Method of Suppressing Mechanical Resonance in Servo Control System

A servo control system and mechanical resonance technology, applied in observer control, motor vibration suppression control, etc., can solve problems such as control performance decline, complex engineering application, poor robustness to external disturbances, etc., to suppress low-frequency mechanical resonance and achieve simple implementation , Improve the effect of servo control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

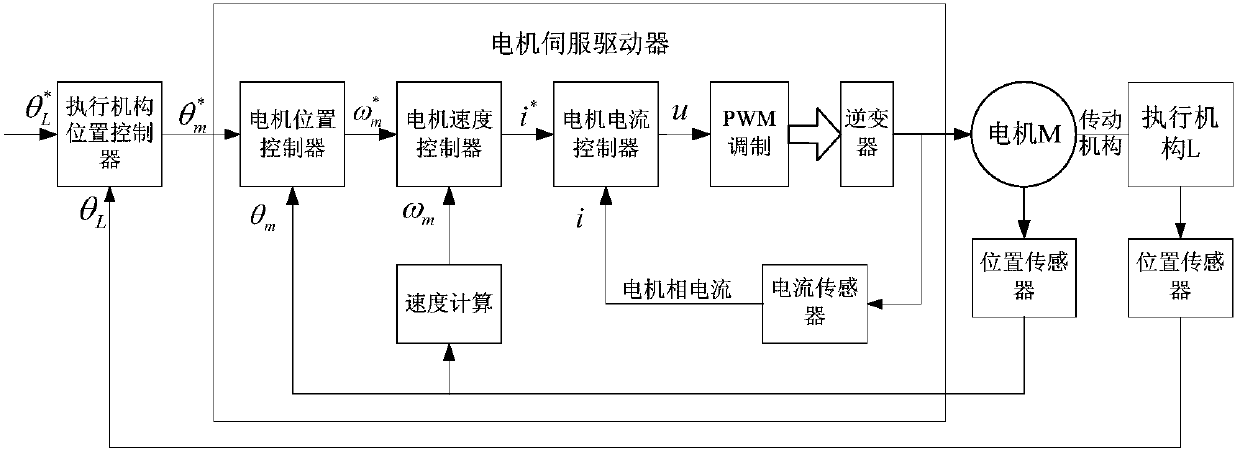

[0019] Such as figure 1 As shown, the motor M, the transmission mechanism, and the actuator L of the servo control system form a typical dual-inertia mechanical transmission system. The motor M and the actuator L are connected through a transmission mechanism, and the stiffness of the transmission mechanism is K g . When the transmission mechanism is twisted and deformed, a torque T will be generated w , this torque can be regarded as the load torque of the motor M for the motor M, and it can be regarded as the driving torque for the actuator L. The motor servo driver controls the operation of the motor M and provides electromagnetic torque T for the shaft of the motor M e . At the end of the motor M, the electrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com