System and method for safety adjustment of automatic puncture

An adjustment system and automatic technology, which is applied in the field of medical devices, can solve problems such as being single and unable to meet the safety requirements of automatic puncture equipment, and achieve the effect of ensuring reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

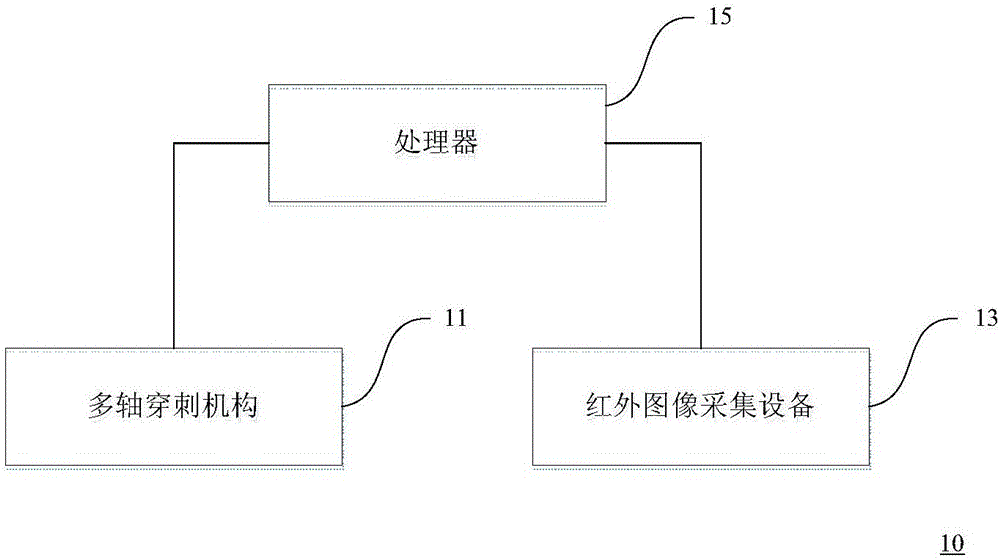

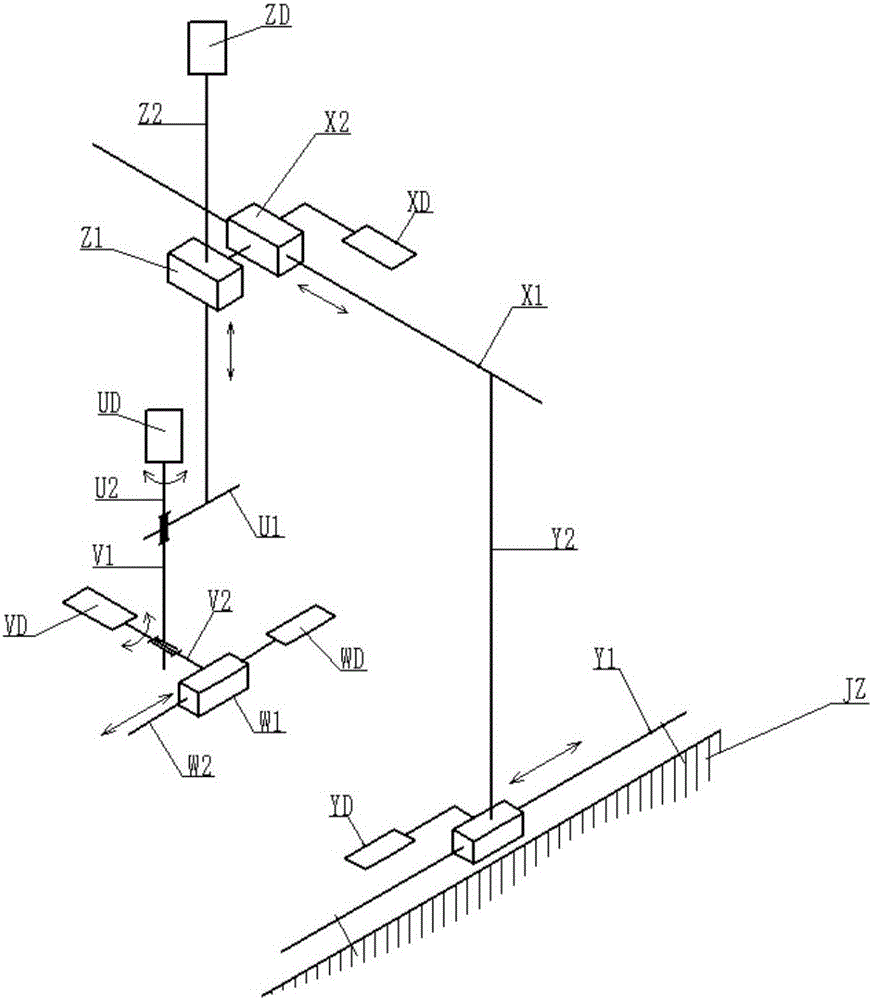

[0039] See figure 1 , figure 1 It is a schematic structural diagram of an automatic puncture device provided by an embodiment of the present invention. The automatic puncture device 10 includes: a multi-axis puncture mechanism 11 , an infrared image acquisition device 13 and a processor 15 . Among them, after the patient puts his arm into the automatic puncture device and fixes it, the infrared image acquisition device 13 collects the infrared image of the patient's arm or hand, and the processor 15 determines the optimal puncture point position according to the infrared image, and then the processing The device 15 controls the multi-axis puncture mechanism 11 to complete the puncture action according to the set trajectory.

