Dust-free oblique cutting saw and achieving method thereof

A miter saw and dust blocking technology, applied in circular saws, sawing equipment, portable motorized circular saws, etc., can solve problems such as affecting physical health and working environment, prone to failures, and dust flying all over the sky, and achieves a simple structure. , low cost, convenient cleaning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

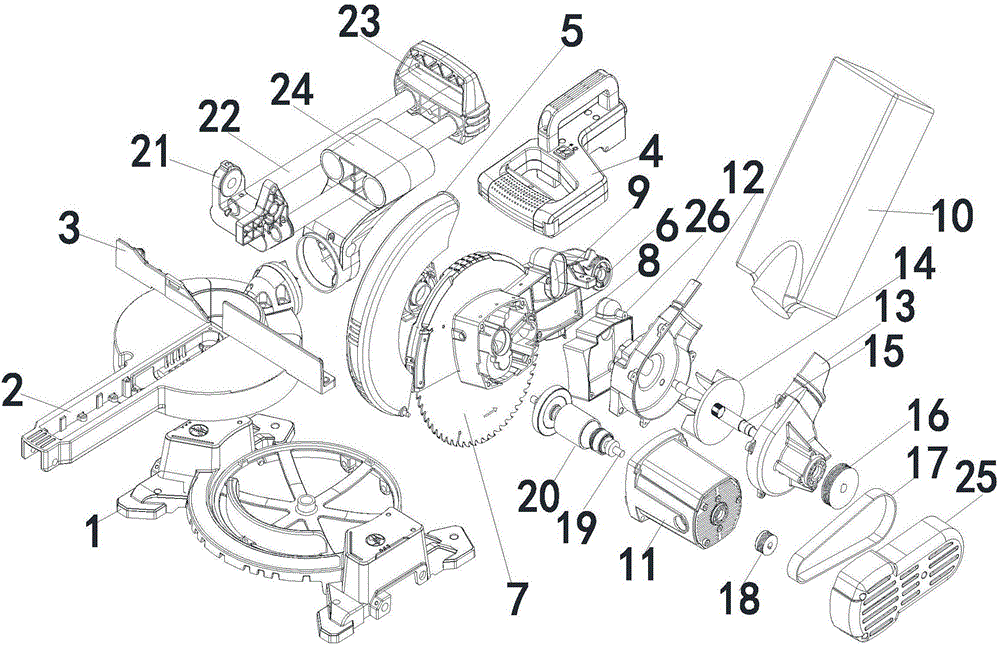

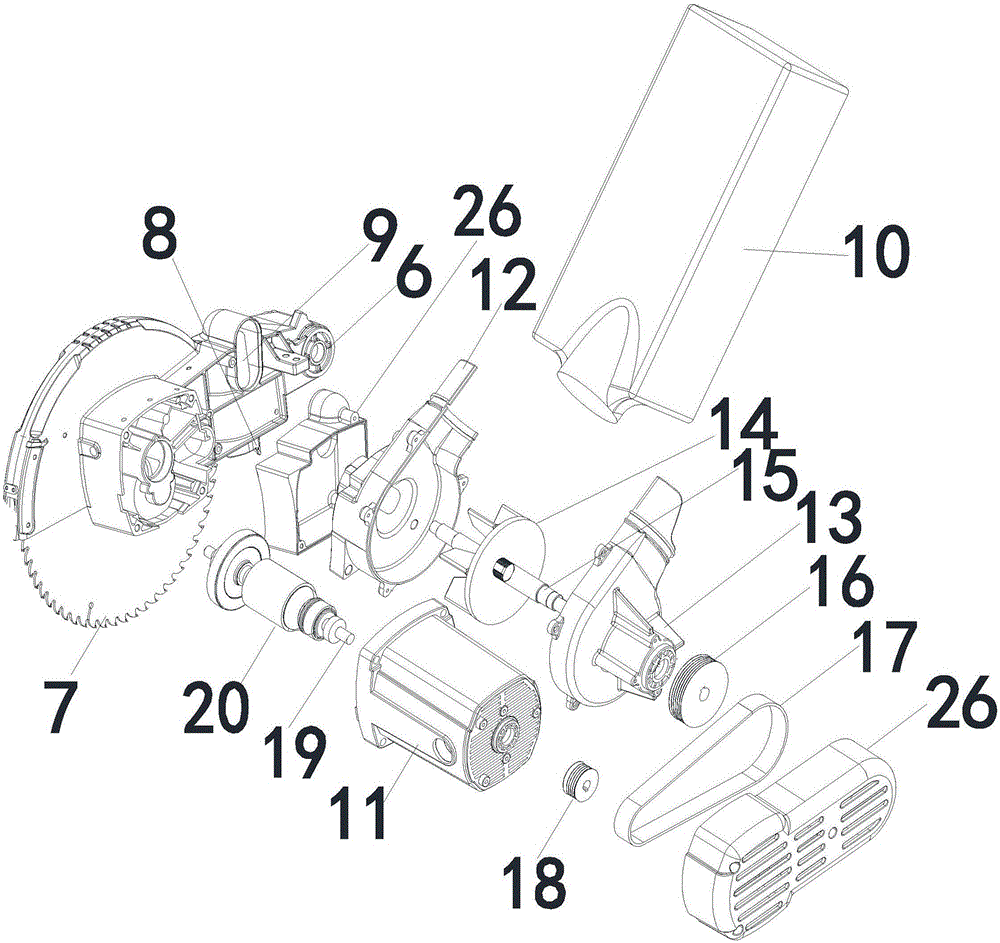

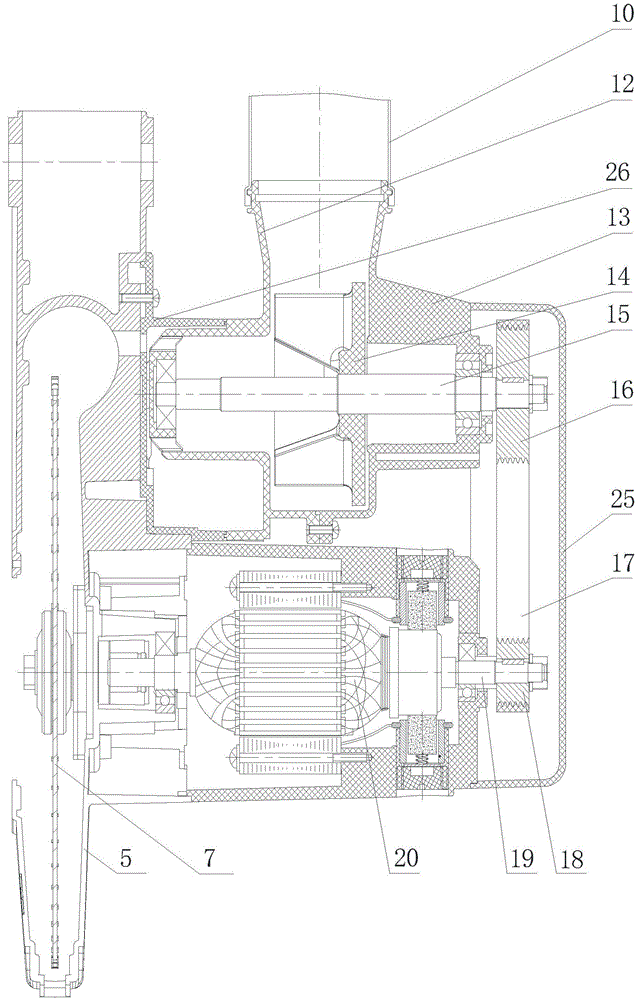

[0036] Such as Figure 1~4 As shown, a dust-free miter saw includes a base, a turntable is arranged on the base, a fence and a sliding part head are arranged on the turntable, a protective cover is provided on the sliding part head, a knife cover is arranged inside the protective cover, and a knife cover is arranged inside the protective cover. The cover is connected with the handle, the inside of the knife cover is the saw blade, the knife cover dust block is set on the knife cover in front of the saw blade rotation direction, the knife cover dust outlet is arranged above the knife cover dust block, the knife cover dust outlet is connected with the suction The dust collecting device is connected, the dust collecting device is connected with the dust collecting bag, a motor is arranged on the side of the dust collecting device, and the motor simultaneously drives the saw blade and the dust collecting device.

[0037] Such as figure 2 As shown, the dust suction device in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com