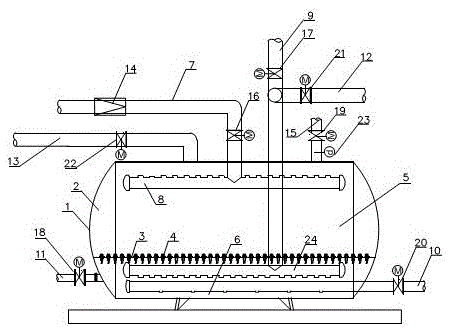

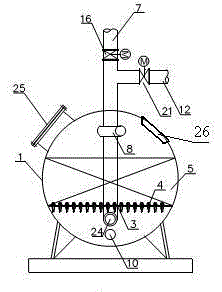

Automatic graded filtering tank device

An automatic classification and filter tank technology, which is applied in the direction of filtration and separation, membrane filter, gravity filter, etc., can solve the problems of easy hardening of filter material, small filter area, easy mixing layer of filter material, etc., and achieve the increase of dirt holding capacity , extend the filtration cycle, increase the effect of the filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] like figure 1 and figure 2 As shown, the tank body 1 is arranged horizontally, with heads 2 provided at both ends, and a manhole 25 and an observation hole 26 are arranged on the side of the tank body 1. On the upper part of the tank body 1, the water inlet pipe flowmeter 14 and the The water pipe electric valve 16 is arranged on the water inlet pipe 7 . The inside of the filter tank is provided with a water distribution pipe 8, the water distribution pipe 8 is provided with a water distribution pipe orifice, and the water distribution pipe orifice is opened upwards. In the upper part of the tank, a water collection pipe 24 is also provided inside the filter tank. The water pipe 24 is provided with a water collection pipe aperture, and the water collection pipe aperture downwards offers, and in the bottom in the tank, the water distribution pipe 8 links to each other with the water inlet pipe 7. The filter plate 3 divides the filter tank into an upper filter area and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com