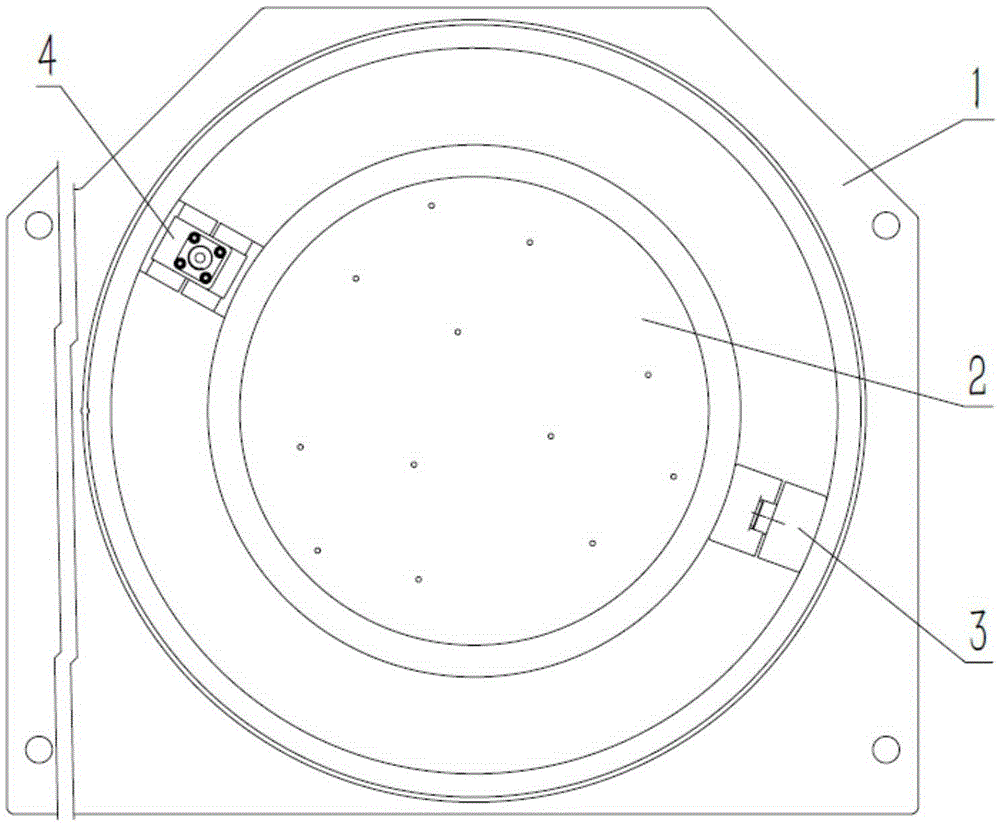

[0023] Refer to attached Figure 1-5 , heating plate impedance measurement tool, mainly by the insulation assembly 3 and the electrode assembly 4 two parts.

