Product surface defect detection method

A defect detection and product technology, applied in the direction of optical defect/defect test, measuring device, image data processing, etc., can solve problems such as unreliability, unreliability, instability, etc., to reduce complexity, improve operating speed, The effect of increasing the processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

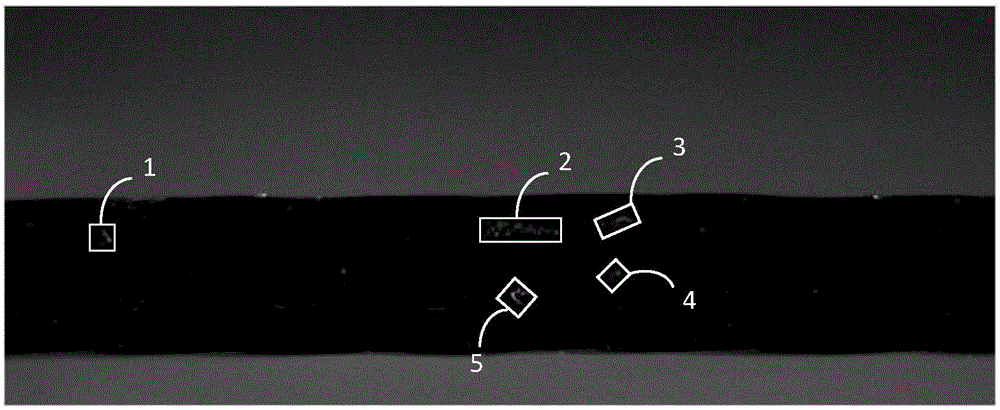

[0042] Taking the identification of surface defects of optical cables as an example, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0043] In the optical cable manufacturing process, the transmission speed of the optical cable is usually 1-2.5m / s. In order to ensure that all the defects on the surface of the optical cable are captured, the image frame rate needs to reach 100fps. Preferably, the present invention adopts 4 high-speed cameras installed in the four directions of up, down, left, and right of the optical cable at the same time, then the number of images to be processed in 1 second is 400 frames, and the processing time of each frame of images is 2.5ms.

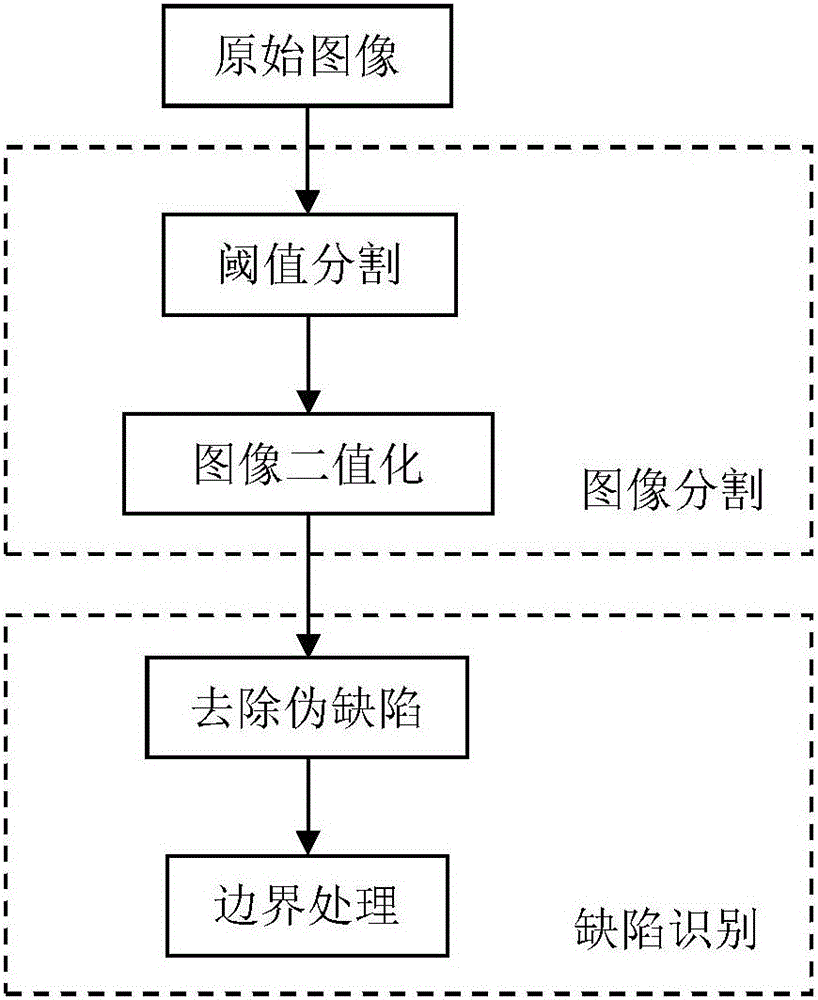

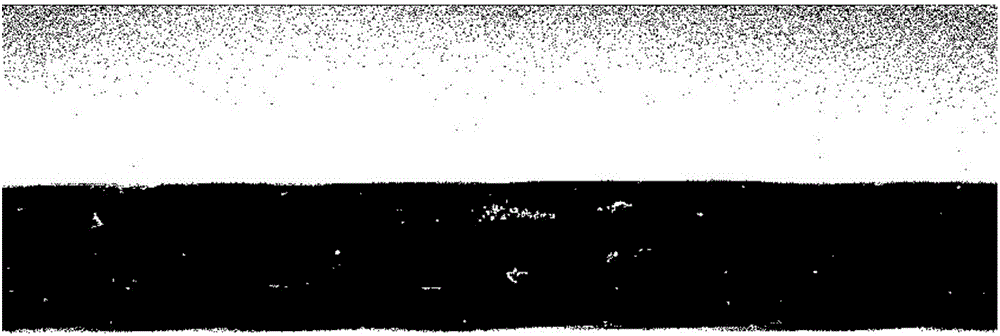

[0044] Therefore, the detection algorithm should not only ensure the detection accuracy but also meet the real-time requirements of the system. Considering the defect characteristics and real-time processing requirements of the capt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com