Pressure-proof heat preservation battery compartment

A battery compartment and pressure-resistant technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve problems such as equipment failure, harsh environment, and impact on battery performance, so as to avoid storage and discharge capabilities and meet voltage-resistant requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

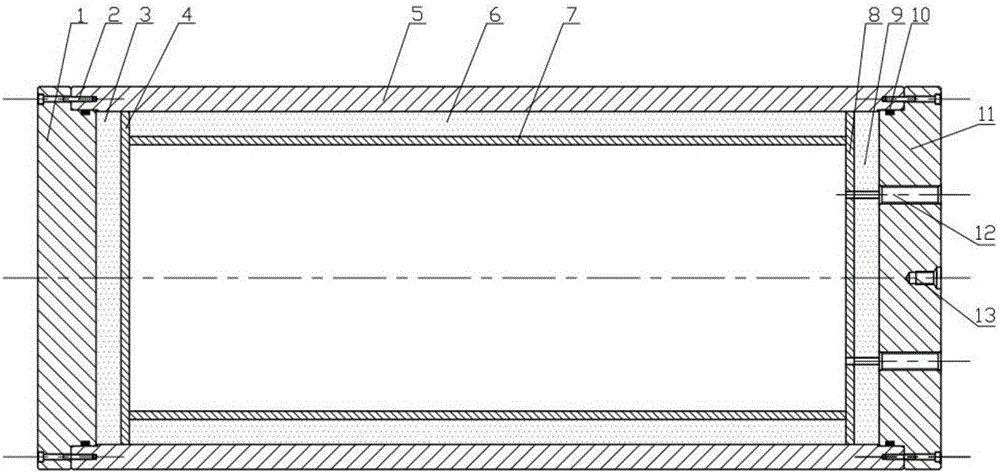

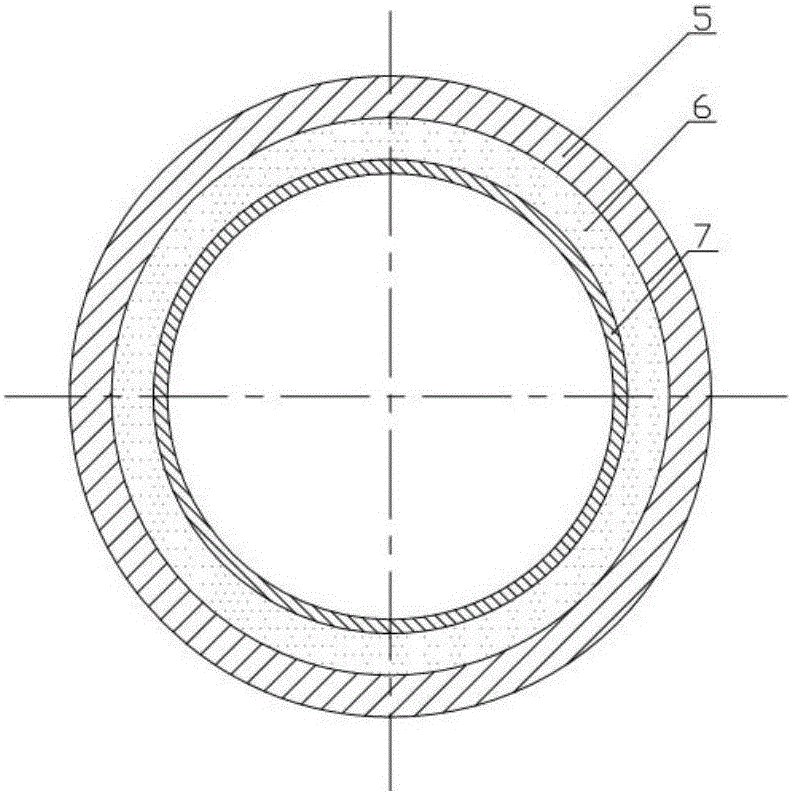

[0013] 1. Structural connection method. The lower flat cover head 1 and the stainless steel cylinder 5 are connected by screws 2, the lower flat cover head 1 and the stainless steel cylinder 5 are sealed by an O-ring 10, and the lower flat cover head 1 and the lower flat cover are combined with a polyurethane foam insulation layer 3 bonded together, the lower flat cover composite polyurethane foam insulation layer 3 and the lower flat cover high-density polyethylene protective layer 4 are bonded together, the stainless steel cylinder 5 and the cylinder composite polyurethane foam insulation layer 6 are bonded together, the cylinder The composite polyurethane foam insulation layer 6 of the body is bonded together with the high-density polyethylene protective layer 7 of the cylinder, and the high-density polyethylene protective layer 8 of the upper flat cover is bonded together with the composite polyurethane foam insulation layer 9 of the upper flat cover. The composite polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com