Screening waste plastic shredder

A technology of waste plastics and shredders, which is applied in plastic recycling, mechanical material recycling, grain processing, etc. It can solve the problems of prolonging operation time, increasing viscosity, and increasing follow-up steps, so as to improve crushing quality, uniform waste plastics, and reduce The effect of next steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

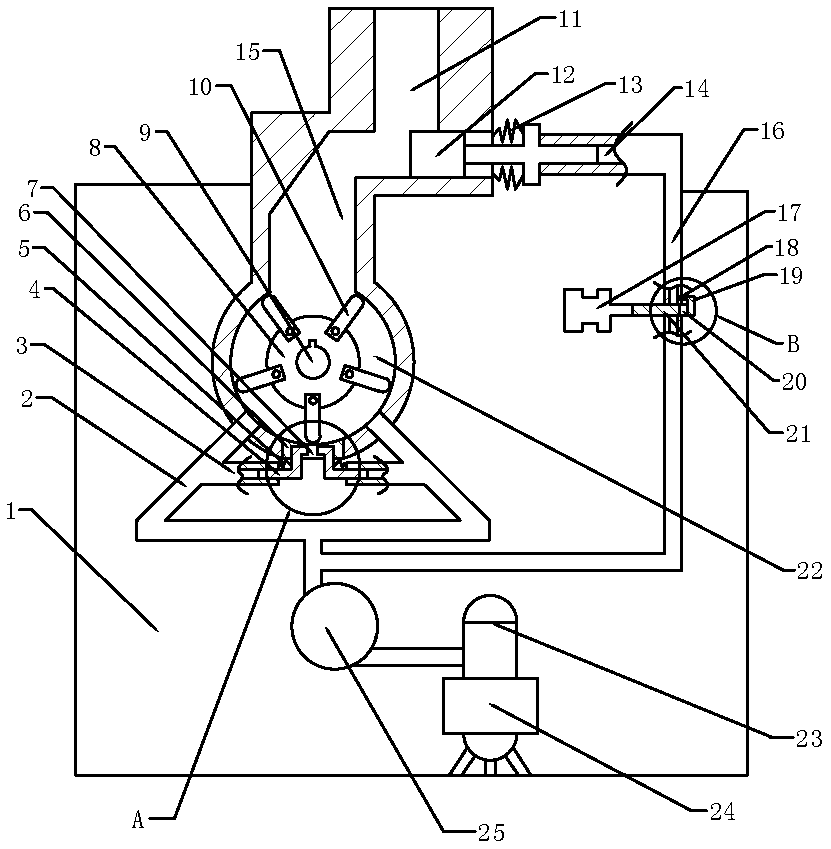

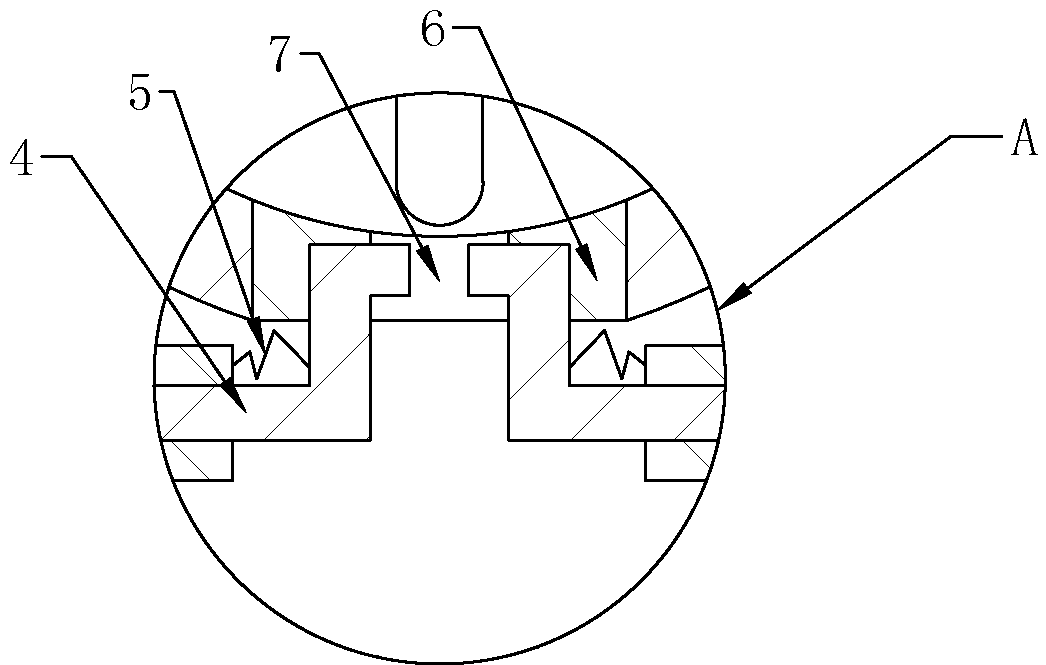

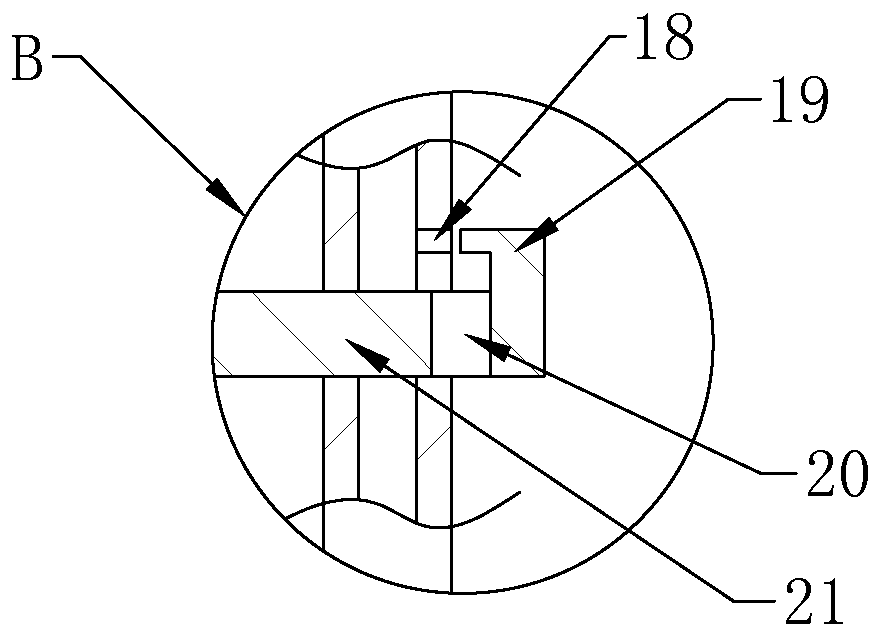

[0019] The reference signs in the drawings of the description include: frame 1, first ventilation pipe 2, regulating pipe 3, regulating plate 4, first spring 5, cover 6, opening 7, turntable 8, rotating shaft 9, breaker 10, Feeding pipe 11, push block 12, second spring 13, output pipe 14, feeding channel 15, intermittent air pipe 16, cylinder 17, through hole 18, insert rod 19, ventilation hole 20, connecting plate 21, crushing chamber 22 , Air storage tank 23, cooler 24, air pump 25.

[0020] Example figure 1 , figure 2 and image 3 As shown, the screening type waste plastic crusher includes a frame 1, a crushing chamber 22 is fixed on the frame 1 by bolts, the crushing chamber 22 is connected with a feeding channel 15, and the crushing chamber 22 is rotatably connected with a crushing device, and the crushing device Including rotating shaft 9 connected in the crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com