Device and method for detecting liquidity of liquid casting powder

A detection device and detection method technology, applied to the configuration of indicating equipment/measuring equipment, manufacturing tools, casting equipment, etc., can solve the problems of long measurement cycle, insufficient rigor, no evaluation method for fluidity, etc., and achieve fast detection speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

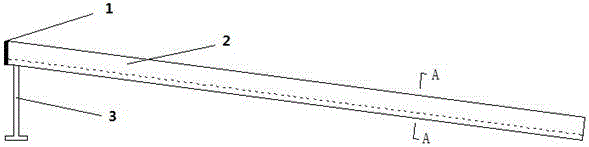

[0053] Detection of an ultra-low carbon steel (liquidus temperature T ll =1532℃) with the fluidity of mold flux A. The length of the chute used is not less than 105cm, the inclination angle is 10°, the cross section of the chute is V-shaped, and the included angle of the V-shape is 90°;

[0054] The specific steps of the high temperature fluidity test are:

[0055] (1) Bake 150g of finished mold flux in a SiC wide-mouth container at a constant temperature of 700°C for 2 hours;

[0056] (2) Weigh 50g of the slag sample after complete burning, put it in a high-purity graphite crucible, and keep it in a high-temperature furnace at 1350°C for 15 minutes;

[0057] (3) Quickly take the graphite crucible out of the high-temperature furnace with tongs, and pour the molten slag onto the end of the launder with a plug at one time;

[0058] (4) The liquid slag flows down along the launder and gradually solidifies, and the measured length of the formed slag is 42cm.

[0059] The speci...

Embodiment 2

[0065] Detect a medium carbon steel (liquidus temperature T ll =1520℃) with the fluidity of mold flux B. The length of the chute used is not less than 105cm, the inclination angle is 10°, the cross section of the chute is V-shaped, and the included angle of the V-shape is 90°;

[0066] The specific steps of the high temperature fluidity test are:

[0067] (1) Bake 150g of finished mold flux in a SiC wide-mouth container at a constant temperature of 700°C for 2.5 hours;

[0068] (2) Weigh 50g of the slag sample after complete burning, put it in a high-purity graphite crucible, and keep it in a high-temperature furnace at 1350°C for 15 minutes;

[0069] (3) Quickly take the graphite crucible out of the high-temperature furnace with tongs, and pour the molten slag onto the end of the launder with a plug at one time;

[0070] (4) The liquid slag flows down along the launder and gradually solidifies, and the measured length of the formed slag is 84cm.

[0071] The specific step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com