A wire drawing tool for luggage rack cover

A luggage rack and wire drawing technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve the problems of corrosive cleaning liquid, health impact of employees, and low insertion efficiency, so as to achieve reliable quality and avoid manual wiping , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

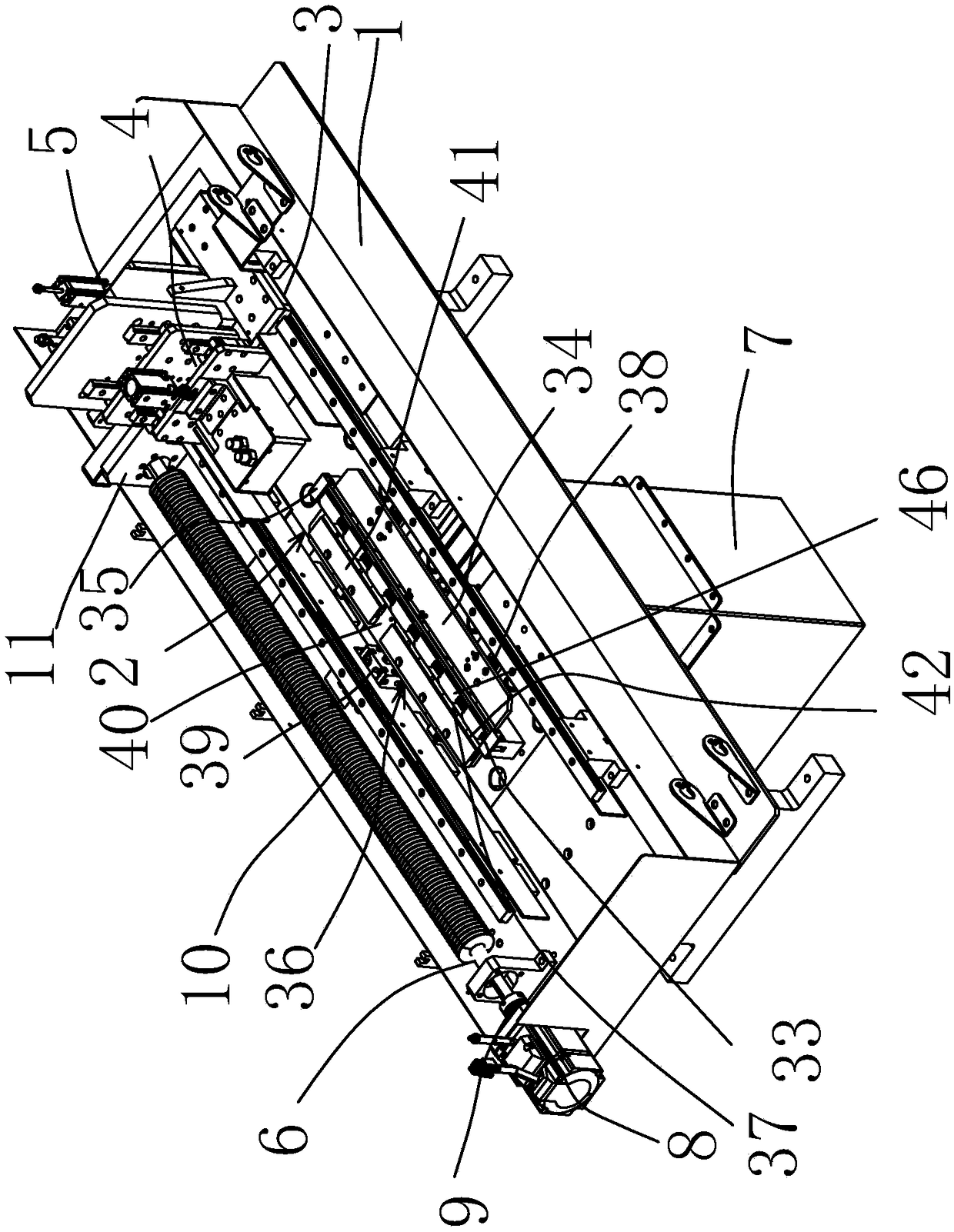

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

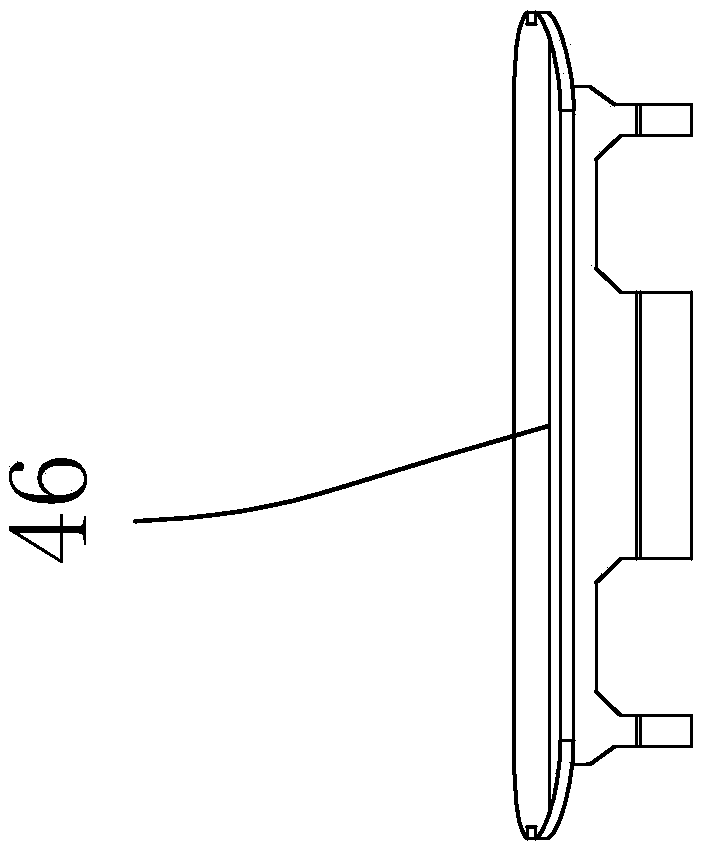

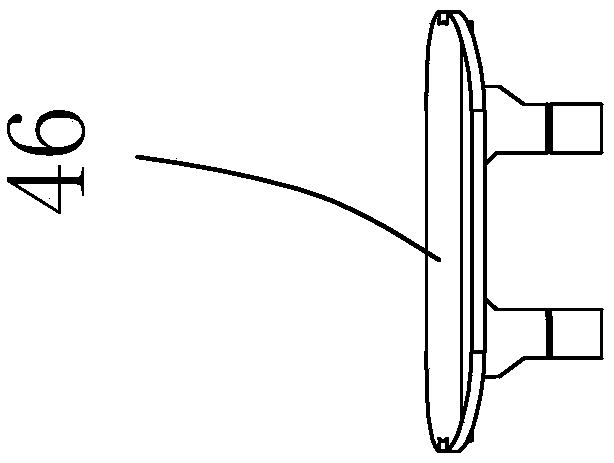

[0031] In the figure, bottom plate 1; placement positioning component 2; slide rail slider component 3; wire drawing component 4; cleaning component 5; sliding power component 6; waste material funnel 7; servo motor 8; Plate 11; cleaning fixed plate 12; cleaning lifting cylinder 13; cleaning bottom plate 14; ; Cleaning cloth 21; Nozzle fixing plate 22; Cleaning water spraying parts 23; Drawing lifting cylinder 24; Drawing lifting plate 25; Drawing floating slider slide rail parts 26; ;Water jet fixed plate 30; drawing water jet parts 31; air blow parts 32; main clamp body 33; positioning block 34; Positioning and clamping slide rail pad 38; positioning cylinder 39; clamping push plate 40; pressing guide block 41; pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com