Procedure heat treatment technique of soft aluminum alloy for anodic oxidation

An anodic oxidation and aluminum alloy technology, applied in the field of aluminum alloy processing, can solve the problems of high investment risk and stagnant pace of 1090 high-end anodic oxidation materials, and achieve the effect of high forming capacity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The 1090 soft aluminum alloy plate ingot is homogenized at a low temperature of 450°C and held for 8 hours; then it is rolled at a low temperature of 410-430°C, and the final rolling temperature of the hot rolling is controlled at a specific temperature range of 235-250°C, and natural aging is adopted. Method After 48 hours of temporary storage, cold rolling is carried out. First, three passes of semi-finished product production are carried out using high-roughness textured work rolls with a roughness of 0.55-0.65 μm, and then two passes are carried out with low-roughness work rolls with a roughness of 0.35-0.38 μm. For the next finished product rolling, cleaning is carried out after the cold rolling is completed. The cleaning needs to be completed within 48 hours. The cleaned product is annealed in an ordinary air annealing furnace. Start timing at ℃, keep warm for 8 hours, and use air cooling to cool after keeping warm.

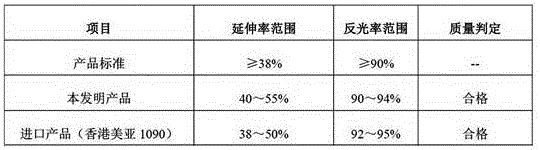

[0032] After the 1090 soft aluminum alloy plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com