Spraying method for coating on inner wall of pipeline

A technology for pipelines and coatings, which is applied in the direction of coatings and devices for coating liquid on the surface, etc., which can solve the problems of difficulty in changing the diameter of spraying devices, increasing processing costs, and difficulties in the anti-corrosion and anti-oxidation of the inner wall of the pipeline, etc., to achieve reduction The loss of kinetic energy, the reduction of friction, the effect of strong centrifugal action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

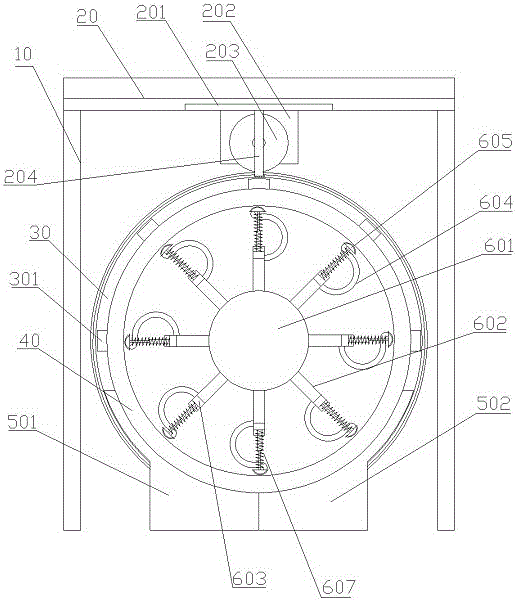

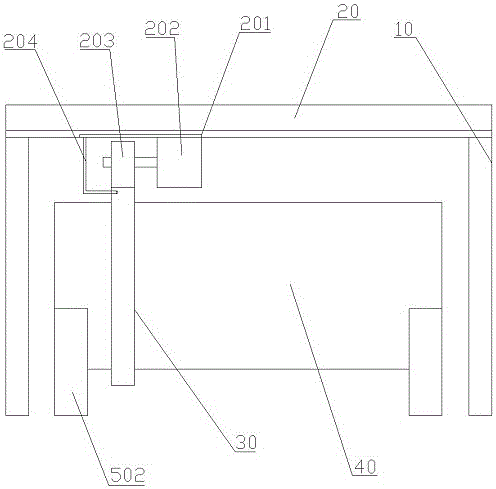

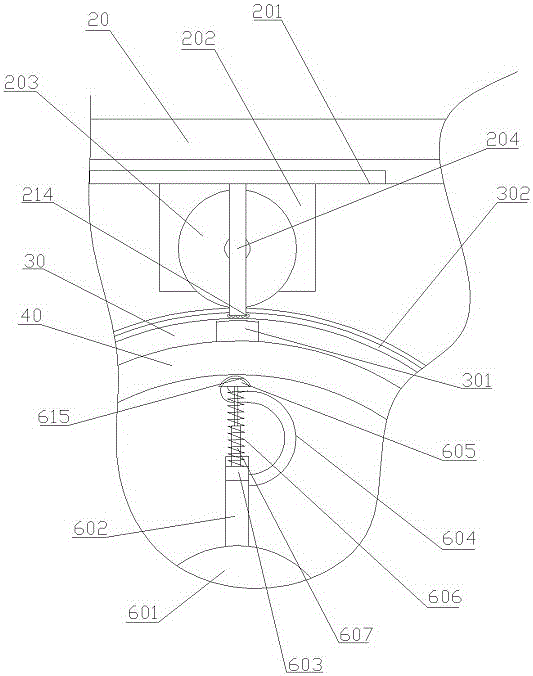

[0022] The reference signs in the accompanying drawings include: frame 10, servo mechanism 20, moving block 201, motor 202, driving gear 203, push rod 204, ball 214, driven gear 30, first magnet 301, chute 302, Pipeline 40, left fixing clip 501, right fixing clip 502, paint containing box 601, branch pipe 602, slider 603, bellows 604, second magnet 605, sponge 615, connecting rod 606, spring 607.

[0023] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown: a magnetic spraying device, including a frame 10, a clamp for fixing the pipeline 40, a driving gear 203, a motor 202, a coating device arranged in the pipeline 40, and a driven gear 30 capable of meshing with the driving gear 203 . The fixing clip is horizontally arranged directly below the frame 10, and a servo mechanism 20 is installed on the top of the frame 10. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com