Walking type electric weeding machine

A weeding machine and walk-behind technology, which is applied in the field of mechanical equipment, can solve the problems of high labor intensity and low efficiency of weeding, and achieve the effects of low labor intensity, convenient use and high weeding efficiency in field operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment of description, the present invention is described in further detail:

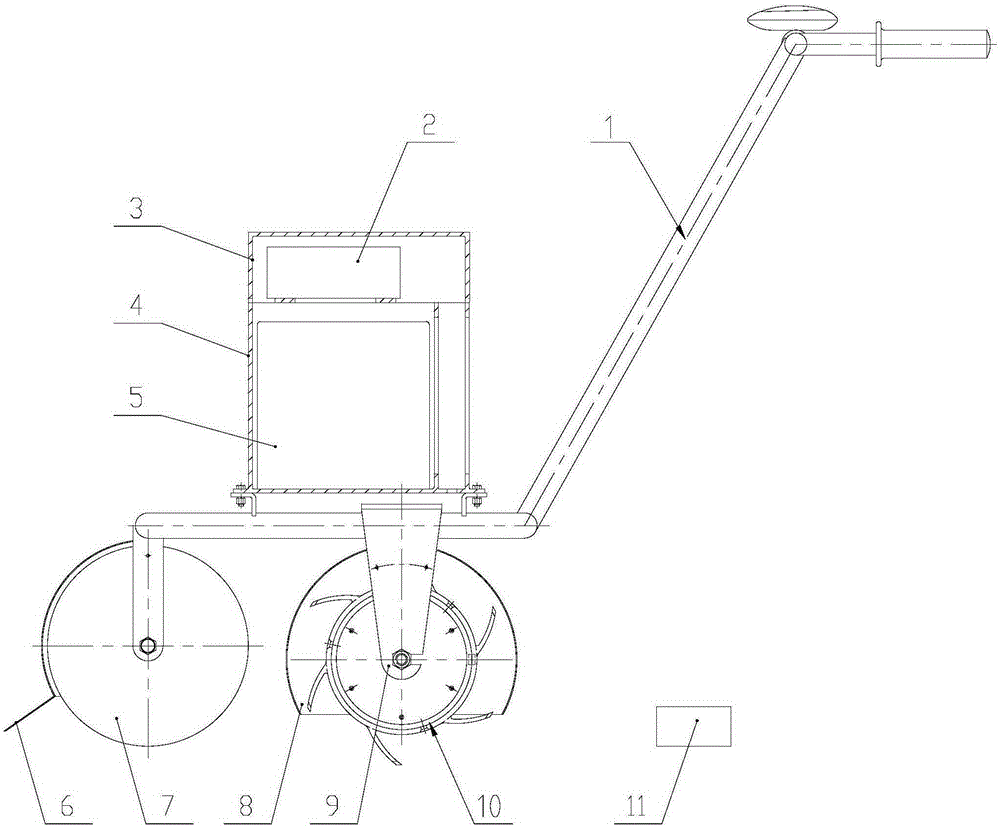

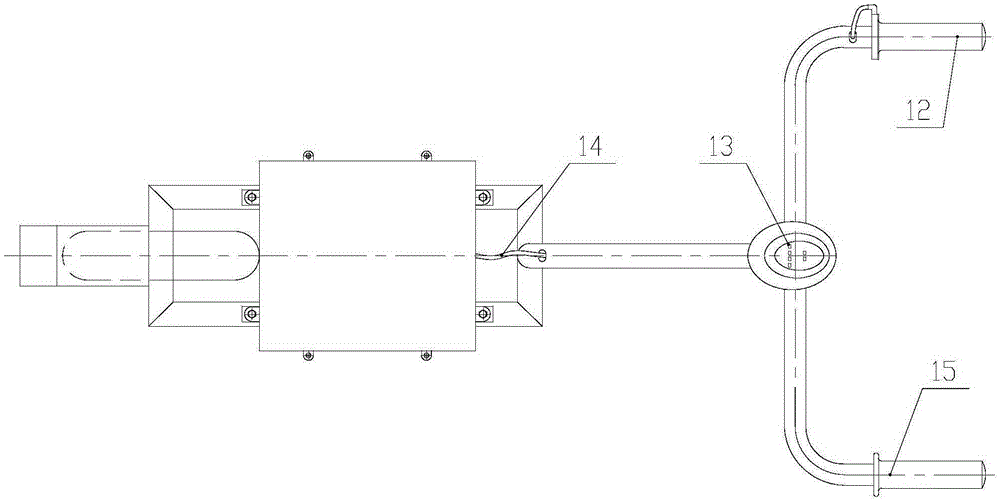

[0027] Such as figure 1 and figure 2 As shown, a walk-behind electric weeder is mainly composed of a frame 1, a controller 2, a controller box 3, a battery box 4, a battery 5, a wheel guard 6, a wheel 