Wireless timing method for recording type fault indicator

A fault indicator, wireless technology, applied in radio-controlled timers, instruments, measuring devices, etc., can solve problems such as fault indicator clock deviation, and achieve the effects of controllable time accuracy, cost reduction, and improved energy management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

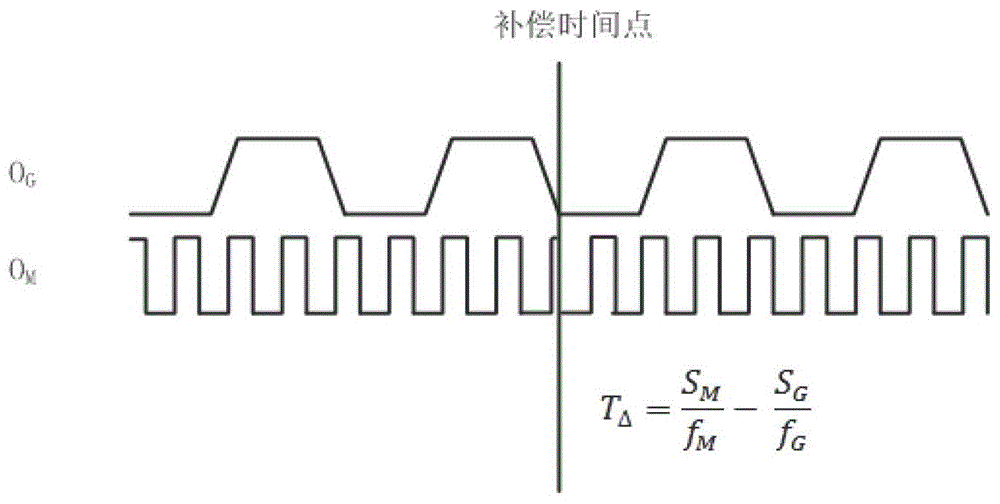

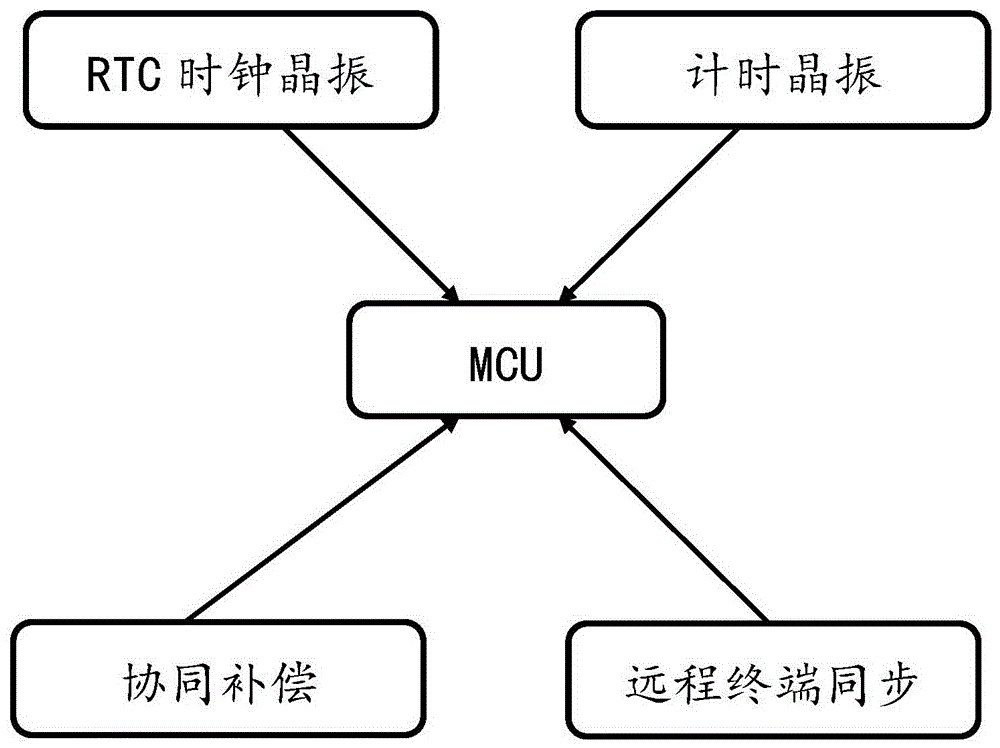

[0022] see figure 1 and figure 2 As shown, a wireless timekeeping method for a wave-recording type fault indicator of the present invention is used to solve the high-precision time-setting and time-keeping requirements of a fault indicator with a wave-recording function.

[0023] (1) The method of using multi-crystal oscillators to work together.

[0024] (2) The time calibration step is 1 μs, and the clock deviation of the three-phase fault indicator can reach within 25 μs.

[0025] (3) This method has the characteristics of ultra-low power consumption and low cost.

[0026] Using multi-crystal oscillators to work together, at least one medium-precision high-frequency timing crystal oscillator and one high-precision low-frequency RTC clock crystal oscillator should be configured. The high-frequency medium-precision crystal oscillator is calibrated by the low-frequency high-precision crystal oscillator, and the high-frequency crystal oscillator provides compensation data t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com