Winding head for lamination stacking machine and working method thereof

A technology of winding head and lamination machine, applied in the direction of sustainable manufacturing/processing, electrochemical generator, electrical components, etc., can solve the problems of increased width, inaccurate stroke, insufficient stroke, etc., to reduce friction , to avoid stuck, fast action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

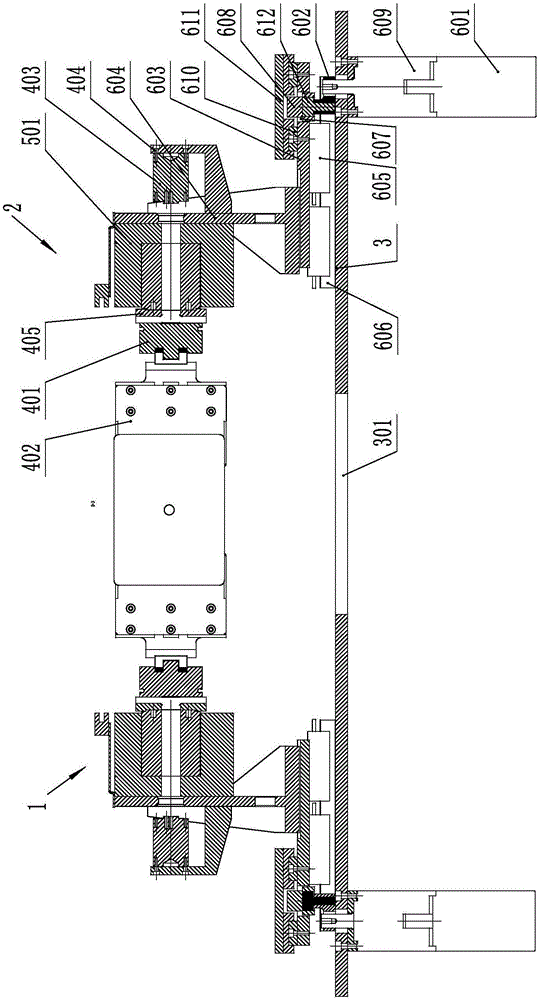

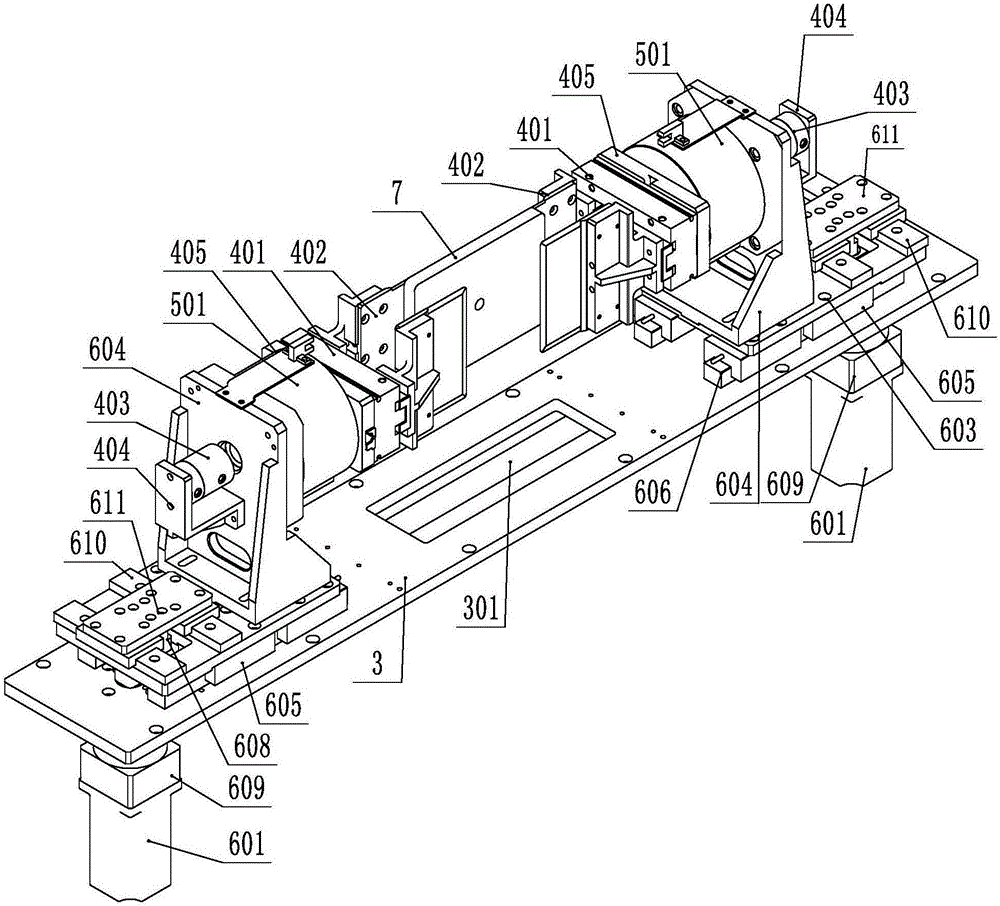

[0030] Such as figure 1 , 2 As shown, the present invention includes a horizontally arranged fixed plate 3, left and right winding heads 1, 2 symmetrically arranged on the fixed plate 3, and the left and right winding heads 1, 2 each include a The clamping mechanism of the sheet 7, the rotating mechanism for reciprocating intermittent 180-degree rotation, and the moving mechanism for driving the clamping mechanism forward or backward; the moving mechanism includes a moving motor 601, an eccentric motor driven by the moving motor 601 Components, the slide plate 603 connected with the eccentric part and the fixed seat 604 connected with the slide plate 603 can drive the clamping mechanism to move left and right; the middle part of the fixed plate 3 is provided with a diaphragm hole 301 for piercing the diaphragm; When rotating, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com