A steel bridge three-dimensional cross weld structure and its construction method

A construction method and steel structure technology, applied in welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as weak anti-fatigue ability, sudden change in section, cracking and failure of sealing materials for welding holes, etc., and achieve a small maintenance workload , Reliable force, conducive to the effect of structural force safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but it does not constitute a limitation of the present invention, and is only used as an example. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

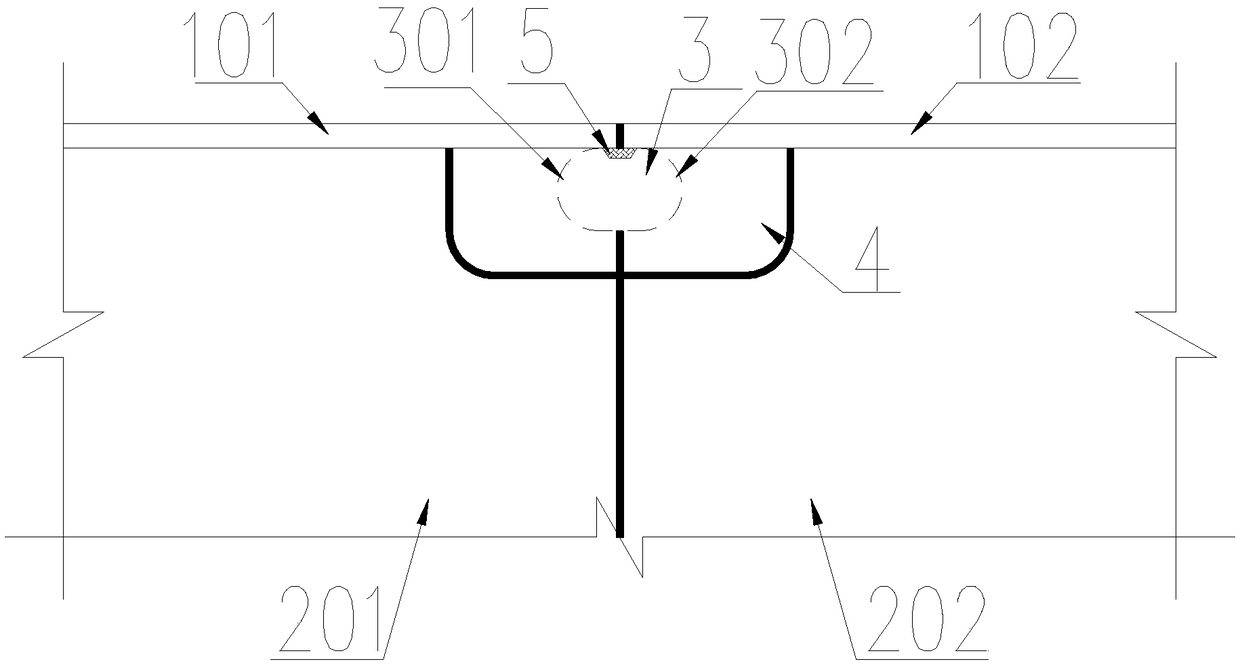

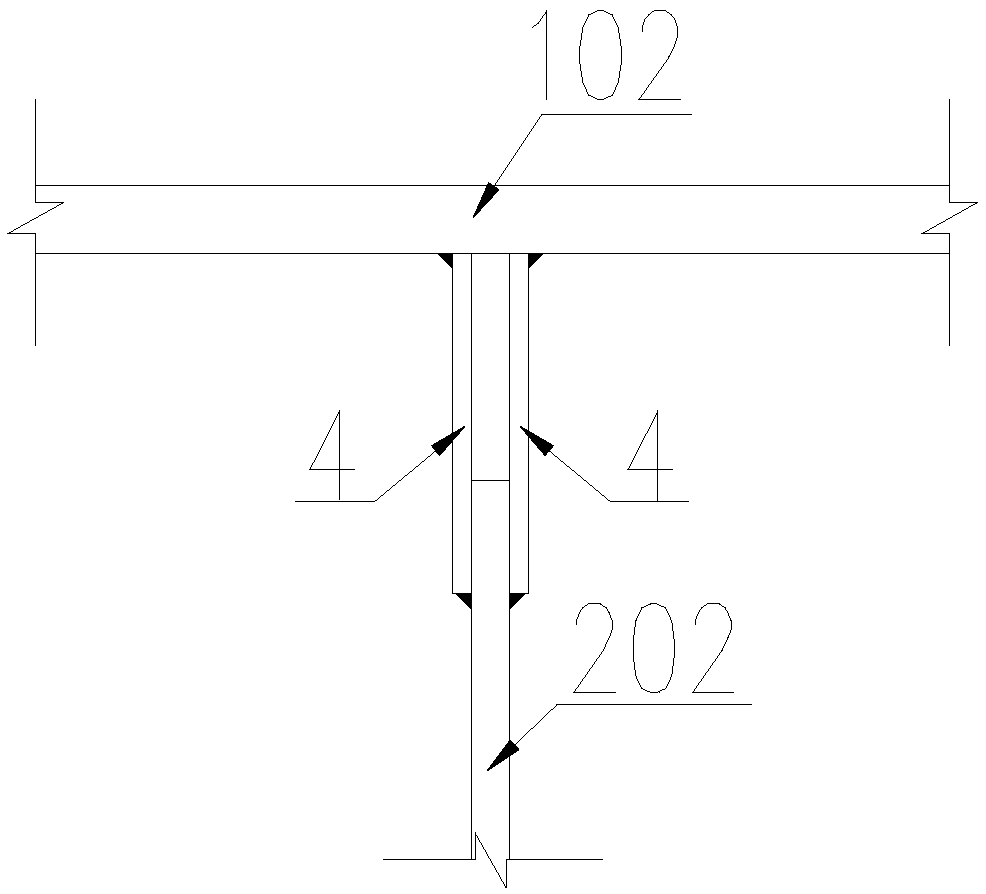

