Rapidly-mounted and rapidly-dismounted multifunctional combined support capable of being repeatedly used

It is a multi-functional combination and quick-installation technology, which is applied to pipeline supports, measuring devices, and engine testing. It can solve the problems of difficult to guarantee safety, uncivilized operation methods, and pipeline shaking, etc., and achieve a simple and practical structure and a simple and elegant appearance. , The effect of easy and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

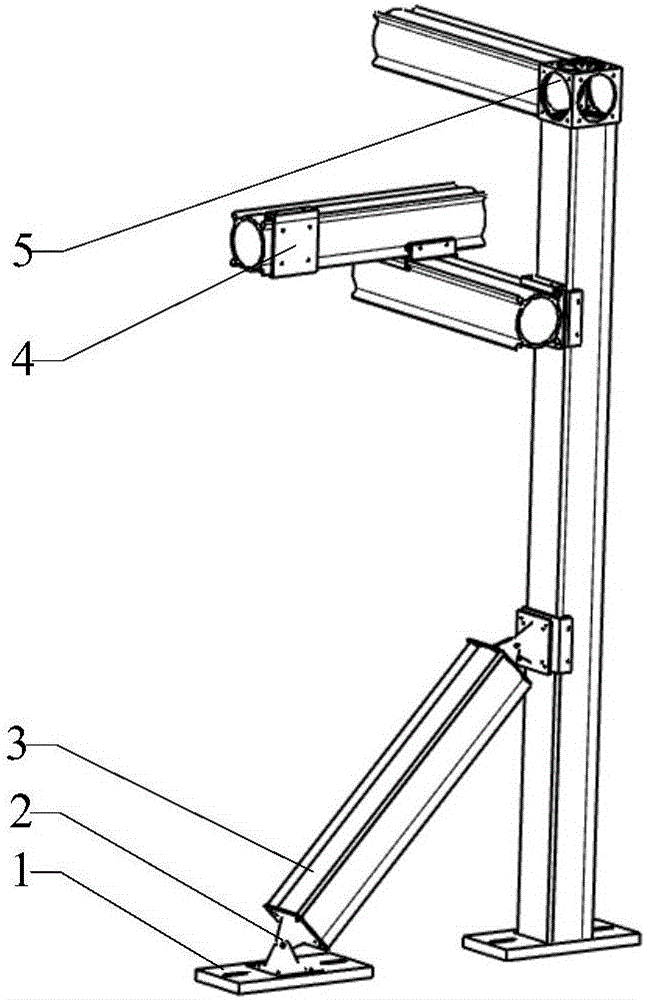

[0026] The multifunctional combined bracket includes a bottom plate 1, a rotating seat 2, a cross hollow beam 3, a card seat 4 and a six-sided adapter seat 5.

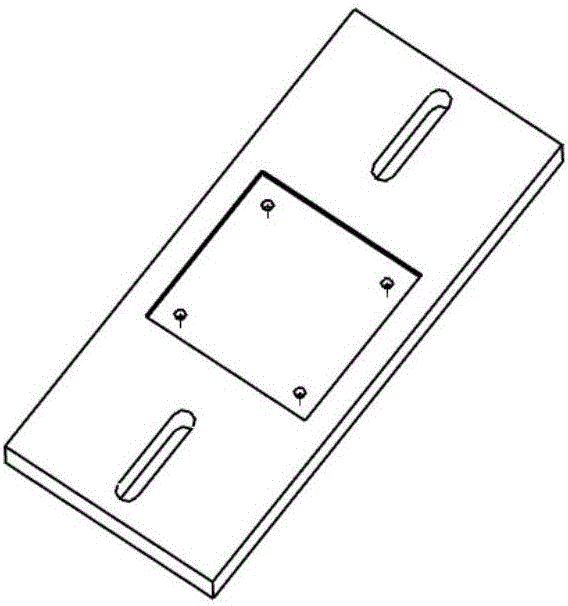

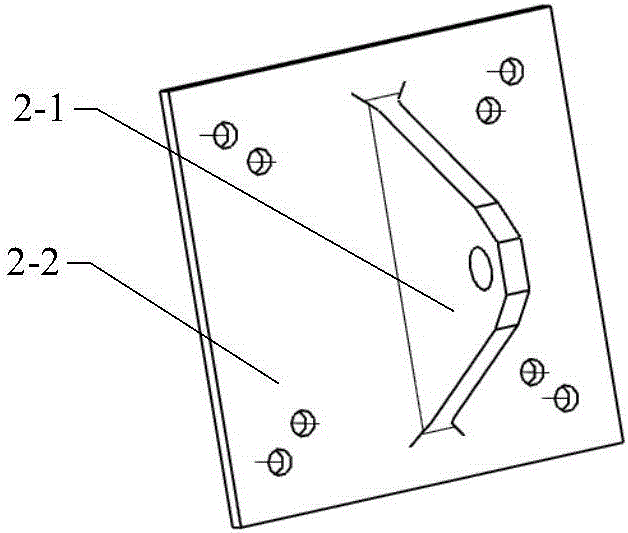

[0027] The lower plane of the bottom plate 1 is fixedly connected with the stand through strip holes, and the upper plane of the bottom plate 1 can be connected with the swivel seat 2 or the cross hollow beam 3 respectively through four bolt connection holes; The shaft pins are connected together at a certain angle, and the bottom surface of the swivel seat 2 can be connected with the bottom plate 1 or the cross hollow beam 3 respectively through four bolt connection holes; the middle of the cross hollow beam 3 is a hollow cylindrical cylinder 3-2, which is symmetrical on all four sides Four completely symmetrical ribs 3-1 are arranged, and threaded holes are provided at the root attachments of each rib. The cross hollow beam 3 can be connected with the bottom plate 1 and the six-sided adapter seat 5 respectively throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com