Voltage tracking/embedded circuit

A voltage tracking and clamping technology, applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., can solve the problems of output waveform deterioration, inability to overcome the influence of phase compensation capacitor speed, slow response, etc., to improve common mode rejection Ratio, improve zero drift suppression ability, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

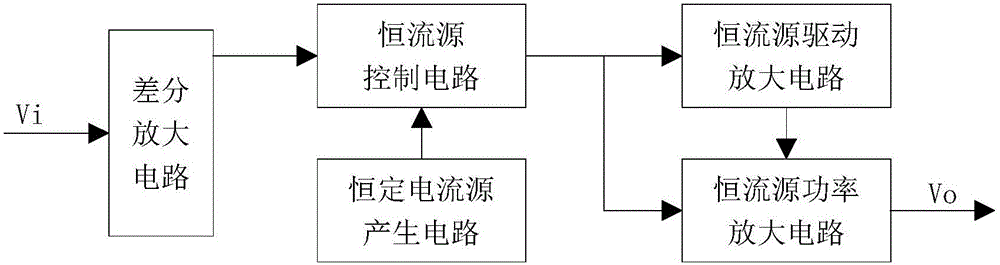

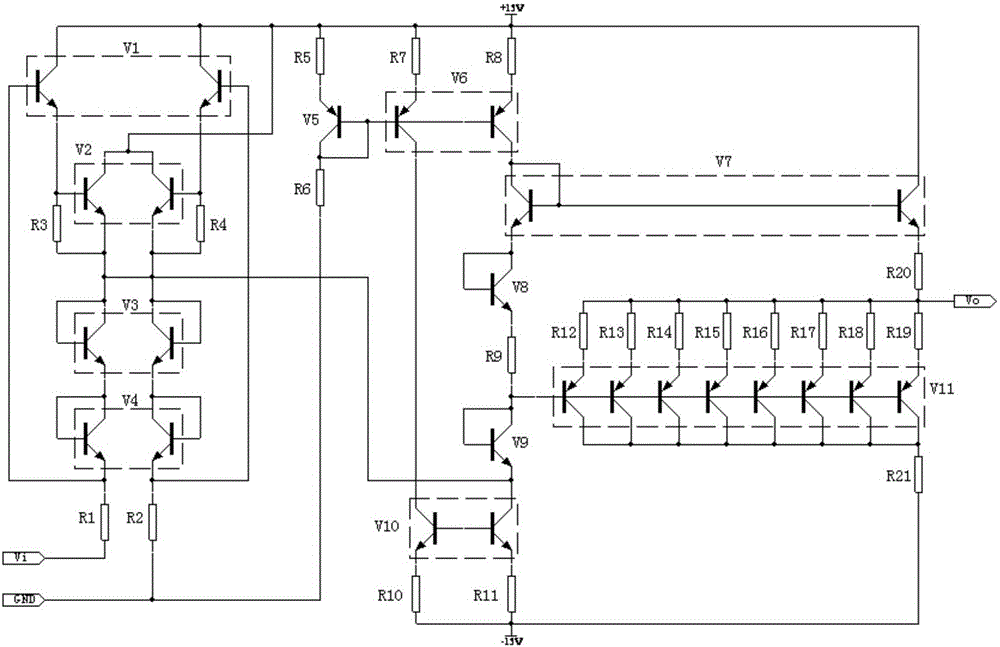

[0020] like figure 1 As described above, a voltage tracking / clamping circuit includes a differential amplifier circuit, a constant current source generating circuit, a constant current source control circuit, a constant current source drive amplifier circuit, and a constant current source power amplifier circuit. The differential amplifier circuit is located at the input end as The preamplifier converts the voltage error signal into a current signal, and the converted current signal flows into the constant current source control circuit, and the current signal flowing into the constant current source control circuit performs a current proportional control operation with the constant current generated by the constant current source generating circuit, The constant current source signal is obtained after the current proportio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com