Rapid auto arranging and forming technology of mica sheet and copper bar in row commutator

A forming technology and mica chip technology, applied in the field of automatic chip inserting machines, can solve the problems of inability to meet the needs of large-scale production, low plug yield, low production efficiency, etc. The effect of reliable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

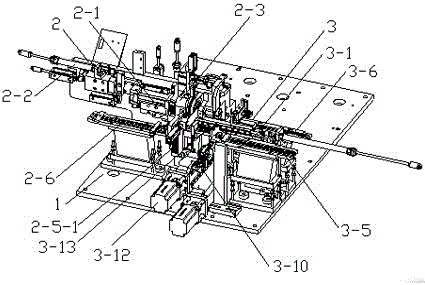

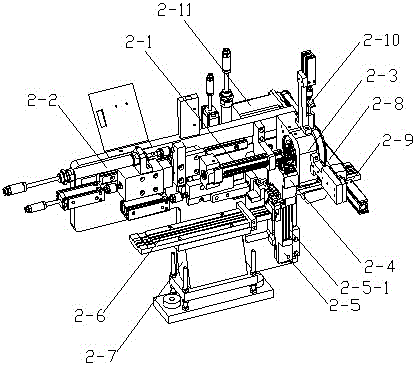

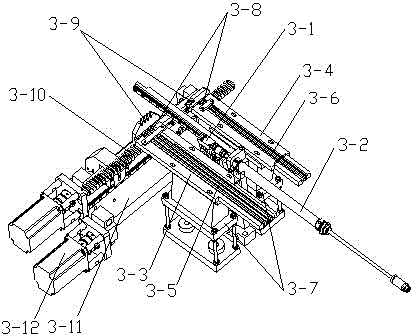

[0022] like Figure 1-Figure 4 As shown, the specific embodiment adopts the following technical scheme: it comprises a substrate 1, a copper sheet supply device 2 and a mica supply device 3, and the substrate 1 is provided with a copper sheet supply device 2 and a mica supply device 3, wherein the copper sheet supply The device 2 is composed of a copper sheet pusher 2-1, a cylinder driving body 2-2, a copper sheet mica collecting round sleeve 2-3, a copper sheet mica collecting channel device 2-4, a copper sheet pushing mechanism 2-5, Composed of copper sheet feeding track 2-6, linear direct vibration 2-7, stopper device 2-8, mica feeding channel 2-9, indexing circle positioning device 2-10, stepper motor drive 2-11, copper sheet One end of the pusher 2-1 is connected with a cylinder driving body 2-2, and the other end of the copper sheet pusher 2-1 is provided with a copper sheet mica collection round sleeve 2-3, and the copper sheet pusher 2-1 is connected with the copper sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com