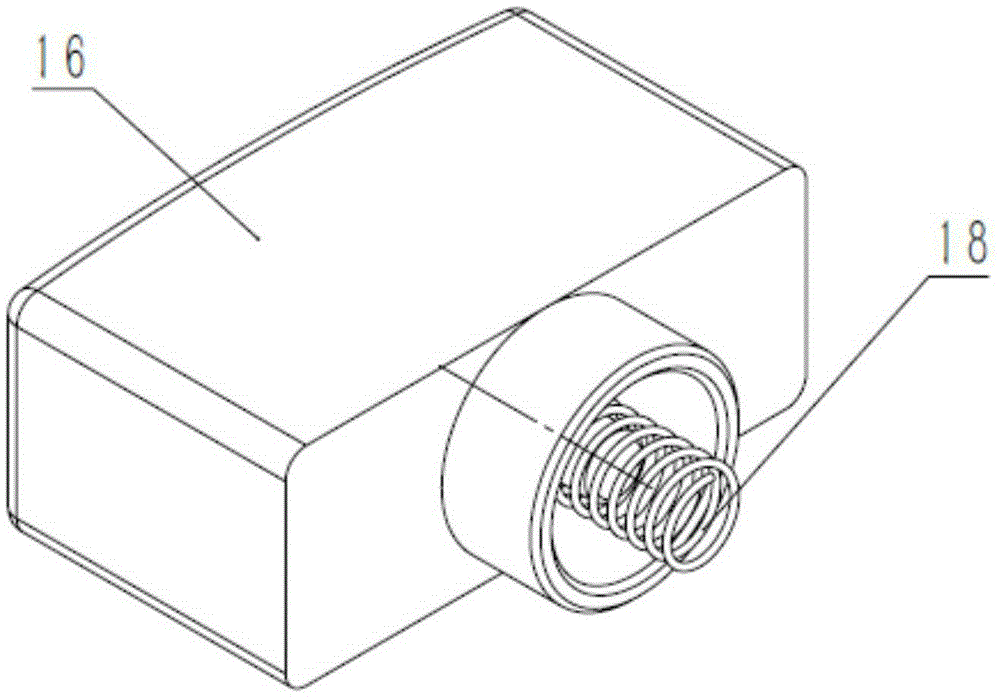

[0024] The insulating assembly 3 includes an insulating block A16, an insulating block B17 and a spring 18, and a spring 18 is installed between the insulating block A16 and B17 to form a compressible pre-tightening force against the force from the electrode assembly 4 during the impedance measurement of the heating plate 2, Ensure that the heating plate is evenly stressed and its position is centered.

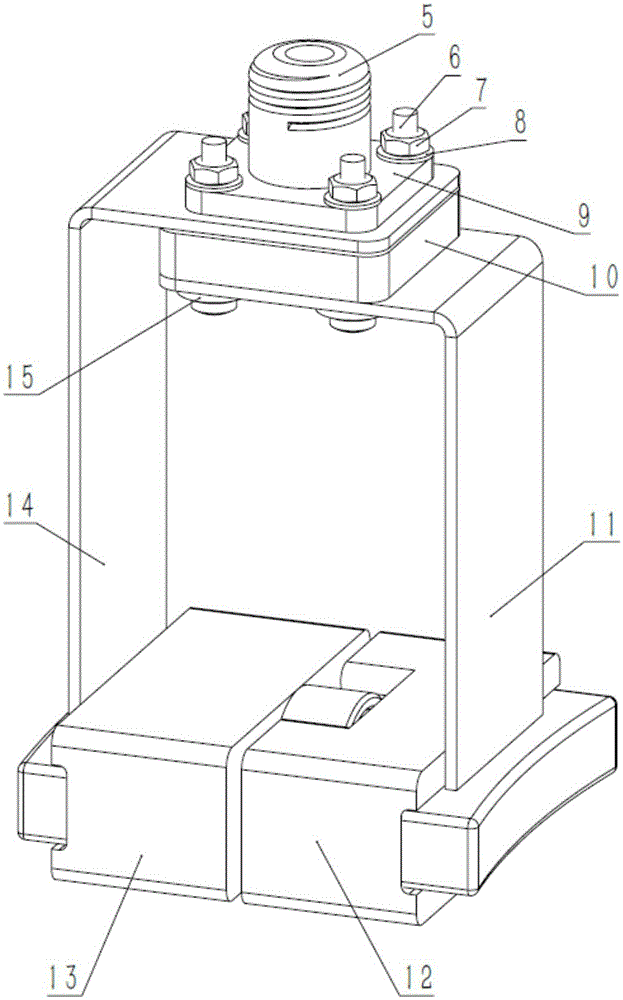

[0025] The electrode assembly 4 includes an N connector socket positioning base 5, a fixing screw 6, a nut 7, a gasket 8, a connecting plate 9, an insulating plate 10, an electrode plate A11, an insulating seat A12, an insulating seat B13, and an electrode plate B14 , insulating sleeve 15 and spring 18.

[0026] The positioning base 5 of the N connector socket is fixedly connected to the electrode plate B14 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com