Lead acid battery service life prediction method

A lead-acid battery, life prediction technology, applied in the direction of lead-acid batteries, measuring electricity, measuring devices, etc., can solve problems such as life and production safety hazards, and achieve the effect of easy operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

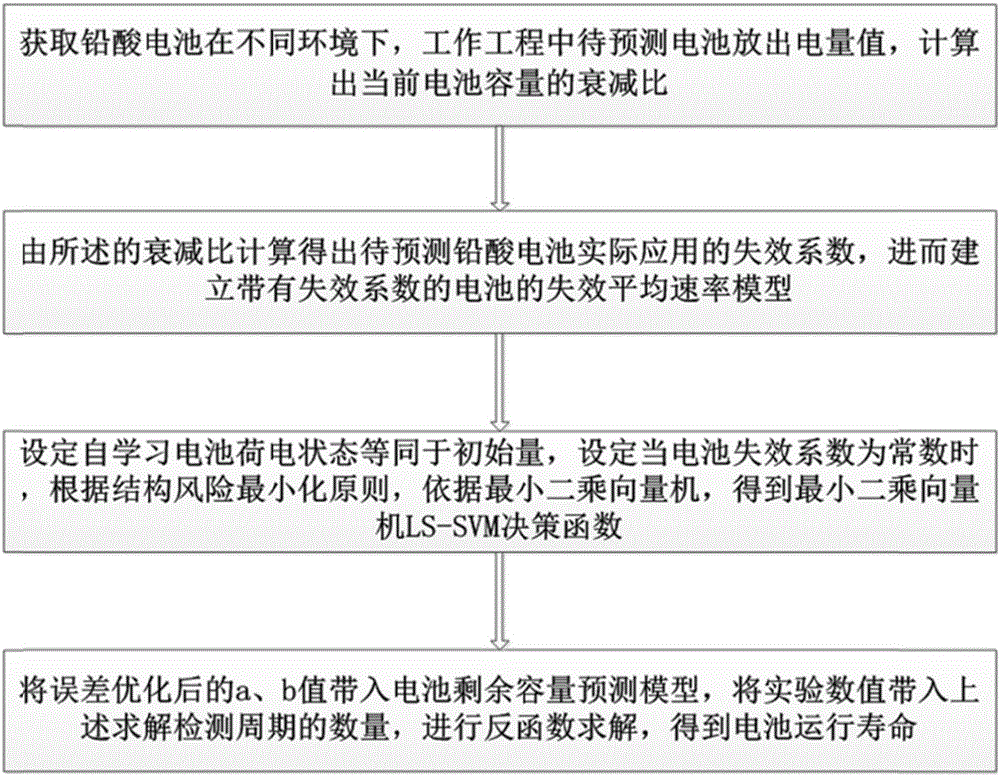

[0040] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

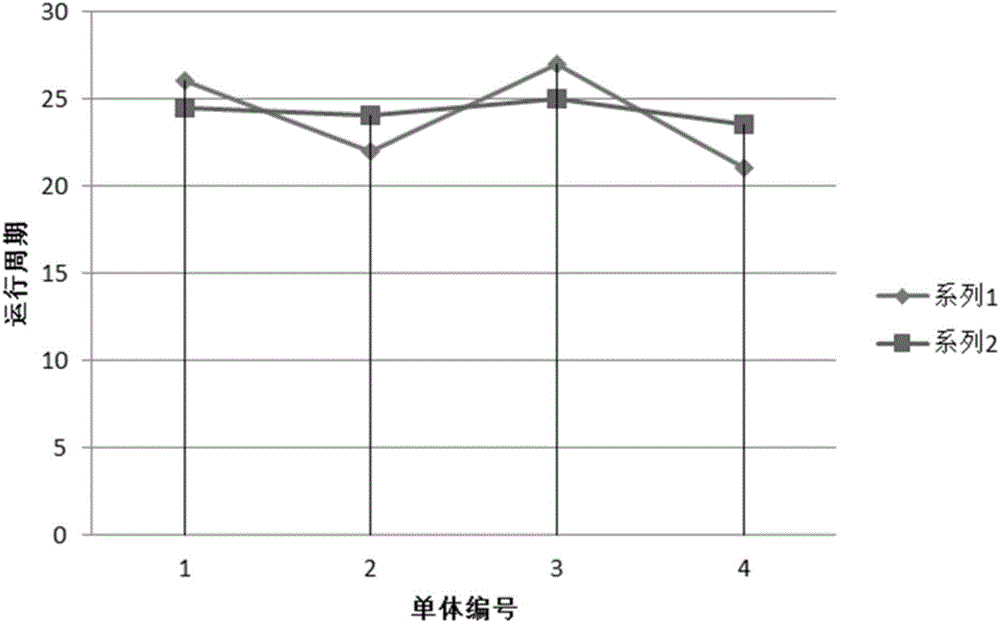

[0041] Examples such as Figure 1-Figure 3 As shown, in this embodiment, it is assumed that 1 lead-acid battery operation performance removes the influence of physical damage factors; it is assumed that 2 lead-acid batteries can be charged in time after running and discharging, so as not to be affected by vulcanization; 400AH second-class valve-regulated lead Acid battery cells were used as research samples.

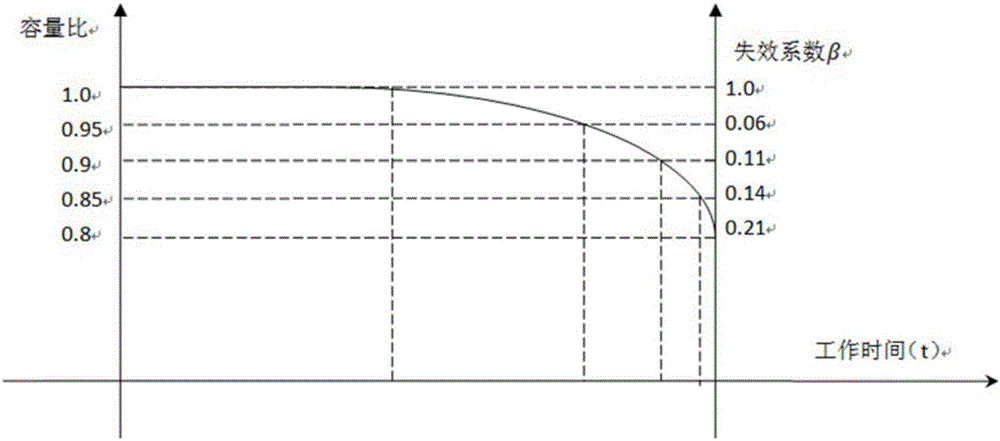

[0042] Step 1: Analyze the factors that affect the performance degradation of lead-acid batteries, the relationship between performance degradation and changes in various operating parameters, and determine the parameters that affect the performance degradat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com