Buffering hydraulic cylinder

A buffering hydraulic cylinder and buffering spring technology, applied in the field of buffering hydraulic cylinders, can solve the problems of deformation of the hydraulic cylinder wall and piston, affecting the service life, deforming the cylinder body, etc., to reduce non-axial force, improve heat dissipation efficiency, avoid effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

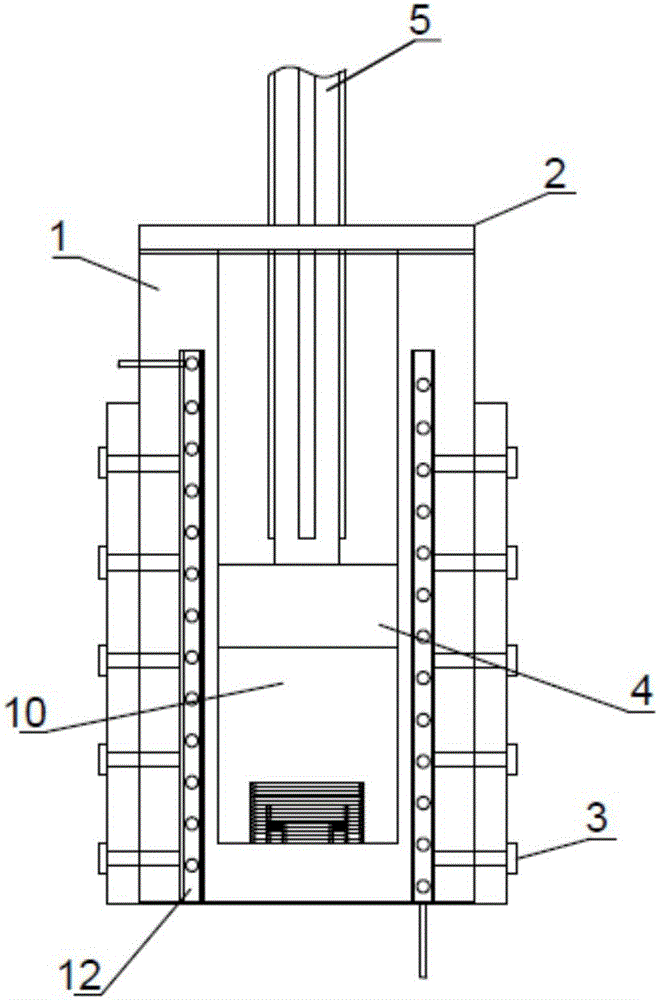

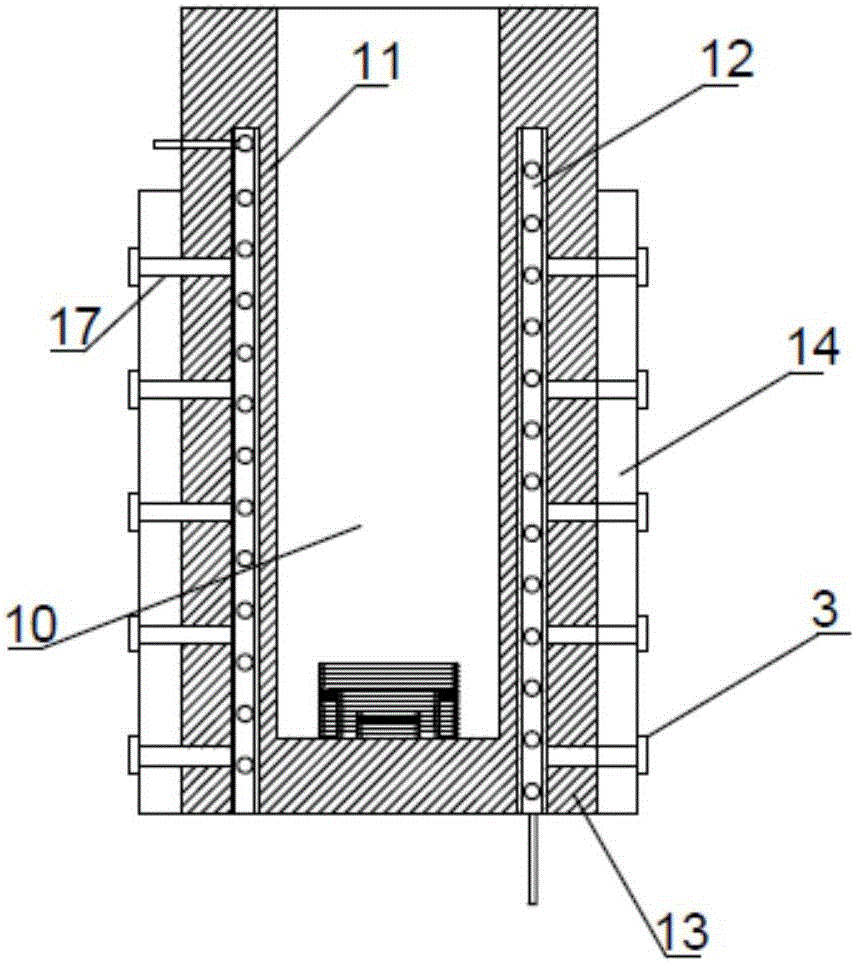

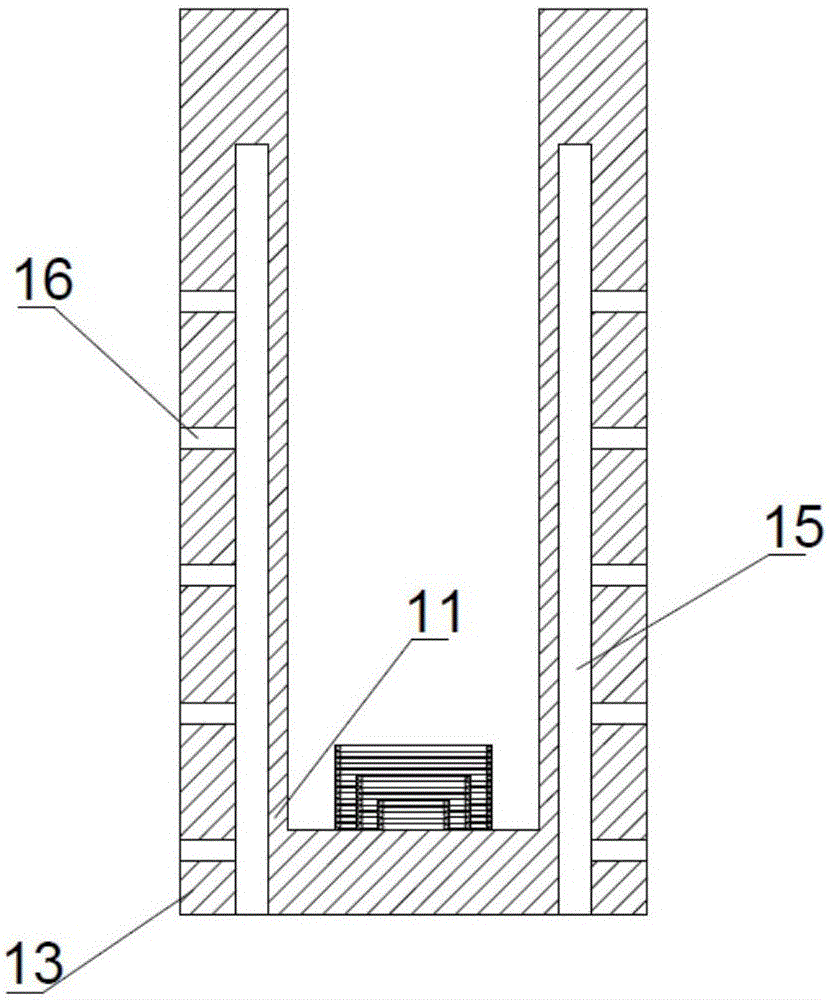

[0019] Such as Figure 1-6 As described above, this embodiment provides a buffer hydraulic cylinder, including a cylinder body 1, a cylinder head 2, a hollow bolt tube 3, a piston 4, and a piston rod 5; the bottom of the piston rod 5 is connected to the piston 4; the cylinder body 1 is a metal cylindrical structure, one end of which is provided with a cylinder head 2; the cylinder body 1 is sequentially composed of a cavity 10, a cylinder inner wall 11, a water cooling device 12, a cylinder outer wall 13 and a heat dissipation device 14 from the inside to the outside; the water cooling device 12 Installed in the annular slot 15 between the cylinder inner wall 11 and the cylinder outer wall 13; the water cooling device 12 is a cylindrical structure, including an inner cylinder 21, an outer cylinder 22 and a spiral water cooling tube 23; the spiral water cooling tube 23 Installed between the inner cylinder 21 and the outer cylinder 22; the two ends of the spiral water cooling pi...

Embodiment 2

[0021] Such as Figure 1-6 As shown, this embodiment provides a buffer hydraulic cylinder, different from Embodiment 1, the side wall of the piston rod 5 is provided with an outwardly protruding positioning bar; the top of the cylinder head 2 is provided with a plurality of annular heat sink.

Embodiment 3

[0023] Such as Figure 1-6 As shown, this embodiment provides a buffer hydraulic cylinder, different from Embodiment 2, the buffer device includes three buffer springs, the first buffer spring 31 with the largest diameter, the second buffer spring 32 and the first buffer spring with the smallest diameter Three buffer springs 33; the first buffer spring 31, the second buffer spring 32 and the third buffer spring 33 are concentrically arranged, and the diameter and height gradually decrease from the outside to the inside; the first buffer spring 31, the second buffer spring 32 and the third buffer spring The height ratio of the buffer spring 33 is 3:2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com