Monitoring device and method for piston torque of rubber membrane seal gas holder

A monitoring device and sealing gas technology, which is applied in the direction of adjustable capacity gas storage tanks, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of falling, inaccurate measurement data, poisoning, etc., to improve production safety, Prevents the effect of the abnormal state of the piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

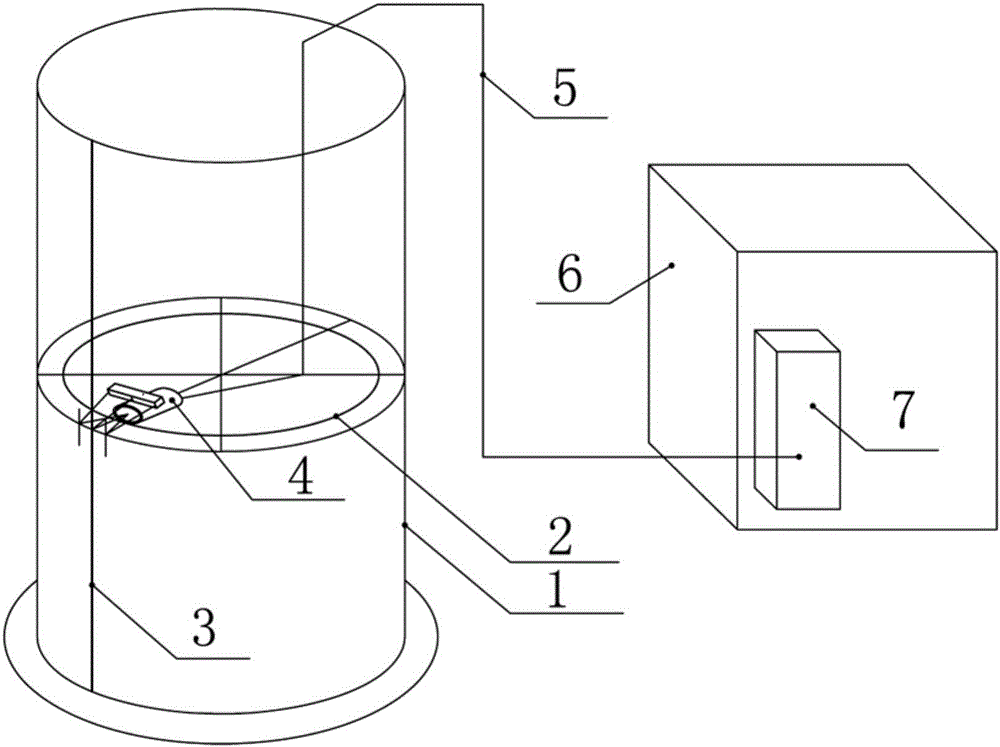

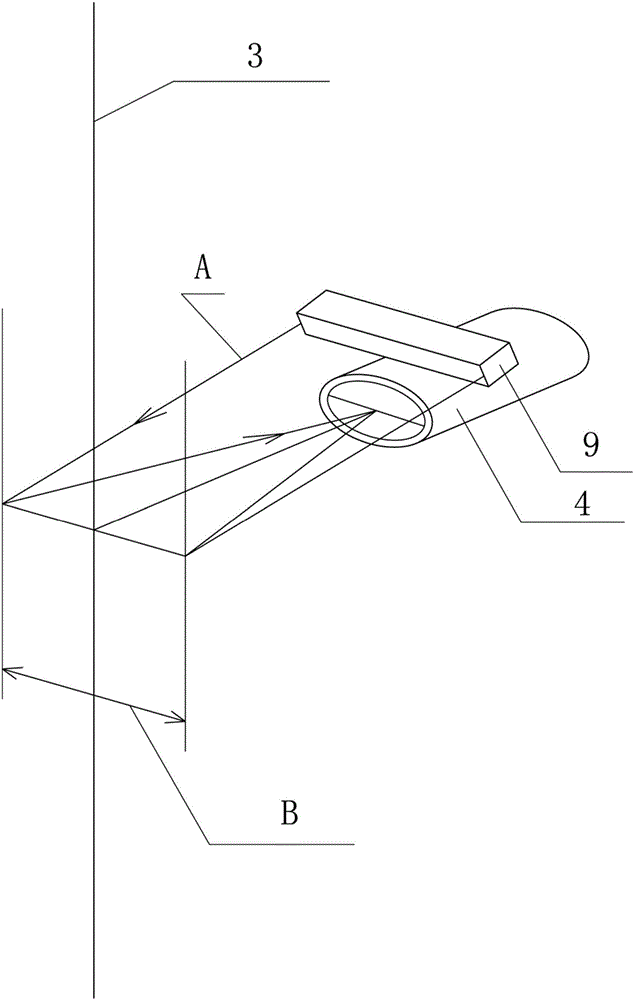

[0034] Embodiment 1: as Figure 8 As shown, the explosion-proof torsion probe 4 is externally equipped with an explosion-proof light source 9 to supplement the lack of light in the gas cabinet. A vertical reference line 3 is provided from top to bottom in the side wall of the gas cabinet 1. The color of the vertical reference line 3 is clearly distinguished from the background color of the inner wall of the gas cabinet 1, which is convenient for image analysis and processing of the explosion-proof torsion probe 4. The width of the line is It can be about 5-10mm; the distance measuring circuit is installed in the explosion-proof torsion probe 4, and the distance between the position of the explosion-proof torsion probe 4 and the side wall of the gas cabinet 1 is obtained, and the offset result is corrected by using this distance value; the distance measurement circuit can use : Laser ranging, ultrasonic, infrared, radar, etc.

