Lorry automatic gearbox crawling control system based on clutch target torque

A technology of automatic transmission and target torque, which is applied in the direction of clutch, transmission control, control device, etc. It can solve the problem of failure to take into account the sensitivity of clutch torque, the inability to achieve coordinated control of engine torque, and the inability to give the driver prompt time and overheating information, etc. problems, to achieve the effect of reducing the amount of friction, low engine speed, and avoiding insufficient power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

[0059] A crawl control system for heavy truck automatic transmissions based on clutch target torque,

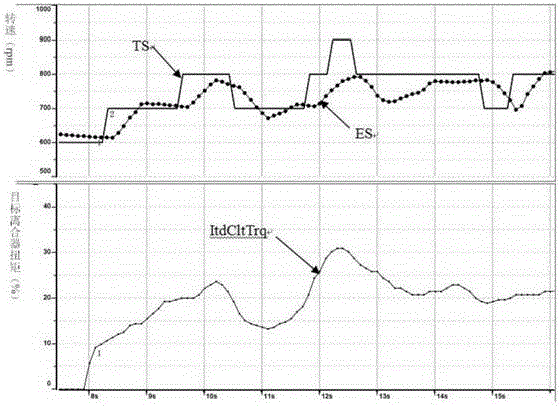

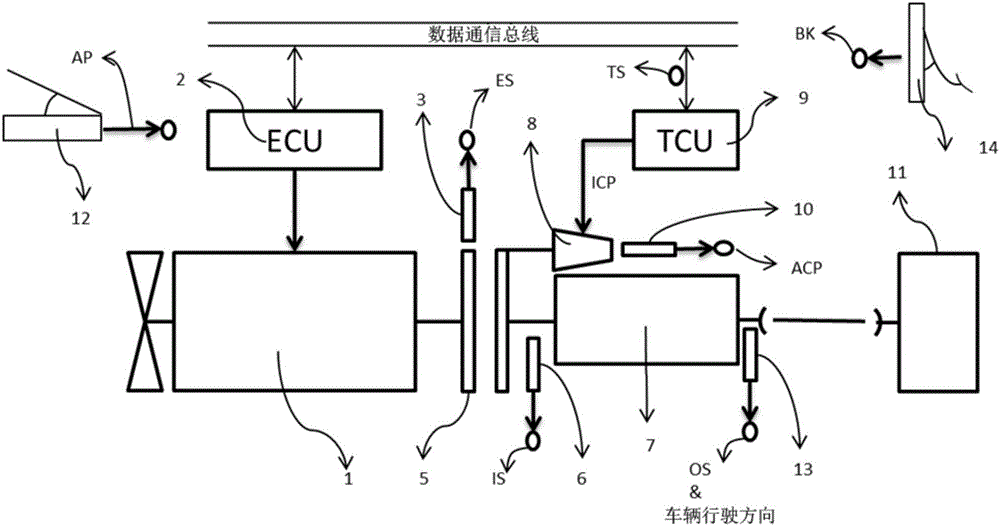

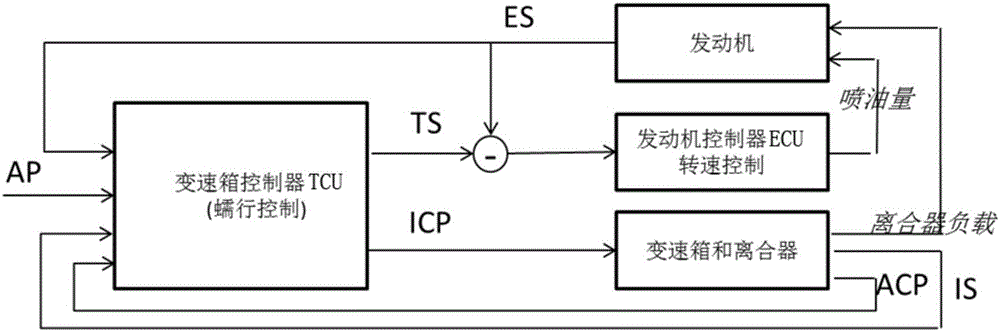

[0060] The vehicle automatic transmission system applicable to this control system shall have the following figure 1 Powertrain structure shown:

[0061] That is, the engine controller ECU2 with the function of speed closed-loop control controls the internal combustion engine 1, and the transmission controller TCU9 controls the clutch booster cylinder 8, the transmission actuator 7 and other vehicle rotation systems 11 including the transmission shaft. The TCU controls the position of the dry friction clutch through the clutch booster cylinder 8 to control the torque transmitted from the engine to the gearbox 7 .

[0062] The control system adds an accelerator pedal sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com