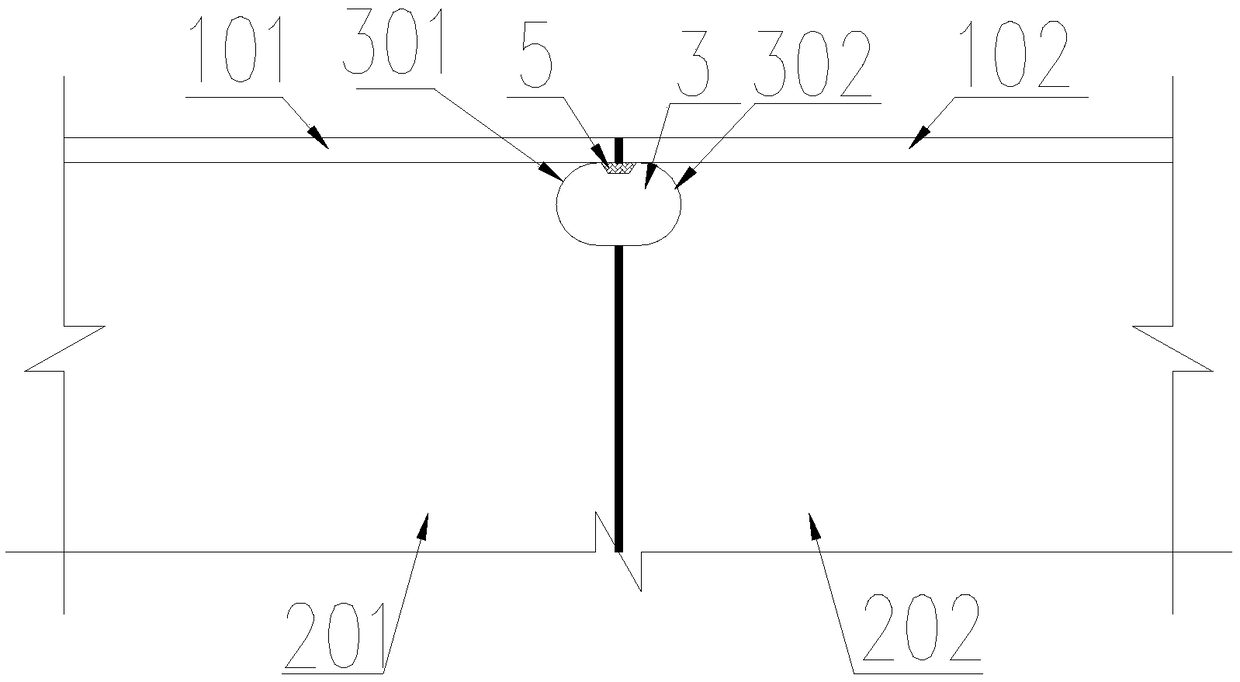

[0023] to combine figure 1 , figure 2 , image 3 It can be seen that a steel bridge three-dimensional cross weld structure includes webs and flanges welded perpendicularly to each other, and is characterized in that: the side of the first web 201 of the web and the bottom surface of the first flange 101 of the flange are vertically The first steel structure unit is formed by welding, the side of the second web 202 of the web is longitudinally welded with the bottom surface of the second web 102 of the wing to form a second steel structure unit, the first web 201 and the second web The side edge of the plate 202 is respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com