Metal connector for improving integrity of rammed-earth wall structure and rammed-earth wall structure

A technology of metal connectors and rammed earth walls, applied to building components, walls, building structures, etc., can solve the problems of inconspicuous actual effects and achieve improved shear resistance, integrity, good integrity and shear resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

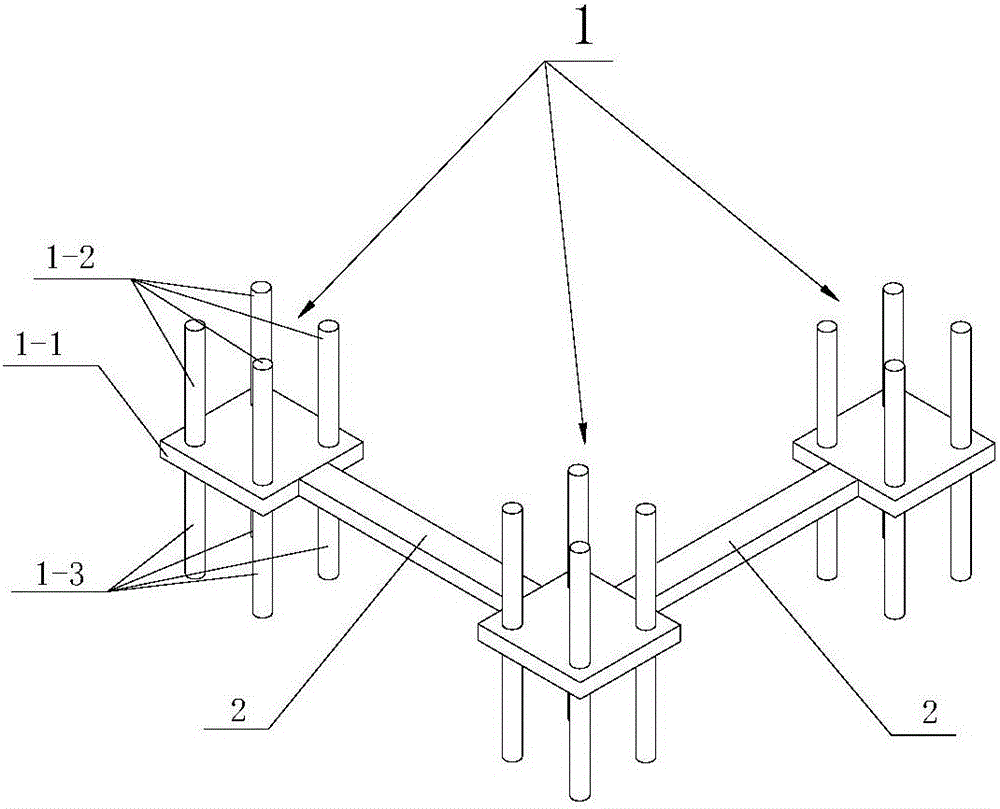

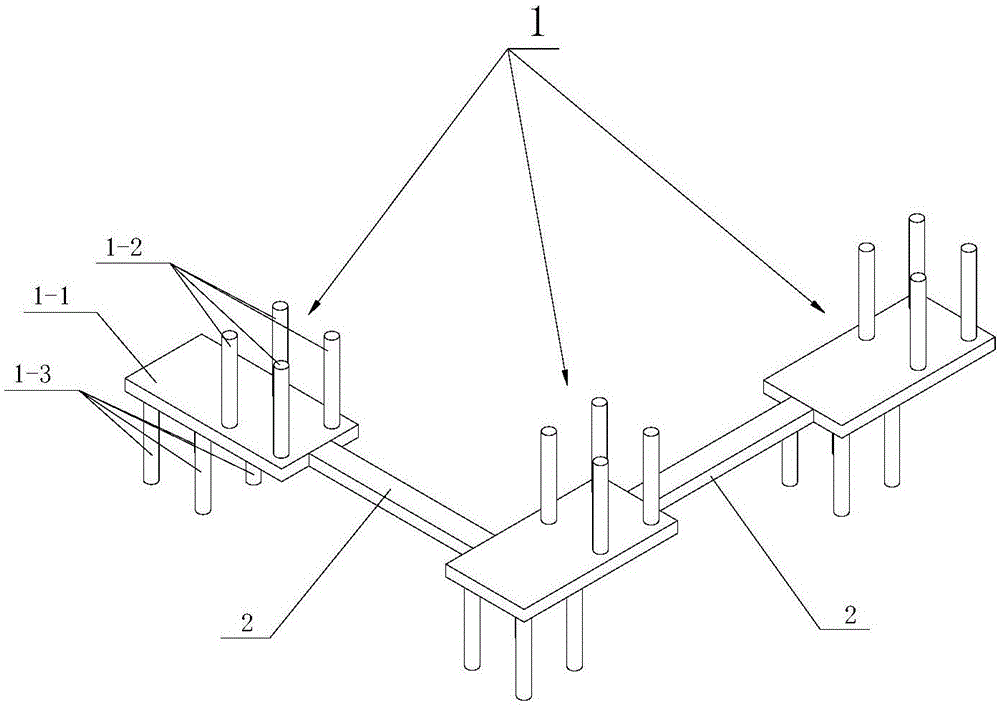

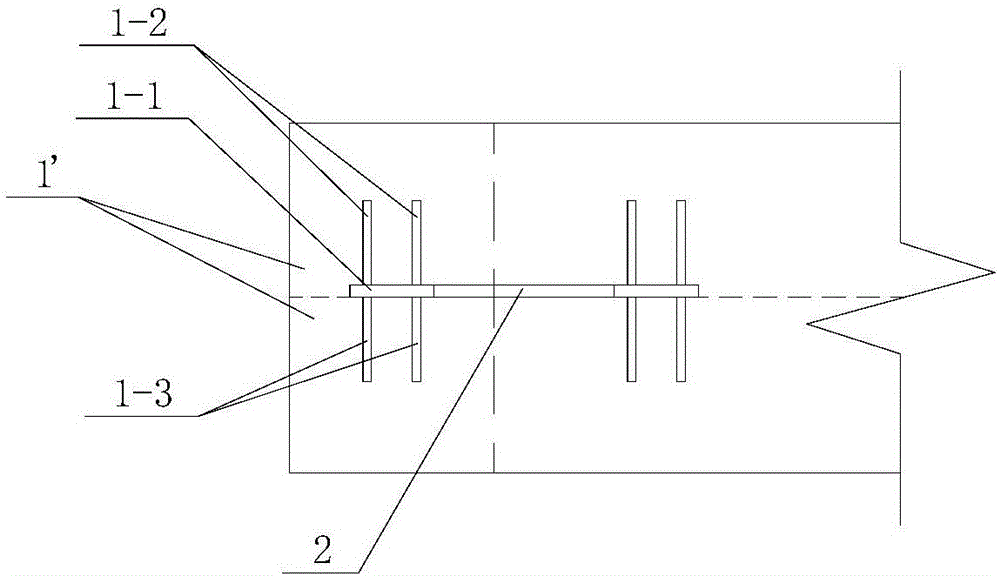

[0029] See Figure 1-2 , the metal connector used to improve the structural integrity of the rammed earth wall, the metal connector includes a group of shear units 1, each group of shear units consists of a steel plate 1-1 located in the middle, and a plurality of upper anti-corrosion plates welded vertically to the upper end of the steel plate. The shear steel column 1-2 is composed of a plurality of lower shear steel columns 1-3 vertically welded to the lower end of the steel plate, the shape of the steel plate, the number of the upper shear steel column, the number of the lower shear steel column, the upper shear steel column The arrangement of the columns and the arrangement of the lower shear steel columns are not restricted. The groups of shear units form an integrated connection structure through the connecting steel pieces 2 welded between the steel plates, and are L-shaped (also called L-shaped) in the horizontal direction.

[0030] In the metal connector structure o...

Embodiment 2

[0039] See Figure 5-6 , the metal connectors in this embodiment include the shear units described in the first embodiment above and the connecting steel parts arranged between the shear units. The difference from the first embodiment is that the array of shear units is welded The connecting steel pieces form an integrated connection structure, and it is T-shaped in the horizontal direction.

[0040] In the metal connector structure of the second embodiment, the shape of the steel plate, the number of the shear steel columns and the preferred arrangement of the shear steel columns are the same as those of the first embodiment, and will not be repeated here.

[0041] In the metal connector structure of the second embodiment, the preferred structure of the upper shear steel column and the lower shear steel column and the preferred structure of the connecting steel parts are the same as those of the first embodiment, and will not be repeated here.

[0042] Embodiment 2 In the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com