Embodiment 2

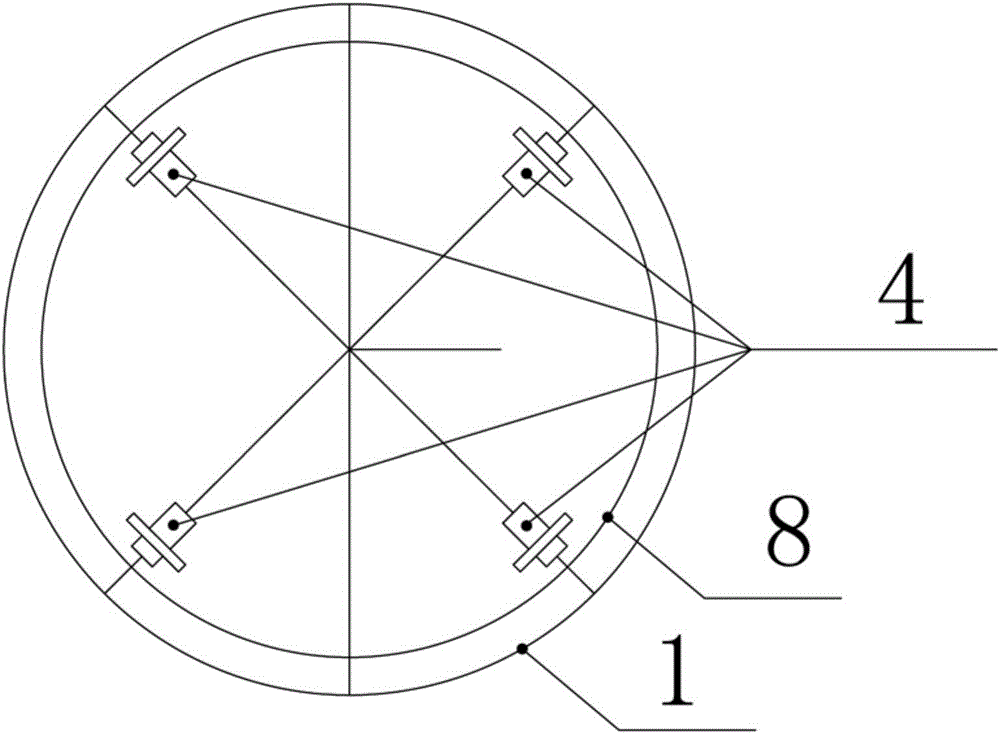

[0035] Embodiment 2: as image 3 and Figure 9 As shown, the explosion-proof torsion probe 4 is externally equipped with an explosion-proof light source 9 to supplement the lack of light in the gas cabinet. Two vertical reference lines 3 are arranged from top to bottom in the side wall of the gas cabinet 1. The color of the vertical reference lines 3 is clearly distinguished from the background color of the inner wall of the gas cabinet 1, which is convenient for the image analysis and processing of the explosion-proof torsion probe 4; the width of the lines It can be about 5-10mm; the image analysis software and displacement result processing software are slightly different from Embodiment 1. The explosion-proof torsion probe 4 automatically compensates and adjusts the result according to the actual width of the two vertical reference lines 3 and the obtained image width.

[0036] Such as figure 2 , Figure 6 and Figure 7As shown, the take-up reel A15: placed on the pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com