7, a protective cover 8, a knife rest 9, a rotating Cutter 10, charger 11, handle 12, instrument panel 13, electric wire 14, handle 15 and some standard components form.

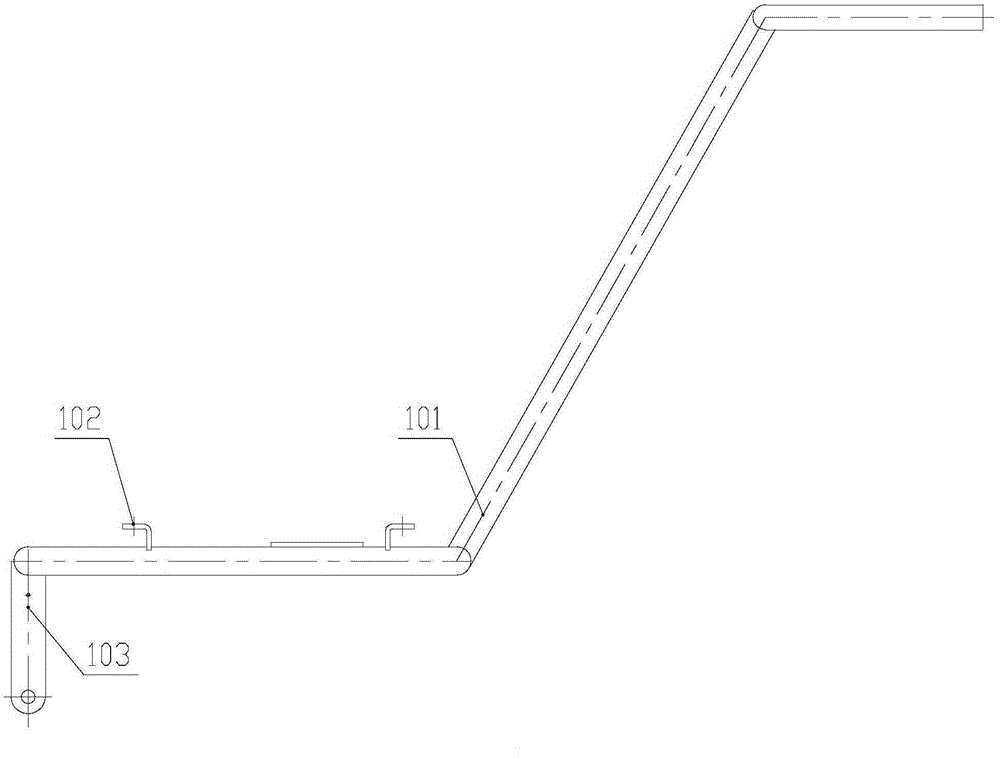

[0028] Such as image 3 and Figure 4 As shown, the frame 1 has a symmetrical structure as a whole, and is welded by pipe fittings and plates, including inclined pipes 101, lugs 102, support plates 103, support frames 104, backing plates 105, and handrails 106; the support frame 104 consists of a right straight pipe 1041, the front horizontal pipe 1042, the left straight pipe 1043, and the rear horizontal pipe 1044 are welded end to end. One end of the inclined pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com