Full electric vehicle multi-load high-voltage dc modular system

A pure electric vehicle, high-voltage DC technology, applied in the direction of electric vehicles, electric vehicle charging technology, circuits or fluid pipelines, etc., can solve the problems of poor scalability and cannot be reused, and reduce the burden, integration cost and time cost. , the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in conjunction with the accompanying drawings.

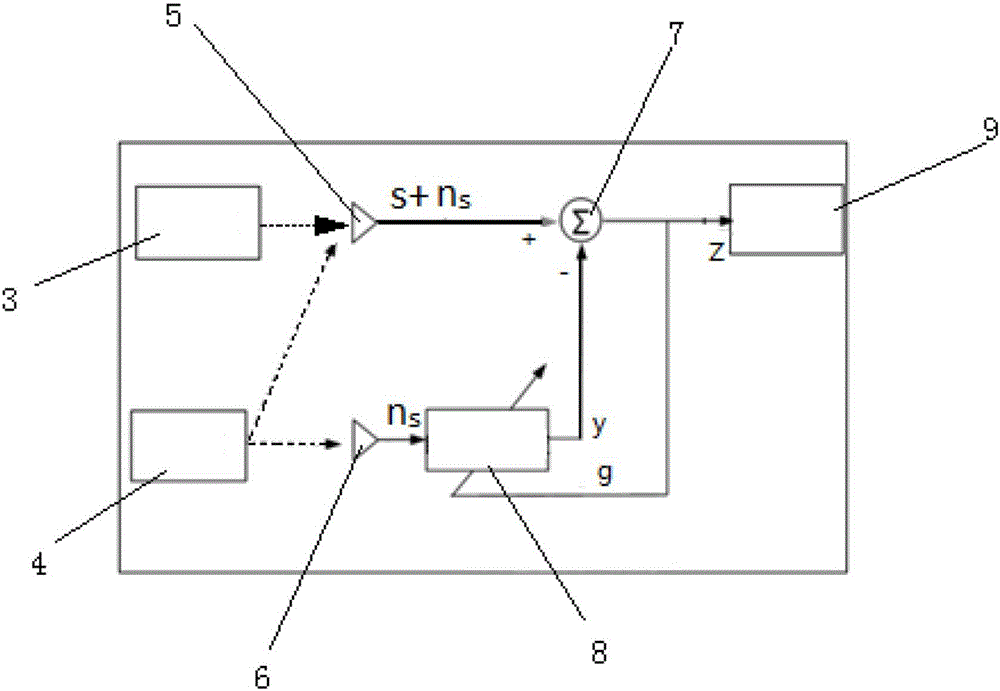

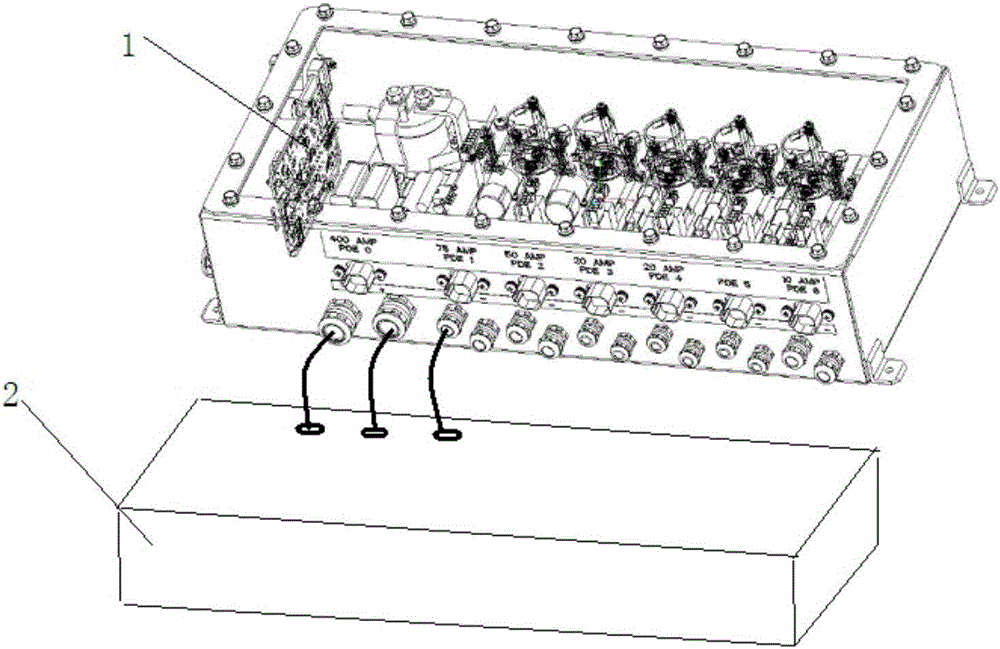

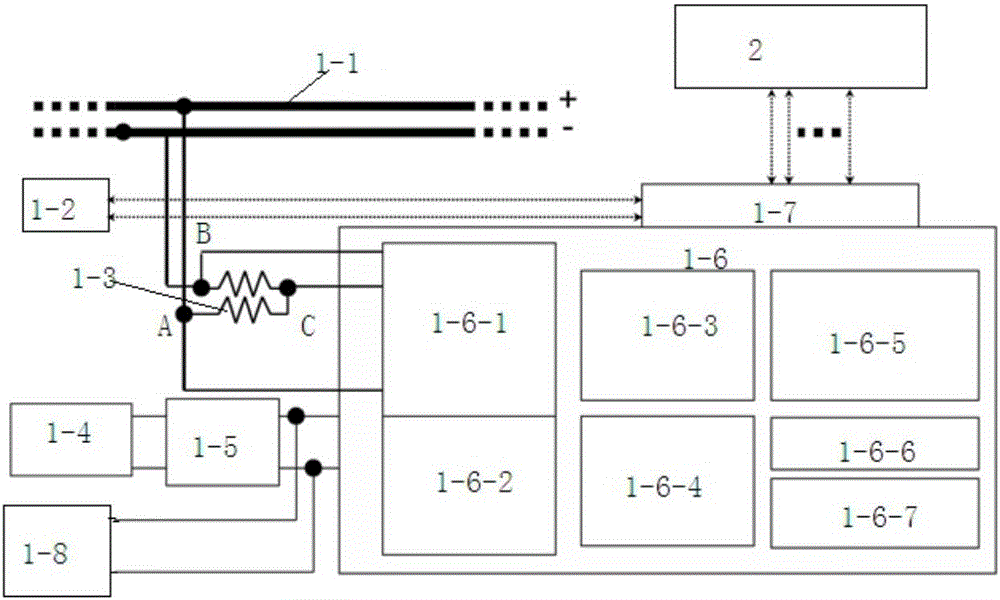

[0048] see Figure 1~Figure 7 , the present invention designs a multi-load high-voltage DC modular system for pure electric vehicles, including a central controller and vehicle loads, characterized in that: the central controller 1 is connected in parallel with the vehicle load 2; the central controller 1 is input by a high-voltage power supply to the bus 1-1. Vehicle HS CAN bus 1-2, voltage sensor 1-3, vehicle low-voltage power supply 1-4, low-voltage regulator 1-5, control CPU module 1-6 and communication interface 1-7, of which the control CPU module 1-6 consists of analog signal conditioning module 1-6-1, isolation fault diagnosis module 1-6-2, diagnosis and prediction module 1-6-3, user configuration table 1-6-4, power distribution module 1 -6-5, on-board diagnostic module 1-6-6 and safety function module 1-6-7, the fire wire of the high-voltage power supply input bus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com