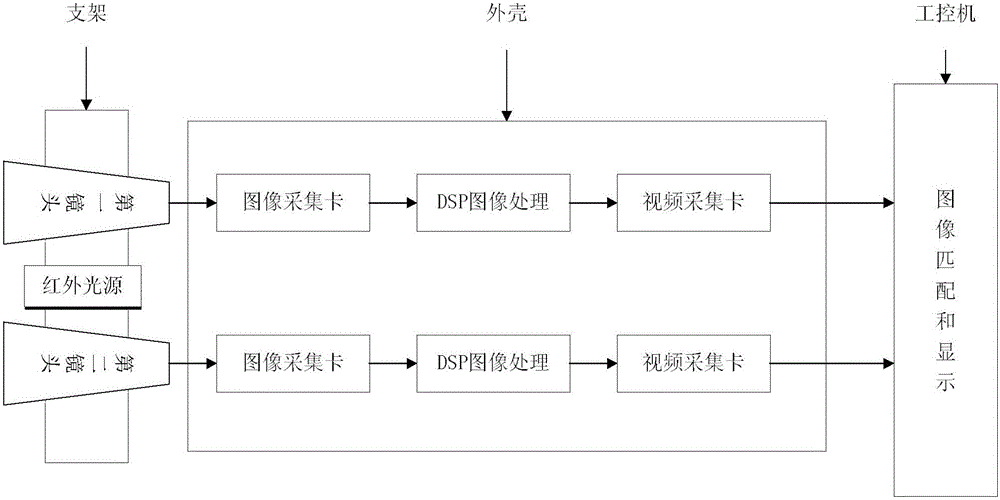

[0040] Among them, see figure 2 , figure 2 It is a schematic structural diagram of a binocular near-infrared imaging device provided by an embodiment of the present invention. The infrared image acquisition device 13 is preferably a binocular near-...

Embodiment 2

[0065] See Image 6 , Image 6It is a schematic diagram of an automatic puncture safety adjustment method provided by an embodiment of the present invention. In this embodiment, on the basis of the foregoing embodiments, the security detection and processing method of the present invention will be described in detail.

[0066] The method can include:

[0067] Detecting whether the multi-axis puncture mechanism is in the zero state after being powered on, and controlling the multi-axis puncture mechanism to perform a zero return program when it is not in the zero state;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com