Non-manual liner corner trimming mechanical device

A kind of mechanical equipment and non-artificial technology, which is applied in the field of non-artificial liner corner trimming machinery and equipment, can solve the problems of complex equipment mechanism, inaccurate cutting thickness, low production efficiency, etc., and achieve smooth operation, low working noise and excellent structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

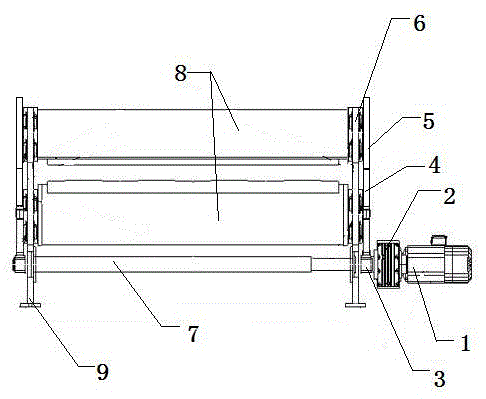

[0014] This embodiment provides a non-artificial liner corner trimming mechanical device, characterized in that: the non-artificial liner corner trimming mechanical device includes a motor (1), a reducer (2), and a driving gear (3) , Driven gear A (4), driven gear B (5), side plate (6), main shaft (7), upper and lower blade mounting frame (8), bracket (9);

[0015] Wherein: it includes support (9), the left and right side plates (6) that are installed on the support (9) on both sides, the upper and lower blade mounting frames (8) fixed on the left and right side plates (6), the lower blade mounting frame (8) ) is connected to the left and right side plates (6) through the axle drive of the driven gear A (4), and the upper blade mounting frame (8) is connected to the left and right side plates (6) through the axle drive of the driven gear B (5). The upper and lower blade mounting brackets (8) are equipped with upper and lower blades, the lower ends of the left and right side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com