Predicting method of titanium alloy shot peening strengthening remnant stress field

A shot peening and residual stress technology, used in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as poor prediction accuracy, large testing workload, and difficult residual stress field control, and achieve high accuracy. , fast prediction speed, reliable effect of design and analysis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

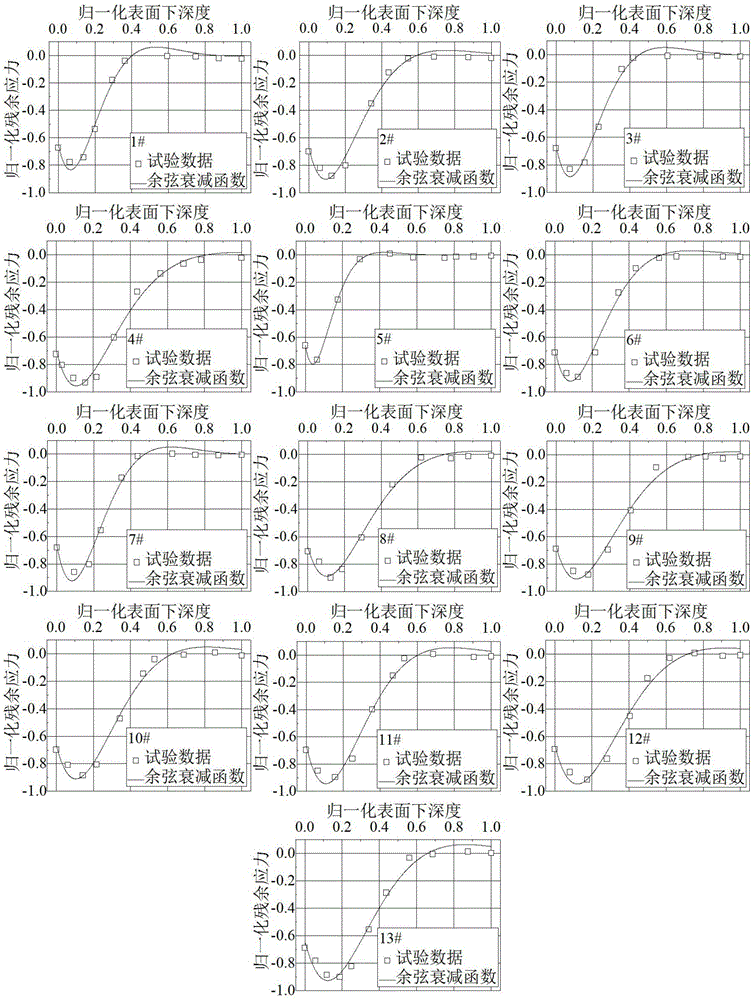

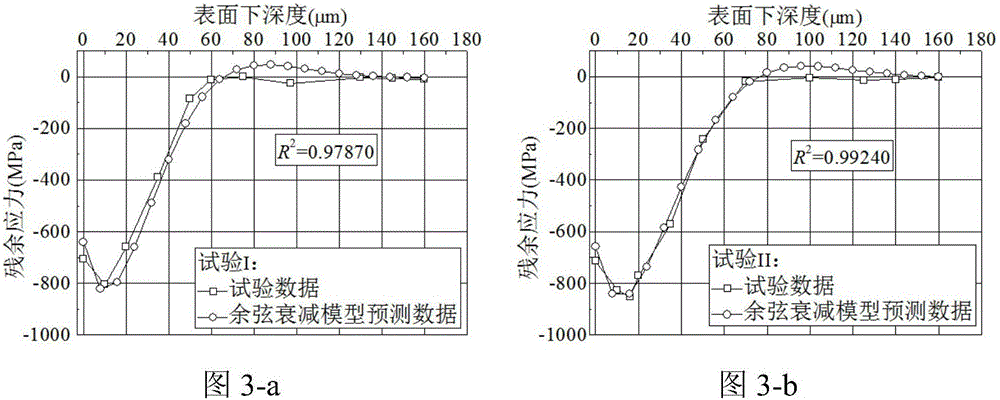

[0062] Embodiment 1, a method for predicting residual stress field of titanium alloy shot peening based on characteristic parameters and cosine decay function

[0063] The prediction method of this embodiment is carried out as follows:

[0064] Step 1: Determine the characteristic parameter model of the residual stress field of shot peening

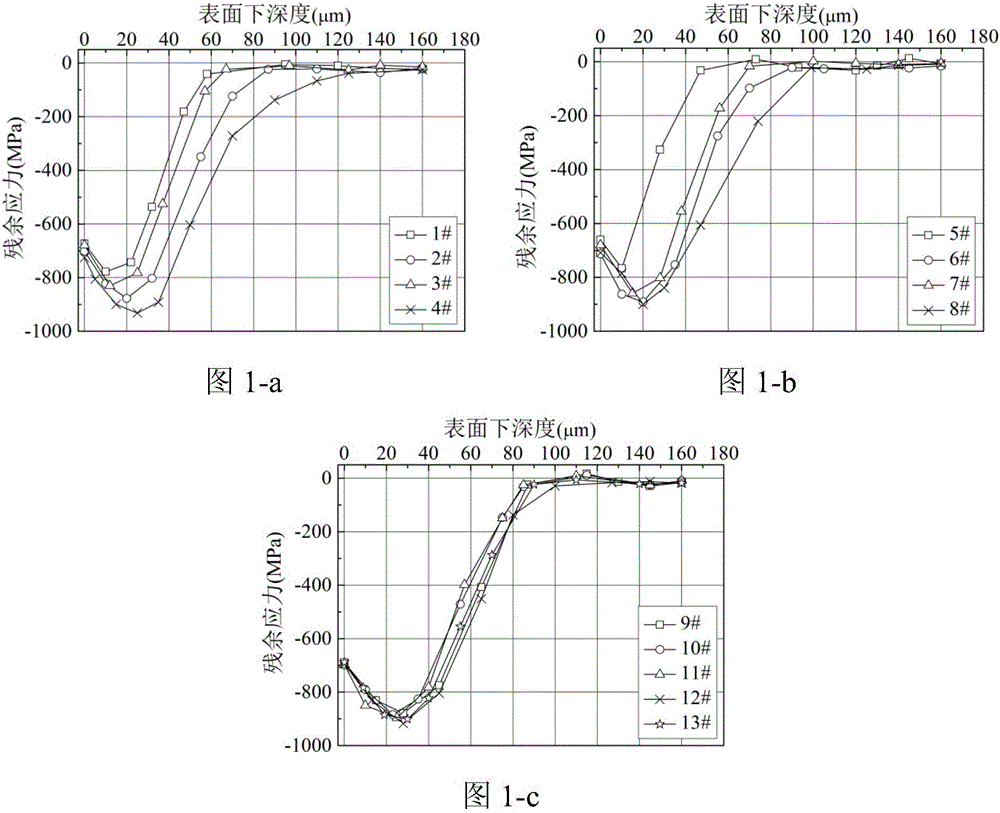

[0065] The surface residual compressive stress σ of the titanium alloy material srs 、Maximum residual compressive stress σ mcrs , The maximum residual compressive stress from the surface distance Z m , Residual stress field depth Z 0 As the four characteristic parameters that characterize the residual compressive stress field, a quadratic polynomial model is used to characterize the relationship between the characteristic parameters of the residual stress field and the shot peening process parameters.

[0066]

[0067] Where c ii Is the process parameter coefficient; X 1 , X 2 It is the coded value of shot peening intensity and coverage.

[0068]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com