Rear-independent suspension swing arm mounting bracket assembly for automobiles

A technology of independent suspension and mounting bracket, which is applied to the suspension, the cantilever mounted on the pivot, vehicle components, etc., which can solve the problems of shortening the service life of the lower swing arm and damage to the lower swing arm, so as to save materials and reduce production costs , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be described clearly and completely below. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

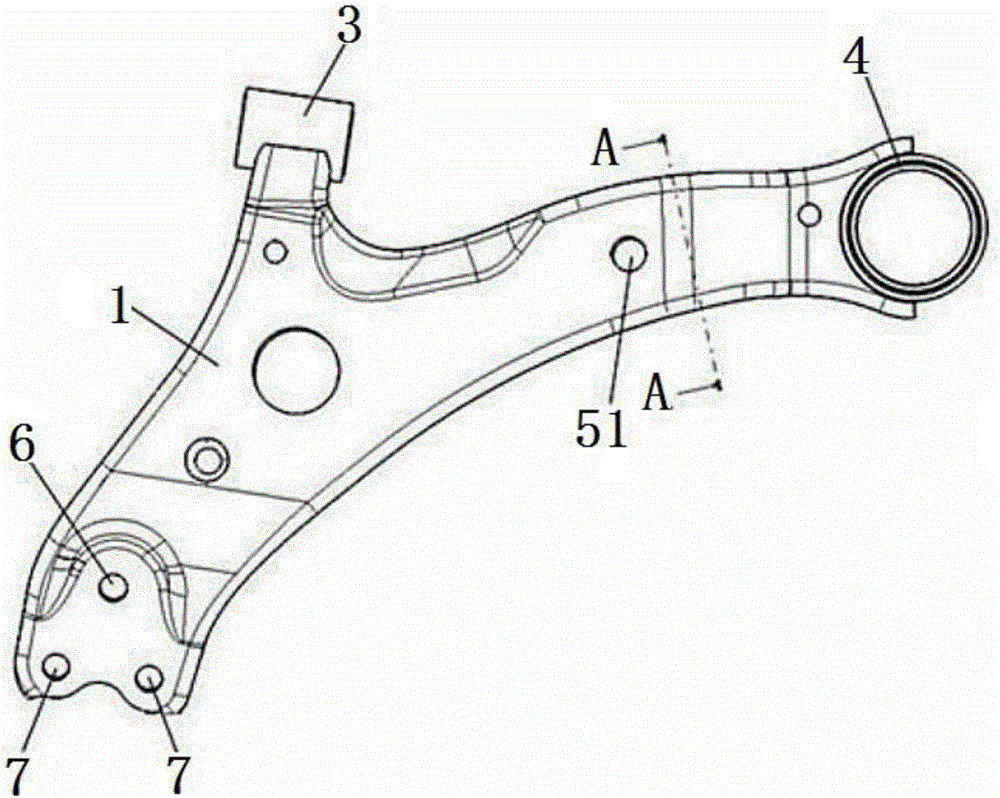

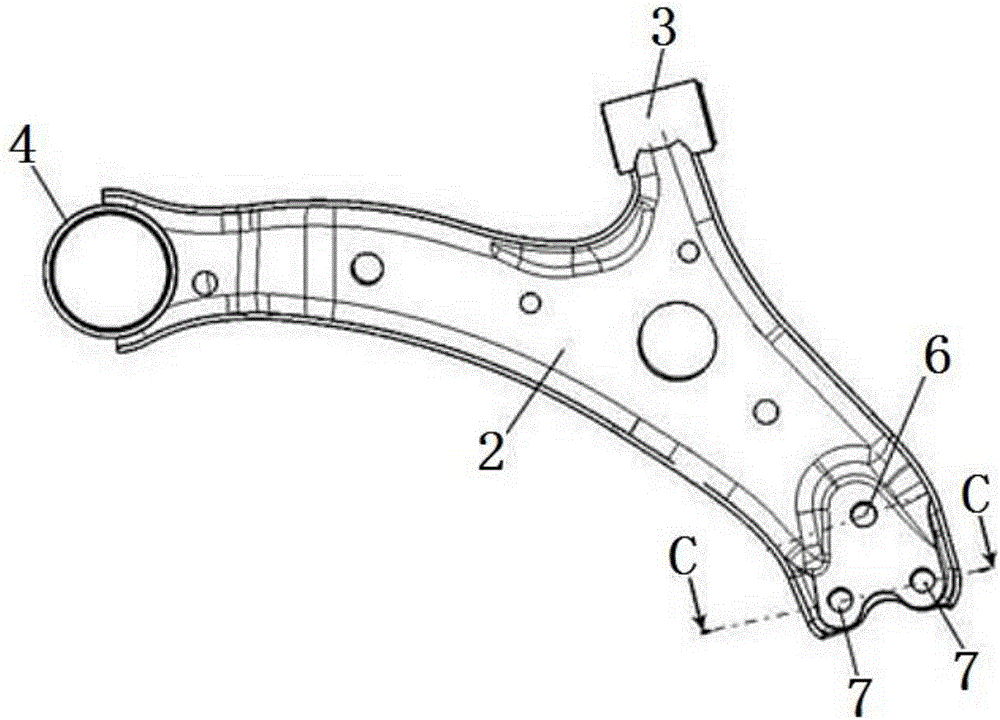

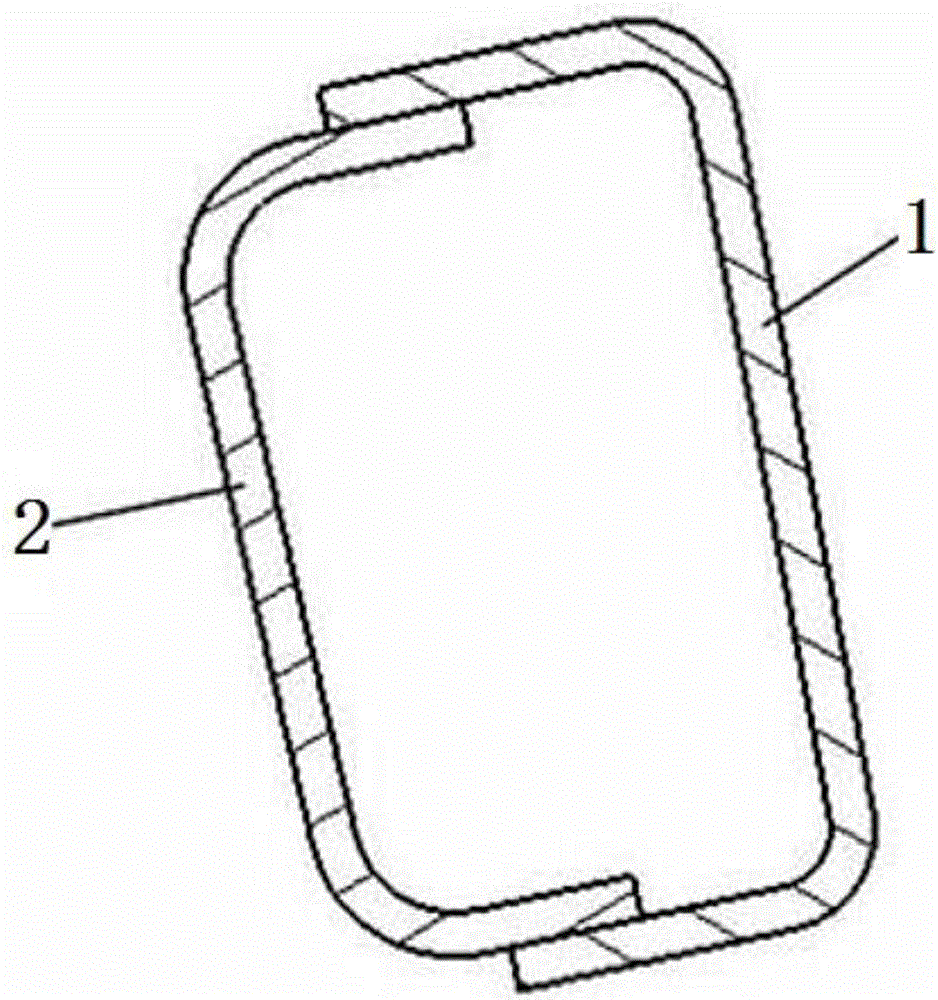

[0029] refer to Figure 5-8 , an automobile rear independent suspension swing arm mounting bracket assembly, comprising a swing arm body formed by butt welding an upper body 1 of a swing arm and a lower body 2 of the swing arm. The two ends and the middle part of the swing arm body are provided with connecting members, the connecting member at one end of the swing arm body is connected with the double ear hinge bracket of the vehicle body, the connecting member at the other end is connected with the rear suspension steering knuckle, and the connecting member in the middle is connected with the horizontal Stabilizer bar. The bottom of the swing arm body is covered with a rubber protective layer 9, the area covered by the rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com