Constant-power LED driving system and constant-power control method

A LED driving, constant power technology, applied in the use of semiconductor lamps, electrical components, electroluminescent light sources, etc., can solve the problems of being susceptible to interference, maintaining constant, high negative voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the following, the technical solutions of the present invention will be clearly and completely described in conjunction with various embodiments. However, the described embodiments are only the embodiments used for the description of the present invention and not all the embodiments. Based on these embodiments, the present invention The solutions obtained by those skilled in the art without creative work all fall within the protection scope of the present invention.

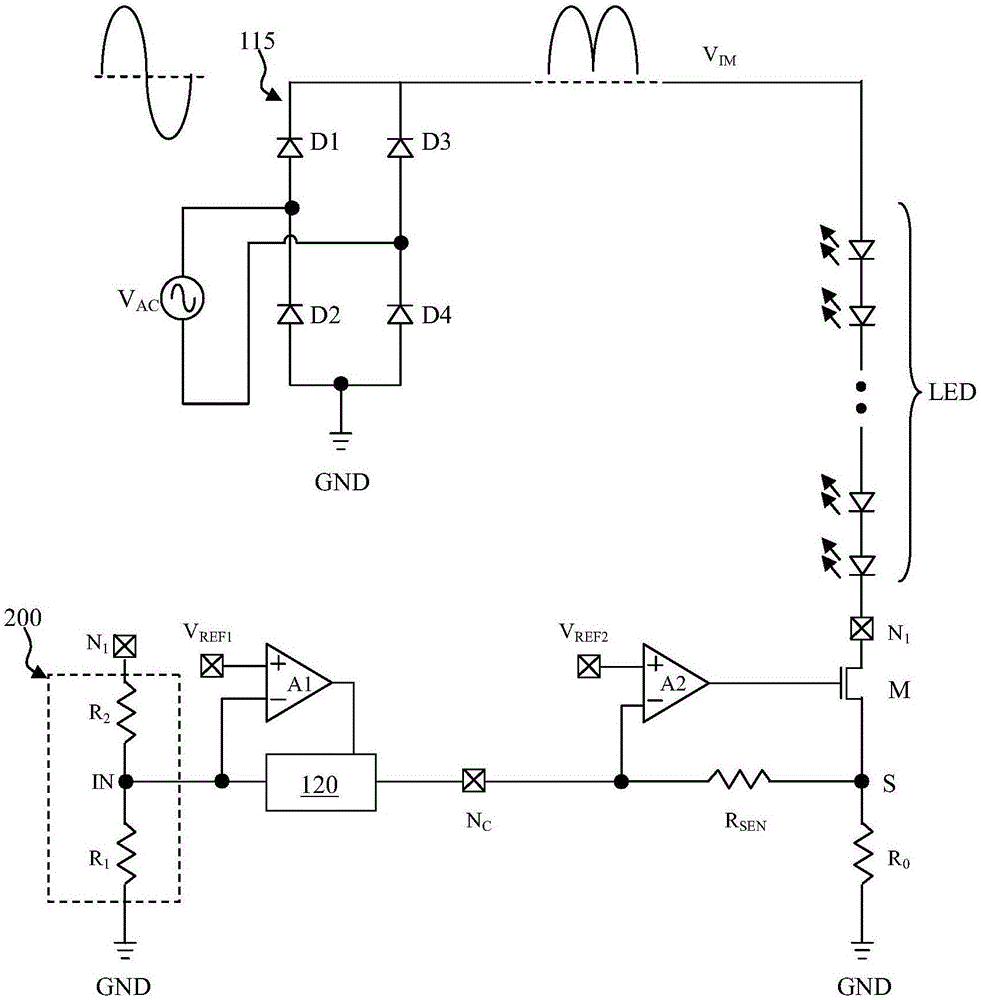

[0042] See figure 1 , Is the basic topology of the constant power control circuit, AC mains V AC From AC grid, AC mains V AC Full-wave rectification is performed by the bridge rectifier 115. The bridge rectifier 115 has four diodes D1-D4 and belongs to the prior art. The voltage output by the bridge rectifier 115 is a fluctuating pulsating voltage V IM . Pulsating voltage V IM It is used to supply power to the series of light-emitting diode strings. The cathode of the former diode in the series of diod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com