LTCC (Low-temperature co-fired ceramic) filter manufacturing method and LTCC filter

A technology of filters and intermediate conductors, which is applied in the field of printed components, can solve the problems of low electrical connection rate of LTCC filter ports, low electrical connection rate, and increased manufacturing costs, and achieve microwave performance and consistency of various indicators. The effect of improving product qualification rate and electrical connection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are a further description of the content of the present invention as an explanation of the technical content of the present invention, but the essential content of the present invention is not limited to the following examples, those of ordinary skill in the art can and should know any Simple changes or replacements of the essential spirit of the invention shall fall within the scope of protection required by the present invention.

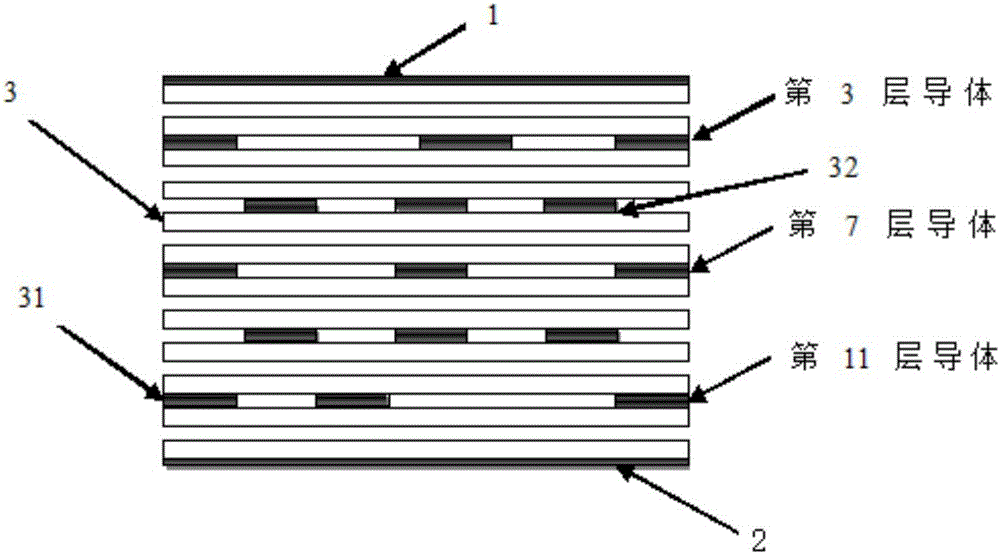

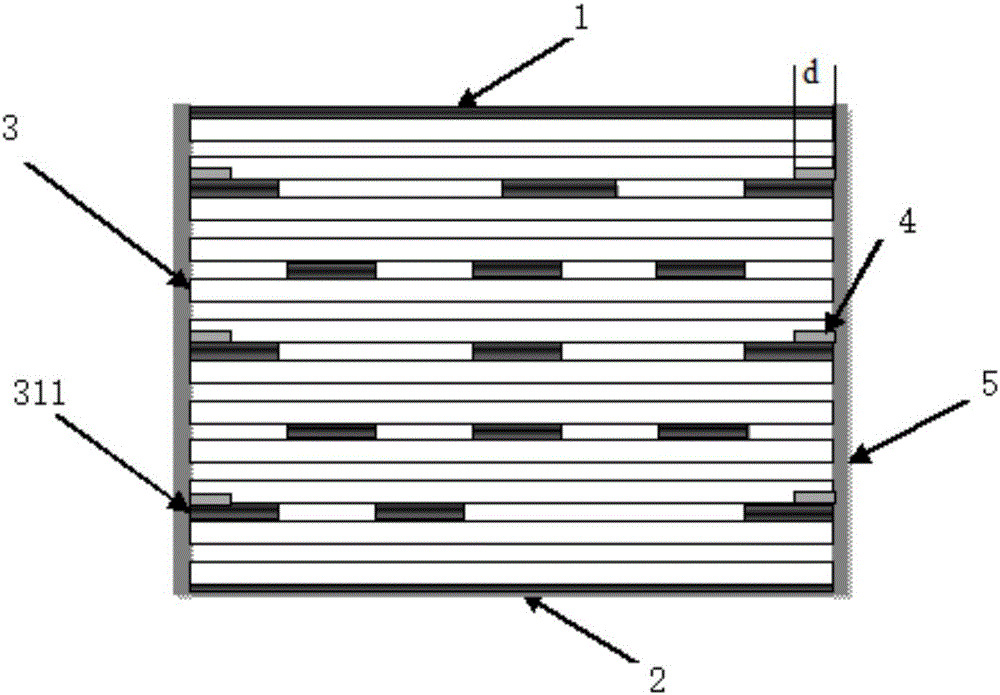

[0028] In the LTCC filter, the sintering thickness of the intermediate conductor layer is designed to be about 8 μm. After measurement, it is found that the exposed thickness of the end of the conduction band of the intermediate layer of the finished filter after sintering is very thin, and the outline of the exposed conduction band is very vague, and part of it is covered by the ceramic material. cover.

[0029] It is for this reason that the exposed terminal is in poor contact with the printed conductor on the side....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap