Deflecting plate jet flow electro-hydraulic servo valve based on piezoelectric structure

A piezoelectric structure and deflection plate technology, applied in servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of oil leakage of connecting rods and reaction rods, and achieve good dynamic performance, simple structure, high frequency Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

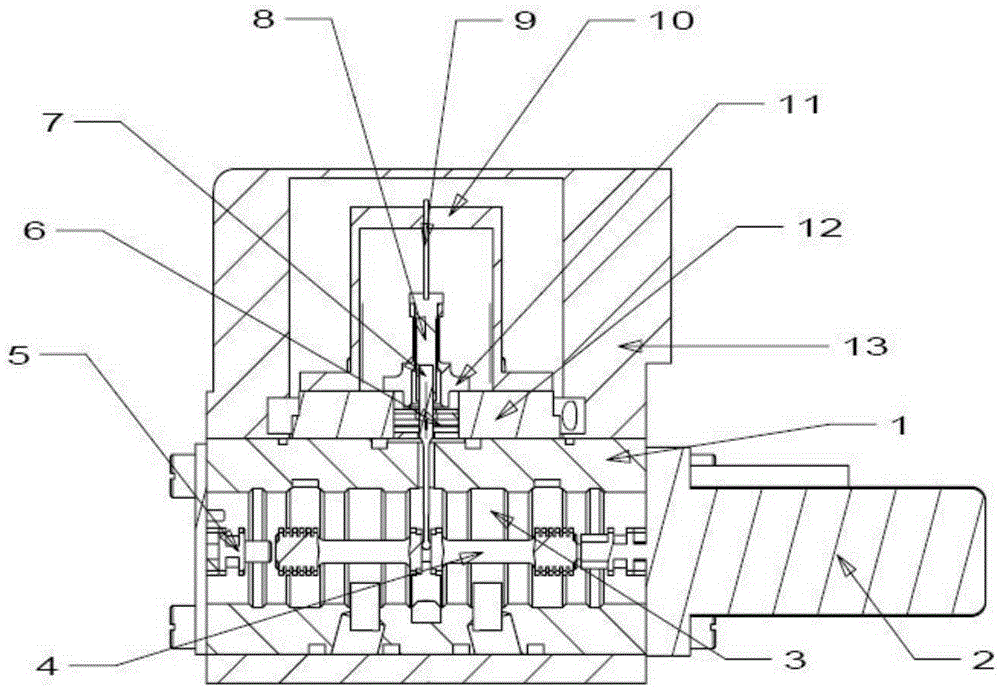

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] The structure of the present invention mainly includes structures such as a valve body, a valve sleeve, a valve core, a sensor, a piezoelectric chip, a spring tube, a reaction force rod, and a connecting rod. The first section of the piezoelectric bimorph is assembled in the middle of the support structure by means of press-fit connection, the end is connected with the connecting rod by press-fit, the connecting rod is respectively connected with the spring tube and the reaction rod through press-fit, and the support structure and the spring tube are installed by screws On the upper shell, the jet component is installed inside the upper shell, which forms a jet structure together with the narrow groove in the reaction rod; the sensor is connected to the end surface of the valve body, the valve sleeve and the valve core are installed inside the valve body, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com