Method and device for controlling DC bus voltage fault of vehicle

A DC bus voltage and DC bus technology, which is applied to electrical devices, vehicle components, collectors, etc., can solve the problem of rough security policies, reduced user driving experience, and greater impact on the driving experience of drivers and passengers on board, etc. Problems, to achieve the effect of ensuring driving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

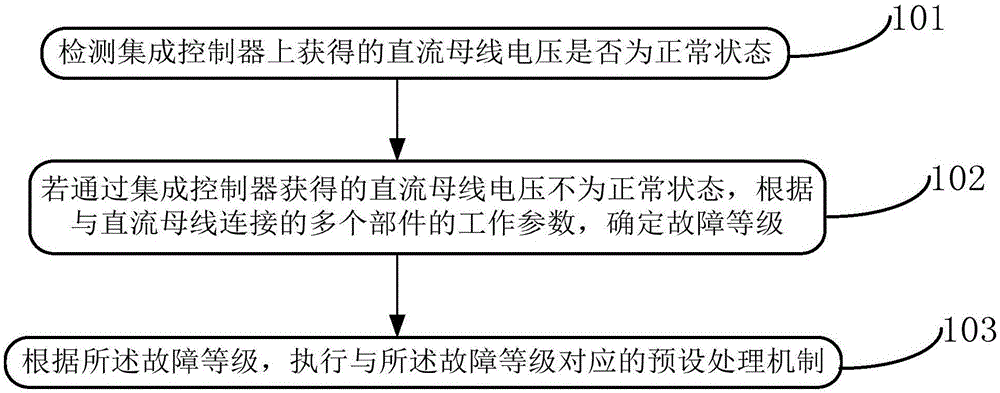

[0079] refer to figure 1 , an embodiment of the present invention provides a method for controlling a DC bus voltage failure of a vehicle, including:

[0080] Step 101, detecting whether the DC bus voltage obtained on the integrated controller is in a normal state;

[0081] Step 102, if the DC bus voltage obtained through the integrated controller is not in a normal state, determine the fault level according to the working parameters of multiple components connected to the DC bus;

[0082] Step 103, according to the failure level, execute a preset processing mechanism corresponding to the failure level.

[0083] Under normal conditions, the integrated controller directly obtains the voltage value on the DC bus and should be within a preset voltage range, and the integrated controller controls the components of the vehicle to work normally through the voltage value of the DC bus.

[0084] When it is detected that the DC bus voltage obtained directly by the integrated controll...

no. 2 example

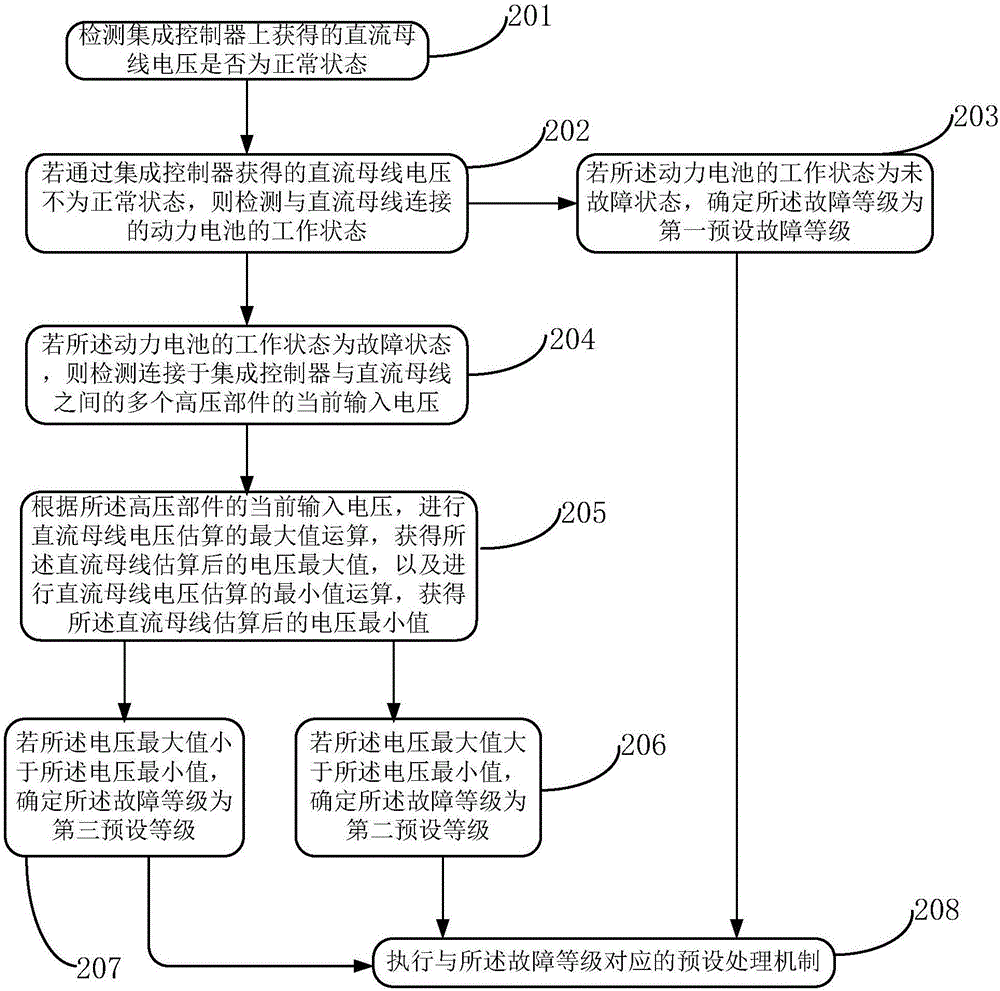

[0087] refer to figure 2 , the vehicle DC bus voltage fault control method provided by the second embodiment of the present invention includes:

[0088] Step 201, detecting whether the DC bus voltage obtained on the integrated controller is in a normal state;

[0089] Step 202, if the DC bus voltage obtained by the integrated controller is not in a normal state, then detect the working state of the power battery connected to the DC bus;

[0090] Step 203, if the working state of the power battery is not faulty, determine that the fault level is the first preset fault level;

[0091] Step 204, if the working state of the power battery is a failure state, then detect the current input voltage of a plurality of high-voltage components connected between the integrated controller and the DC bus;

[0092] Step 205, according to the current input voltage of the high-voltage component, perform the calculation of the maximum value of the estimated DC bus voltage to obtain the maximu...

no. 3 example

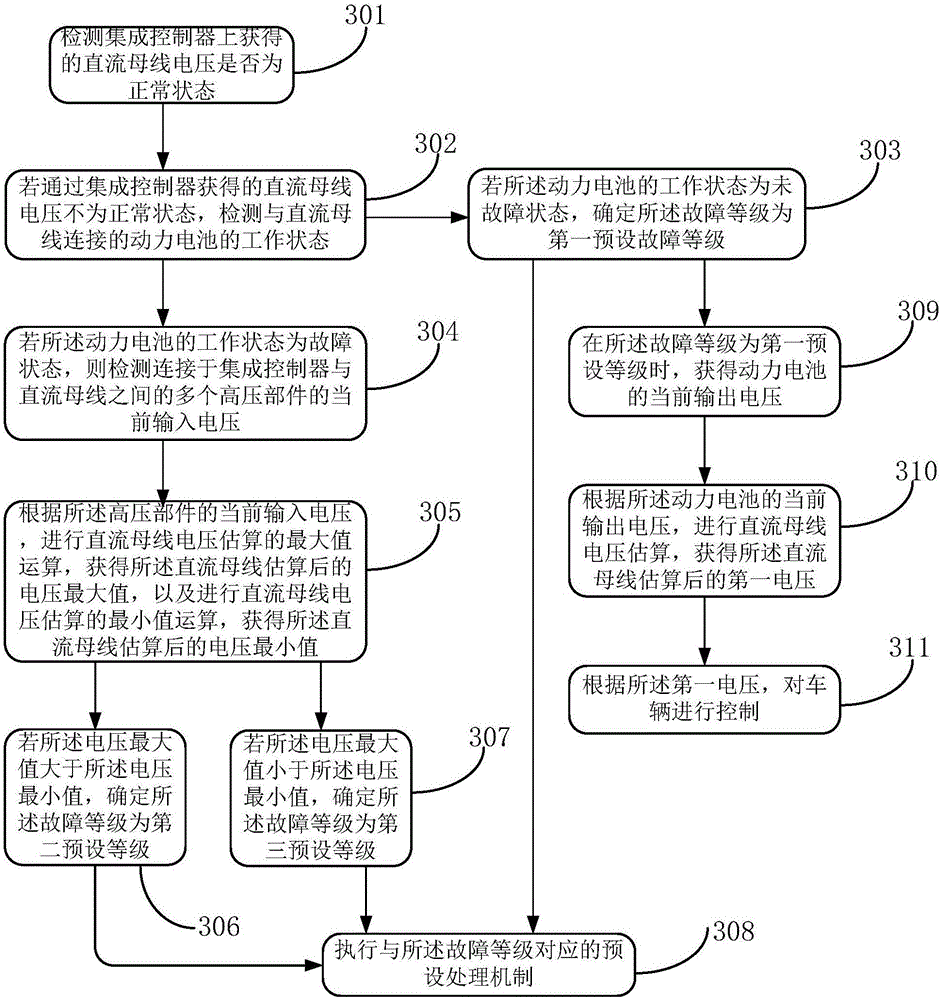

[0106] The third embodiment of the present invention provides a control method for vehicle DC bus voltage failure, including:

[0107] Step 301, detecting whether the DC bus voltage obtained on the integrated controller is in a normal state;

[0108] Step 302, if the DC bus voltage obtained by the integrated controller is not in a normal state, detect the working status of the power battery connected to the DC bus;

[0109] Step 303, if the working state of the power battery is not faulty, determine that the fault level is the first preset fault level;

[0110] Step 304, if the working state of the power battery is a failure state, then detect the current input voltage of multiple high-voltage components connected between the integrated controller and the DC bus;

[0111] Step 305, according to the current input voltage of the high-voltage component, perform the calculation of the maximum value of the estimated DC bus voltage to obtain the maximum value of the estimated volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com